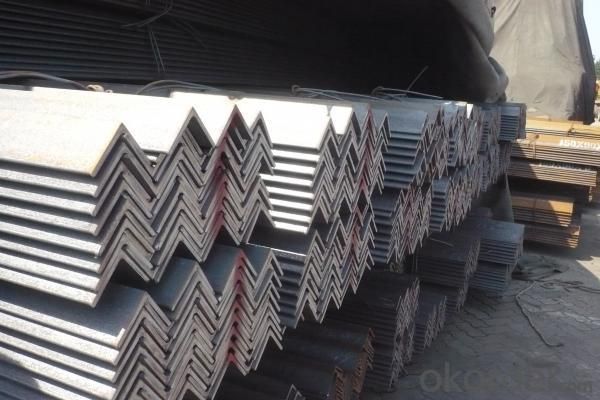

JIS SS400 Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of JIS SS400 Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Invoicing on theoretical weight or actual weight as customer request

3.Material: JIS G3192,SS400;SS540.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Sizes:

EQUAL ANGLES SIZES | |||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material Specifications:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS330 | ≧205 | ≧195 | ≧175 | ≧165 | 330-430 |

SS400 | ≧245 | ≧235 | ≧215 | ≧205 | 400-510 |

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

SS540 | ≧400 | ≧390 | - | - | ≧540 |

Usage & Applications JIS SS400 Angle Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of JIS SS400 Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of JIS SS400 Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel angles be used for manufacturing playground equipment?

- Yes, steel angles can be used for manufacturing playground equipment. Steel angles are commonly used in construction and manufacturing due to their strength and durability. They can be used to create the framework and support structures for various types of playground equipment, such as slides, climbing frames, and swing sets. The versatility of steel angles allows for the creation of safe and sturdy playground equipment that can withstand heavy use and harsh weather conditions. Additionally, steel angles can be easily welded, cut, and shaped to suit specific design requirements, making them an ideal choice for playground equipment manufacturers.

- Q: How do you protect steel angles from moisture?

- There are several measures you can take to protect steel angles from moisture: 1. Applying a protective coating is a highly effective method. By using paint or primer, you create a barrier that prevents direct contact between the steel and moisture, thus avoiding potential corrosion. 2. Another option is galvanization. This involves coating the steel angles with a layer of zinc, which provides excellent protection against moisture. This process creates a sacrificial layer that corrodes before the steel, extending its lifespan. 3. Implementing proper drainage systems is crucial. By installing gutters, downspouts, or using sloping surfaces, you can ensure water does not accumulate around the steel angles, preventing prolonged exposure to moisture. 4. Regular inspection and maintenance are essential. Keep an eye out for signs of moisture buildup, rust, or damage on the steel angles. Take immediate action by cleaning, repairing, or applying additional protective coatings to prevent moisture from seeping in. 5. Consider using moisture-absorbing materials such as desiccants or silica gel packs in the vicinity of steel angles. These materials help reduce humidity levels and prevent moisture buildup. 6. If the steel angles are located in an enclosed space, controlling humidity levels is crucial. Ensure proper ventilation and use dehumidifiers or fans to reduce moisture and prevent condensation on the steel surfaces. By following these preventive measures, you can effectively safeguard steel angles from moisture, increasing their lifespan and preventing corrosion.

- Q: Can steel angles be used for supporting mechanical equipment?

- Indeed, mechanical equipment can be effectively supported using steel angles. In construction and engineering endeavors, steel angles are frequently employed owing to their robustness, resilience, and adaptability. They furnish a steady and inflexible support framework for a wide array of mechanical equipment such as weighty machinery, conveyors, and support frames. Notably, steel angles are acclaimed for their capacity to bear weight, rendering them optimal for furnishing structural support in industrial settings. Furthermore, their L-shaped configuration facilitates effortless equipment installation and attachment. All in all, steel angles are a trustworthy and prevalent choice for bolstering mechanical equipment due to their strength, durability, and user-friendliness.

- Q: What are the advantages of using steel angles over other materials?

- There are several advantages of using steel angles over other materials. Firstly, steel angles offer exceptional strength and durability, making them suitable for a wide range of structural applications. They can withstand heavy loads and provide reliable support, ensuring structural integrity. Additionally, steel angles are versatile as they can be easily customized and fabricated to meet specific design requirements. They are also cost-effective in terms of long-term maintenance and repair, as steel is highly resistant to corrosion and requires minimal upkeep. Lastly, steel angles offer excellent fire resistance, making them a safe choice for construction projects.

- Q: Can steel angles be used in the construction of industrial chimneys?

- Yes, steel angles can be used in the construction of industrial chimneys. Steel angles provide structural support and stability to the chimney, making them a common choice in industrial construction projects.

- Q: What are the design considerations when using steel angles?

- When incorporating steel angles into design, there are several important factors to keep in mind. Firstly, the load-bearing capacity of the steel angles must be thoroughly evaluated. The anticipated loads and stresses that the structure will endure should dictate the selection of the appropriate size, thickness, and configuration of the angles. Another factor to consider is the structural integrity of the connections between the steel angles and other design elements. The connections must be designed to provide sufficient strength and stiffness, while also accommodating any potential movement or deformation of the angles. The potential for corrosion when using steel angles should also be taken into account. To prevent rust and deterioration, it is essential to apply suitable protective coatings or treatments, especially in outdoor or high-moisture environments. Aesthetics and visual appeal are also significant considerations in design. The shape, finish, and overall appearance of the steel angles should align with the desired aesthetic of the project, whether it is a modern, industrial look or a more traditional and ornamental design. Finally, cost and availability should be considered when incorporating steel angles. The project's overall budget should be weighed against the cost of materials, fabrication, and installation. Additionally, it is important to consider the availability of the desired sizes and configurations of steel angles to ensure a smooth and timely construction process. By carefully considering these design factors, designers can effectively integrate steel angles into their projects, guaranteeing structural integrity, aesthetic appeal, and cost-effectiveness.

- Q: Can steel angles be used for ladder rungs?

- Ladder rungs can indeed utilize steel angles, as they boast strength and durability, making them a frequent choice in construction and fabrication. Utilizing steel angles as rungs ensures a solid and secure surface for ladder climbing. Nonetheless, it is crucial to consider the precise requirements and regulations for ladder rungs, including dimensions, spacing, and anti-slip properties. These factors guarantee user safety and ladder stability. It is advisable to consult applicable safety guidelines and standards prior to employing steel angles as ladder rungs.

- Q: Are steel angles available in non-standard sizes or custom shapes?

- Yes, steel angles are available in non-standard sizes and can be custom made to specific shapes based on the requirements of the project or design.

- Q: What is the lifespan of steel angles?

- The lifespan of steel angles can vary depending on a range of factors including the quality of the steel, the environment in which they are used, and the level of maintenance they receive. Generally speaking, steel angles are known for their durability and longevity, making them a popular choice in construction and structural applications. High-quality steel angles that are properly manufactured and maintained can last for several decades or even longer. However, factors such as exposure to harsh weather conditions, corrosive environments, and lack of maintenance can significantly reduce their lifespan. To maximize the lifespan of steel angles, it is important to choose the appropriate grade of steel for the specific application, ensure proper installation, and regularly inspect and maintain them. This may include measures such as periodically painting or coating the angles to protect them from corrosion, conducting routine inspections to identify any signs of wear or damage, and promptly addressing any issues that arise. In summary, the lifespan of steel angles can vary but with proper care and maintenance, they can last for many years, providing strength and stability to various structures and applications.

- Q: Can steel angles be used as bracing elements in buildings?

- Yes, steel angles can be used as bracing elements in buildings. Steel angles are commonly used in construction for their strength and versatility. They are often used as structural components to provide lateral stability and support to buildings. Steel angles can be used as bracing elements to resist horizontal loads such as wind or seismic forces, helping to prevent excessive movement or deformation of the structure. They are typically installed at strategic locations, such as corners or intersections, and can be connected to other structural members using bolts or welds. Steel angles are preferred for bracing due to their high strength-to-weight ratio, durability, and ease of installation. Overall, steel angles are a reliable and commonly used solution for bracing elements in buildings.

Send your message to us

JIS SS400 Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords