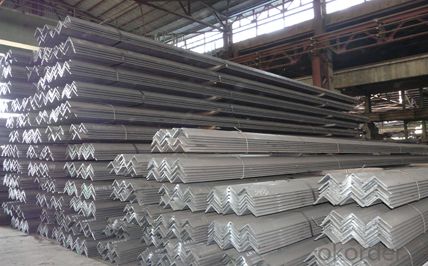

Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

1.Manufacturer

2. High quality, sincere service, fair price

3. Excellent Performance

Different Sizes of Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

| StandardSectional Dimension mm | Weight kg/m | StandardSectional Dimension mm | Weight kg/m |

| 25*25*3 | 1.12 | 90*90*6 | 8.28 |

| 30*30*3 | 1.36 | 90*90*7 | 9.59 |

| 40*40*3 | 1.83 | 90*90*10 | 13.3 |

| 40*40*5 | 2.95 | 100*100*7 | 10.7 |

| 45*45*4 | 2.74 | 100*100*10 | 14.9 |

| 45*45*5 | 3.38 | 100*100*13 | 19.1 |

| 50*50*4 | 3.06 | 120*120*8 | 14.7 |

| 50*50*6 | 4.43 | 130*130*9 | 17.9 |

| 60*60*4 | 3.68 | 130*130*12 | 23.4 |

| 60*60*5 | 4.55 | 130*130*15 | 28.8 |

| 60*60*6 | 5.37 | 150*150*12 | 27.3 |

| 65*65*6 | 5.91 | 150*150*15 | 33.6 |

| 65*65*8 | 7.66 | 150*150*19 | 41.9 |

| 70*70*6 | 6.38 | 175*175*12 | 31.8 |

| 75*75*6 | 6.85 | 175*175*15 | 39.4 |

| 75*75*6 | 9.96 | 200*200*15 | 45.3 |

| 80*80*6 | 7.32 | 200*200*20 | 59.7 |

| 80*80*7 | 8.48 | 200*200*25 | 73.6 |

Product Specification of Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

| Product | Equal Steel Angle Steel Galvanized SS400 Best Angle Steel |

| Product classification | Equal Angle Steel & Unequal Angle Steel |

| Production Technics | Hot rolled,cold-bend |

| Productivity | 300,000 Mt/Year |

| Main Material | SS400,Q235A,Q235B,Q345,Q345B,ASTM A36,S235JR,ST37,Stainless steel series,etc |

| Surface treatment | hot dip galvanised or cold dip galvanised |

| Specification | (20*20*2mm)-(200*200*25mm) |

| Theoretical weight per meter | =0.00785*(width+width-thickness)*thickness |

| Application | widely used in Power tower, communication tower, railway, highway, street lamp pole, marine parts, construction steel structure component, handling machinery ,Container frame , warehouse ,reaction tower,the substation ancillary facilities, light industry etc. |

| Length | 6m-12m as you require |

Applications of Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

1. Pipe and Tubes for petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

Advantages of Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

We have both advanced production line, and advanced quality detecting, such as HLGER read-directlys

pectrum instrument, infrared CS analysis instrument, which can do ultrasonic test, crystal corrosion test and

metallographic test.

- Q: How do you calculate the strength of a steel angle?

- To calculate the strength of a steel angle, you typically need to consider several factors, including the dimensions of the angle, the material properties of the steel, and the applied loads. The strength can be determined using mathematical equations, such as the yield strength or ultimate strength equations, which take into account the cross-sectional area and moment of inertia of the angle. Additionally, other factors like buckling or lateral torsional buckling may also need to be considered depending on the specific design requirements.

- Q: Can steel angles be used in telecommunications or broadcasting structures?

- Yes, steel angles can certainly be used in telecommunications or broadcasting structures. Steel angles provide structural support and stability, making them ideal for constructing towers, antennas, and other infrastructure required for telecommunications and broadcasting purposes.

- Q: What are the tolerances for steel angles?

- The tolerances for steel angles can vary depending on the specific requirements and industry standards. However, common tolerances for steel angles typically include variations in dimensions, such as length, width, and thickness, within a certain range specified by the relevant standards or specifications. These tolerances ensure that the angles meet the required specifications and can be used effectively in various applications.

- Q: How do steel angles compare to other materials like aluminum or wood?

- Steel angles are typically stronger and more durable than materials like aluminum or wood. They have a higher load-bearing capacity and can withstand greater amounts of stress and pressure. Additionally, steel angles are resistant to warping, rotting, and termite infestation, which are common issues with wood. However, steel angles are generally heavier and more expensive compared to aluminum. The choice between steel angles and other materials depends on the specific requirements of the project, such as strength, cost, and environmental factors.

- Q: How do steel angles perform under extreme temperatures?

- Under extreme temperatures, steel angles generally have a good performance. Steel possesses a high thermal conductivity, enabling it to rapidly absorb and distribute heat. This characteristic aids in the steel angles' ability to endure extreme temperatures without significant deformation or failure. However, it is important to acknowledge that the actual performance of steel angles in extreme temperatures can vary due to factors like the alloy composition and heat treatment of the steel. In certain instances, steel angles may experience a decrease in strength or an increased susceptibility to corrosion at extremely high temperatures. Therefore, it is advisable to seek advice from a materials engineer or refer to the manufacturer's specifications to ascertain the specific performance of steel angles under the desired extreme temperature conditions.

- Q: Is there a screw that can be made like angle iron, but not a right angle, just a single piece of material? That's the way to break the angle iron in two. What if it's called? Thank you, professionals!

- Wear protective gloves and glasses when cutting, because metal chips can hurt people, especially the eyes. Ha ha, I hope to help you.

- Q: Are steel angles suitable for vehicle ramps?

- Yes, steel angles are suitable for vehicle ramps. Steel angles are commonly used in construction and are known for their strength and durability. They provide a sturdy and stable surface for vehicles to drive on, making them a suitable choice for vehicle ramps. Additionally, steel angles can be easily welded or bolted together to create a customized ramp design that meets specific requirements. Overall, steel angles are a reliable and practical option for constructing vehicle ramps.

- Q: Can steel angles support heavy machinery or equipment?

- Yes, steel angles can support heavy machinery or equipment. Steel angles are commonly used in structural applications due to their high strength and durability. They provide excellent support and stability, making them suitable for handling heavy loads.

- Q: What is the standard size of steel angles?

- The standard size of steel angles can vary depending on the specific application and industry requirements. However, common standard sizes for steel angles typically range from 1/2 inch to 8 inches in width and height, with a thickness that can range from 1/8 inch to 1 inch.

- Q: How do steel angles perform under static or stationary loading conditions?

- Steel angles are commonly used in construction and engineering applications due to their strength and versatility. Under static or stationary loading conditions, steel angles exhibit excellent performance and stability. Static loading refers to a situation where a load is applied to the angle and remains constant without any motion. Steel angles are specifically designed to withstand such loading conditions. Due to their structural properties, steel angles have a high resistance to bending and twisting forces. This allows them to effectively support heavy loads without experiencing significant deformation or failure. Steel angles distribute the applied load evenly along their length, which helps to minimize stress concentrations. This property ensures that the angle can efficiently transfer the load to the supporting structure, providing stability and structural integrity. Additionally, steel angles can withstand compressive forces, which try to shorten or compress the material. The shape and cross-section of steel angles, specifically their L-shaped profile, contribute to their ability to resist compressive loading. This feature makes steel angles suitable for applications where static loads exert compressive forces, such as columns, beams, and bracing elements. Moreover, steel angles have a high resistance to shear forces, which occur when two or more parts of a structure slide or move in opposite directions. The design of steel angles, with their perpendicular legs, enhances their shear strength, allowing them to effectively resist shear loading under stationary conditions. In summary, steel angles perform exceptionally well under static or stationary loading conditions. Their structural properties, such as resistance to bending, twisting, compression, and shear forces, make them suitable for a wide range of applications in construction and engineering.

Send your message to us

Equal Steel Angle Steel Galvanized SS400 Best Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords