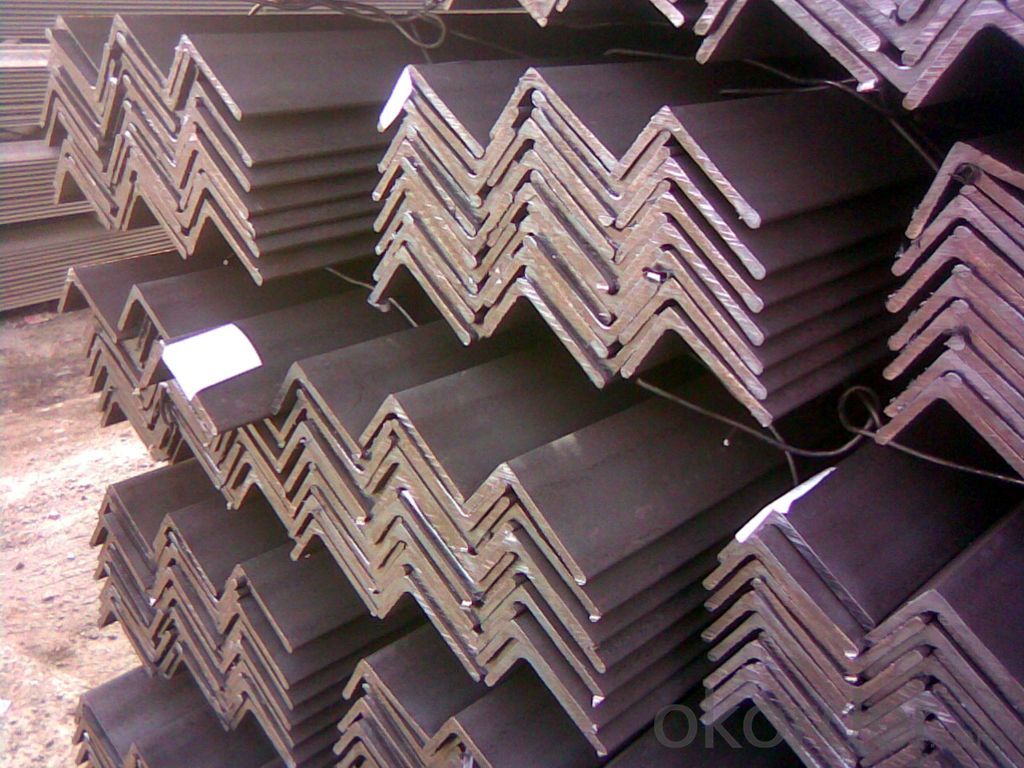

A90*90*8 Equal steel Angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

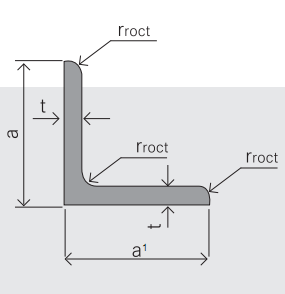

Specifications of Equal Steel Angle

1. Standards: GB,ASTM,BS,AISI,DIN,JIS

2. Length:6m,9m,12m

3. Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192,

SS400; SS540.

4. Sizes:

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Equal Steel Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Steel Angle

- Q: Can steel angles be used in outdoor or corrosive environments?

- Yes, steel angles can be used in outdoor or corrosive environments. Steel angles are often made from low carbon steel or stainless steel, both of which have excellent corrosion resistance properties. Additionally, steel angles can be further protected from corrosion by applying coatings such as galvanization or painting. These protective coatings create a barrier between the steel and the corrosive elements in the environment, preventing rust and degradation. Therefore, steel angles are commonly used in outdoor structures, such as bridges, buildings, and industrial facilities, where they are exposed to moisture, saltwater, or other corrosive elements.

- Q: Can steel angles be used for framing?

- Framing in construction projects can indeed utilize steel angles. These L-shaped metal profiles, also known as angle irons, possess remarkable strength and durability. Their structural stability and capacity to bear heavy loads make them widely employed for framing purposes. Steel angles can be easily manipulated through cutting, welding, and bolting to generate robust frames for diverse structures like buildings, bridges, and industrial facilities. They commonly serve as vertical or horizontal supports, bracing elements, or lintels to ensure stability and structural integrity. Moreover, steel angles can be galvanized or coated to enhance their resistance to corrosion, rendering them suitable for both indoor and outdoor framing applications. In conclusion, steel angles represent a versatile and dependable option for framing in construction projects.

- Q: Can steel angles be used in electrical or telecommunications installations?

- Yes, steel angles can be used in electrical or telecommunications installations. Steel angles are commonly used as structural supports and mounting brackets in these types of installations due to their strength, durability, and versatility.

- Q: What are the dimensions of a standard steel angle?

- The dimensions of a standard steel angle typically include the length of the legs and the thickness of the steel.

- Q: What are the different methods of connecting steel angles together?

- There are several methods of connecting steel angles together, including welding, bolting, riveting, and using angle brackets.

- Q: What are the different methods of surface preparation for painting steel angles?

- Some different methods of surface preparation for painting steel angles include abrasive blasting, chemical cleaning, and power tool cleaning. Abrasive blasting involves using high-pressure air or water to propel abrasive materials onto the surface of the steel angle, removing any rust, scale, or other contaminants. Chemical cleaning involves applying specific chemicals to the steel angle to dissolve or remove any contaminants. Power tool cleaning involves using power tools such as grinders or sanders to mechanically remove any rust, scale, or other contaminants from the surface of the steel angle.

- Q: How do you calculate the deflection of a steel angle?

- To determine the deflection of a steel angle, one must take into account various factors and utilize the correct formulas. Typically, the deflection of a beam or angle is calculated using the Euler-Bernoulli beam theory, which assumes small deflections and a slender beam. Initially, the moment of inertia (I) of the steel angle needs to be calculated. This can be done by considering the dimensions and properties of the angle section. The moment of inertia reflects the angle's resistance to bending. Subsequently, the applied load or force (F) acting on the steel angle should be determined. This could be a concentrated load, distributed load, or a combination of both. The load induces a bending moment (M) on the angle. Once the moment of inertia and the bending moment are established, the formula for deflection in a simply supported beam can be employed: To calculate the deflection at the midpoint of the steel angle (δ), use the following equation: δ = (5 * M * L^4) / (384 * E * I) In this equation: - δ represents the deflection at the midpoint of the steel angle - M denotes the bending moment applied to the angle - L signifies the length of the angle - E represents the modulus of elasticity of the steel material - I indicates the moment of inertia of the angle section By substituting the appropriate values into the formula, one can compute the deflection. It is crucial to ensure that the units are consistent and compatible during the calculation process. However, it is important to note that this calculation assumes linear behavior and disregards factors like shear deformation and lateral torsional buckling. For more precise results, additional factors should be taken into account or engineering resources, such as design codes or software, should be consulted for a more accurate deflection calculation.

- Q: What is the typical thickness of the legs of a steel angle?

- The typical thickness of the legs of a steel angle can vary depending on the specific application and structural requirements. However, in general, the thickness of steel angle legs can range from 1/8 inch to 3/4 inch.

- Q: What are the different types of connections used for steel angles in marine applications?

- Steel angles are commonly utilized in marine applications to provide structural support and reinforcement. To ensure their stability and strength in the harsh marine environment, various types of connections are employed. The different connection methods for steel angles in marine applications include: 1. Welded Connections: Welding is widely used to connect steel angles in marine applications. This method involves melting the base metals and allowing them to cool and solidify, resulting in strong and durable connections. Welded connections are ideal for heavy-duty marine applications due to their excellent strength and durability. 2. Bolted Connections: Another commonly used method is bolted connections, which involve securing the angles together using bolts, nuts, and washers. Bolted connections offer easy installation and allow for disassembly if needed. They are suitable when adjustments or replacements of the angles are required. 3. Riveted Connections: Riveting, an older connection method, is still employed in certain marine applications. It entails using rivets, metal pins with heads, to connect the angles. The rivets are inserted through pre-drilled holes in the angles and deformed to secure them. Riveted connections offer good strength and vibration resistance, but they can be time-consuming to install compared to other methods. 4. Adhesive Connections: Adhesive bonding is a contemporary method used to connect steel angles in marine applications. This method involves utilizing high-strength adhesives to join the angles together. Adhesive connections evenly distribute stress across the connected surfaces and eliminate the need for drilling or welding. However, they require meticulous surface preparation and curing time for optimal strength. 5. Hybrid Connections: In certain cases, a combination of different connection methods may be employed for steel angles in marine applications. For instance, a welded-bolted connection may be used to enhance strength and redundancy. Hybrid connections offer the advantages of multiple connection methods while ensuring a robust and reliable connection. The choice of connection type for steel angles in marine applications depends on factors such as load requirements, environmental conditions, and project specifications. It is crucial to consider the specific needs of the application and consult with structural engineers and marine professionals to determine the most suitable connection method.

- Q: Can steel angles be used for vehicle frames?

- Yes, steel angles can be used for vehicle frames. Steel angles are commonly used in the construction industry for their structural strength and versatility. They have a wide range of applications, including the construction of vehicle frames. Steel angles provide excellent support and stability, making them ideal for bearing heavy loads and withstanding the various stresses and forces experienced by a vehicle during operation. Additionally, steel angles can be easily welded or bolted together, allowing for flexibility in the design and construction of vehicle frames. Overall, steel angles are a reliable and durable choice for vehicle frames, ensuring the structural integrity and safety of the vehicle.

Send your message to us

A90*90*8 Equal steel Angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches