Hot Rolled Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

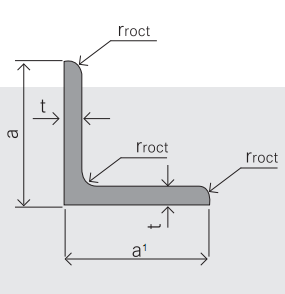

Specifications of Equal Angle

1. Standards: GB,ASTM,BS,AISI,DIN,JIS

2. Length:6m,9m,12m

3. Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400;

SS540.

4. Sizes:

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Chemical data: %

C | Mn | S | P | Si |

0.14-0.22 | 0.30-0.65 | ≤0.050 | ≤0.045 | ≤0.30 |

Usage & Applications of Equal Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

- Q: What is the maximum length of a steel angle that can be transported?

- The maximum length of a steel angle that can be transported depends on various factors, including transportation regulations and limitations, the size and capacity of the transport vehicle, and any logistical constraints. In general, standard transport vehicles like trucks or trailers can typically accommodate steel angles up to a certain length, often around 40 feet (12.2 meters). These vehicles may have limitations on the length of cargo they can carry due to road transportation regulations or physical constraints. However, it's important to note that specialized transport options, such as flatbed trucks or lowboy trailers, may be available to accommodate longer steel angles. These specialized vehicles are designed to carry oversized or heavy loads and may have extended cargo beds or adjustable trailers to accommodate longer lengths. Ultimately, the maximum length of a steel angle that can be transported will vary depending on the specific circumstances and available transport options. It is recommended to consult with transportation professionals or logistics experts to determine the best and most suitable means of transporting steel angles of varying lengths.

- Q: Can steel angles be used in marine environments?

- Indeed, the utilization of steel angles is viable in marine environments. Given their robustness and adaptability, steel angles are widely employed in the construction sector. However, the presence of corrosive elements and exposure to saltwater necessitates the use of materials that are resistant to corrosion. Therefore, in marine applications, it is imperative to opt for stainless steel angles or galvanized steel angles as they possess exceptional resistance against corrosion. These materials are equipped with protective coatings or alloys that effectively prevent rusting and deterioration, thereby ensuring their endurance and longevity in marine environments. Furthermore, steel angles can be custom designed and fabricated to adhere to specific requirements and regulations governing marine structures, including shipbuilding, offshore platforms, and marine piers.

- Q: Can steel angles be used for decorative purposes?

- Yes, steel angles can definitely be used for decorative purposes. They can be shaped and designed in various ways to add a modern and industrial touch to interior or exterior spaces. Steel angles can be used as decorative accents, such as in furniture design, architectural details, or even as standalone decorative pieces. Their durability and versatility make them an excellent choice for adding a unique and stylish element to any space.

- Q: How are steel angles installed?

- Steel angles are typically installed using a few simple steps. First, you will need to mark the desired location for the angle on the surface or structure where it will be installed. Next, using a level and measuring tape, ensure that the angle is aligned correctly and mark the positions for the screw or bolt holes. Once the markings are made, you will need to pre-drill the holes using a drill bit that is slightly smaller than the diameter of the screws or bolts you will be using. This will prevent the steel angle from cracking or splitting during installation. After pre-drilling the holes, place the steel angle back in position and align the holes with the markings on the surface. Use a wrench or screwdriver to tighten the screws or bolts securely, making sure the angle is firmly attached. It is important to follow the manufacturer's instructions and recommendations for the specific type and size of steel angle being installed. Additionally, ensure that the surface or structure where the angle is being installed is able to support the weight and load that will be applied to it. Overall, steel angles are relatively simple to install and provide excellent structural support in various applications such as construction, manufacturing, and DIY projects.

- Q: Are steel angles resistant to chemical corrosion?

- Steel angles have some resistance to chemical corrosion. Although steel is generally strong and durable, it can still corrode in the presence of certain chemicals and corrosive environments. However, steel angles are often treated or coated with protective materials like galvanization, which greatly improves their resistance to chemical corrosion. Galvanized steel angles have a zinc layer on their surface that acts as a barrier against corrosive substances. This coating helps prevent direct contact between the steel and chemicals, reducing the risk of corrosion. It's important to note, though, that the level of resistance may vary depending on the specific chemical, as well as the duration and intensity of exposure. To ensure long-term corrosion resistance, regular maintenance and inspection of steel angles are necessary.

- Q: What is the minimum radius for a curved steel angle beam?

- The minimum radius for a curved steel angle beam depends on various factors such as the size and thickness of the angle beam, the type of steel used, and the specific application requirements. It is recommended to consult structural engineers or refer to relevant design codes and standards for the specific project to determine the appropriate minimum radius for a curved steel angle beam.

- Q: Can steel angles be used for roof trusses?

- Yes, steel angles can be used for roof trusses. Steel angles are commonly used in construction for their strength and durability. They can be easily fabricated and installed to create the framework for roof trusses. Steel angles provide excellent support and stability, making them suitable for use in various roofing applications. Additionally, steel angles can withstand heavy loads and adverse weather conditions, making them a reliable choice for roof trusses.

- Q: Can steel angles be used for outdoor applications?

- Yes, steel angles can be used for outdoor applications. Steel angles are made from a strong and durable material, making them suitable for various outdoor projects. They are commonly used in construction, infrastructure, and engineering projects that require structural support or reinforcement. Steel angles can withstand harsh weather conditions, such as rain, snow, and direct sunlight, without deteriorating or losing their strength. Additionally, steel angles can be coated or treated to increase their resistance to corrosion, further enhancing their suitability for outdoor applications. Overall, steel angles are a reliable and versatile choice for outdoor projects that require strength, durability, and long-term performance.

- Q: Can steel angles be galvanized or coated for corrosion resistance?

- Yes, steel angles can be galvanized or coated with a protective layer for corrosion resistance. Galvanizing involves applying a zinc coating to the steel surface, while coating can involve various materials such as paint or powder coating. These treatments help to prevent rust and enhance the longevity and durability of steel angles in corrosive environments.

- Q: What is the difference between galvanized and black steel angles?

- Galvanized and black steel angles are two types of steel angles that have distinct characteristics and uses. Galvanized steel angles are coated with a layer of zinc, which provides protection against corrosion. The process of galvanization involves immersing the steel angles in a bath of molten zinc, allowing the zinc to bond with the steel surface. This protective zinc coating increases the longevity and durability of the steel angles, making them resistant to rust and other forms of corrosion. Galvanized steel angles are commonly used in outdoor applications, such as construction projects, fencing, and marine environments where exposure to moisture and harsh weather conditions is a concern. On the other hand, black steel angles do not have any protective coating. They are simply made from raw steel, which gives them a black appearance. Black steel angles are typically used in indoor applications, such as structural support, framing, and general fabrication. Since they are not protected against corrosion, they are not suitable for outdoor use or environments with high moisture content. In summary, the main difference between galvanized and black steel angles lies in their coating and corrosion resistance. Galvanized steel angles have a zinc coating that protects them from rust and corrosion, making them suitable for outdoor applications. Black steel angles, on the other hand, lack any protective coating and are primarily used indoors for structural support and general fabrication purposes.

Send your message to us

Hot Rolled Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords