Equal Angle Steel Hot Rolled SS400-SS540 Series

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

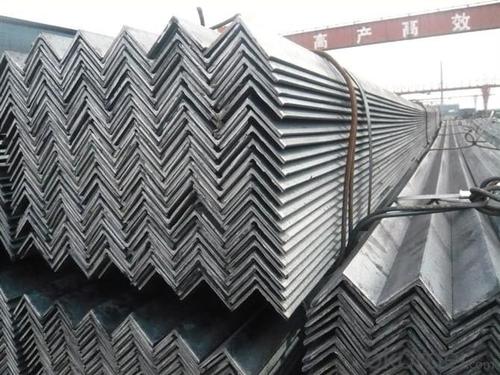

OKorder is offering Equal Angle Steel Hot Rolled SS400-SS540 Series at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal Angle Steel Hot Rolled SS400-SS540 Series are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Equal Angle Steel Hot Rolled SS400-SS540 Series are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Equal Angle Steel

1) Size:20-250mm,

Thickness:3-16mm,length:6-12m

2) Material: Q195/235/345, SS400,ST37-2,ASTM A36

Equal angle steel

1.Standard: GB, ASTM, JIS, DIN.ect

2.Grade: Q195,Q235,Q345,A36,SS400, ST37-2.ect

3.Specification: 20*20--200*200mm. Thickness: 3-24mm.Length: common length 5.8m, 6m,11.8m,12m

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5. Packing: with bundles and load in 20 feet/40 feet container, or by bulk cargo( if with large quantity), also we could do as customer's request.

If you have any other demand, pls contact me freely. Hope our products will work for your business.

Reference sizes, pls check it as below,

Size | Theoretical weight | Size | Theoretical weight | Size | Theoretical weight |

(mm) | (kg/m) | (mm) | (kg/m) | (mm) | (kg/m) |

25*3 | 1.124 | 70*6 | 6.406 | 100*16 | 23.257 |

25*4 | 1.459 | 70*7 | 7.398 | 110*8 | 13.532 |

30*3 | 1.373 | 70*8 | 8.373 | 110*10 | 16.69 |

30*4 | 1.786 | 75*5 | 5.818 | 110*12 | 19.782 |

40*3 | 1.852 | 75*6 | 6.905 | 110*14 | 22.809 |

40*4 | 2.422 | 75*7 | 7.976 | 125*8 | 15.504 |

40*5 | 2.967 | 75*8 | 9.03 | 125*10 | 19.133 |

50*3 | 2.332 | 75*10 | 11.089 | 125*12 | 22.696 |

50*4 | 3.059 | 80*6 | 7.736 | 125*14 | 26.193 |

50*5 | 3.77 | 80*8 | 9.658 | 140*10 | 21.488 |

50*6 | 4.465 | 80*10 | 11.874 | 140*12 | 25.522 |

60*5 | 4.57 | 90*8 | 10.946 | 140*14 | 29.49 |

60*6 | 5.42 | 90*10 | 13.476 | 160*12 | 29.391 |

63*4 | 3.907 | 90*12 | 15.94 | 160*14 | 33.987 |

63*5 | 4.822 | 100*8 | 12.276 | 160*16 | 38.518 |

63*6 | 5.721 | 100*10 | 15.12 | 160*18 | 48.63 |

63*8 | 7.469 | 100*12 | 17.898 | 180*18 | 48.634 |

70*5 | 5.397 | 100*14 | 20.611 | 200*24 | 71.168 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: How many kilograms per square meter is angle steel 63*63*6?

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm. Also available models that model is the number of centimeters wide, such as angle 3#. The model does not mean the size of the different edges and sizes of the same model. Therefore, the width, the edge and the thickness of the angle iron should be filled out in the contract and other documents, so as not to be indicated by the model alone. Standard Specification for hot-rolled equal angle iron is 2#-20#.

- Q: What are the different methods of surface painting for steel angles?

- There are several different methods of surface painting for steel angles, each offering unique benefits and considerations. 1. Brushing: This is the most common method of surface painting for steel angles. It involves using a paintbrush to manually apply paint onto the surface. Brushing allows for good control and precision, making it ideal for smaller projects or touch-ups. However, it may not be as efficient for large-scale applications. 2. Spraying: Spraying is a popular method for painting steel angles, especially when a large area needs to be covered quickly. It involves using a paint spray gun or aerosol canister to evenly distribute paint onto the surface. Spraying allows for a smooth and uniform finish, but it requires appropriate safety precautions, such as wearing a mask and ensuring proper ventilation. 3. Dipping: Dipping involves immersing the steel angles in a tank or container filled with paint. This method ensures complete coverage and is often used for high-volume production processes. However, it may not be suitable for complex shapes or angles with intricate designs, as the excess paint may drip or accumulate unevenly. 4. Electrostatic painting: Electrostatic painting is a method that involves charging the paint particles and applying them to a grounded steel angle. This creates an electromagnetic attraction, resulting in a more even and efficient coverage. Electrostatic painting is commonly used in industrial settings and can help reduce paint waste and overspray. 5. Powder coating: Powder coating is a dry finishing process that involves applying a fine powder onto the steel angle's surface. The powder is then heated and fused onto the metal, creating a durable and attractive finish. Powder coating provides excellent corrosion resistance and can be done in a variety of colors and textures. However, it requires specialized equipment and may not be suitable for small-scale or on-site applications. When selecting a method of surface painting for steel angles, it is important to consider factors such as the size and complexity of the project, desired finish quality, environmental conditions, and available resources. Consulting with a professional painter or coating specialist can help determine the most suitable method for a specific application.

- Q: How do you reinforce a steel angle?

- There are several methods to reinforce a steel angle, depending on the specific application and requirements. Here are a few common techniques: 1. Welded Plates: One way to reinforce a steel angle is by adding welded plates at critical locations. These additional plates are typically made of the same or higher strength steel and are welded to the angle's flanges or web. This method increases the overall stiffness and load-bearing capacity of the angle. 2. Gusset Plates: Another effective method to reinforce a steel angle is by using gusset plates. These plates are typically triangular-shaped and are welded to the angle's flanges or web. Gusset plates distribute forces more evenly across the angle, increasing its strength and resistance to bending or torsion. 3. Bracing: Bracing is a technique used to reinforce a steel angle by adding additional steel members to it. These members can be either connected directly to the angle or attached using welded or bolted connections. Bracing effectively increases the angle's resistance to lateral or torsional forces and enhances its overall stability. 4. Composite Materials: In some cases, reinforcing a steel angle can be achieved by adding composite materials. Fiber-reinforced polymers (FRPs) or carbon fiber reinforced polymers (CFRPs) can be used to wrap or bond to the angle, providing additional strength and stiffness. These composite materials can significantly improve the angle's load-carrying capacity and resistance to corrosion. It is crucial to consult with a structural engineer or a professional with expertise in steel structures to determine the most suitable method for reinforcing a steel angle in a specific application. The chosen reinforcement technique must consider the expected loads, the angle's geometry, and the desired level of reinforcement.

- Q: What is the typical ductility of steel angles?

- The typical ductility of steel angles varies depending on the specific grade of steel used and the manufacturing process. However, in general, steel angles are known to possess excellent ductility. Ductility refers to the ability of a material to deform under tensile stress without fracturing. Steel, including steel angles, is known for its high ductility, which allows it to be easily formed, bent, or twisted without breaking. This characteristic makes steel angles highly versatile and suitable for various applications, such as construction, engineering, and manufacturing.

- Q: How do you determine the required angle thickness for a specific application?

- To determine the required angle thickness for a specific application, several factors need to be considered. These include the load and weight it needs to support, the material properties, the application's safety requirements, and any applicable building codes or regulations. Additionally, factors like the angle's length and shape, the type of fasteners used, and potential environmental conditions should also be taken into account. Consulting engineering guidelines, conducting structural calculations, and seeking professional advice can help in determining the appropriate angle thickness for a specific application.

- Q: What are the common sizes and dimensions of steel angles?

- The common sizes and dimensions of steel angles vary depending on the specific application and industry standards. However, there are some standard sizes that are commonly used in construction and structural engineering. One of the most common sizes of steel angles is the equal angle, which has two sides of equal length and a 90-degree angle between them. These angles are typically available in sizes ranging from 20x20mm to 200x200mm, with thicknesses varying from 3mm to 20mm. The length of equal angles can range from 6 meters to 12 meters, but shorter lengths may also be available. Another common type of steel angle is the unequal angle, which has two sides of different lengths and a 90-degree angle between them. The sizes and dimensions of unequal angles can vary significantly, depending on the specific requirements of the project. However, some common sizes for unequal angles range from 40x25mm to 200x150mm, with thicknesses ranging from 3mm to 15mm. Similar to equal angles, the length of unequal angles can also vary but is typically between 6 meters and 12 meters. It is important to note that these dimensions are not exhaustive and other sizes may be available depending on the manufacturer and the specific needs of the project. Additionally, steel angles can also be custom fabricated to meet unique design requirements. Overall, steel angles are versatile structural components that can be used in various applications, such as framing, support structures, and bracing. The choice of size and dimensions depends on factors such as load capacity, structural requirements, and aesthetic preferences.

- Q: Can steel angles be used for decorative trims?

- Yes, steel angles can be used for decorative trims. Steel angles are versatile and can be cut, shaped, and fabricated to create various decorative elements. They can be used to add a modern and industrial touch to interior or exterior spaces. Steel angles can be painted or powder coated in a wide range of colors to match the desired aesthetic. They can be used as decorative trims around windows, doors, cabinets, furniture, or as accent pieces on walls or ceilings. The durability and strength of steel angles make them a long-lasting and low-maintenance option for decorative trims.

- Q: Can steel angles be used in mezzanine or raised platform constructions?

- Mezzanine or raised platform constructions can incorporate steel angles, which are flexible structural elements capable of providing support and stability in construction projects. Due to their strength and ability to bear heavy loads, steel angles are frequently utilized as framing members in mezzanine or raised platform structures. Their connection to other steel components like beams and columns is effortless, enabling the creation of a robust framework for the mezzanine or raised platform. Moreover, steel angles can serve as bracing and reinforcement elements, thereby enhancing the structure's overall stability and safety. In summary, steel angles are a commonly chosen option for mezzanine or raised platform constructions due to their durability, versatility, and cost-effectiveness.

- Q: Can steel angles be used in mezzanine construction?

- Certainly! Steel angles hold the potential to be utilized in mezzanine construction. Owing to their robustness and adaptability, steel angles are frequently employed as foundational components in construction. Within mezzanine construction, these steel angles can be employed as framing elements to uphold the floor or platform of the mezzanine. Additionally, they can be employed to establish the structure for the stairs or railing systems. By contributing stability and support to the mezzanine structure, steel angles have gained popularity as a favored option in this form of construction.

- Q: Can steel angles be used for staircases or handrails?

- Staircases and handrails can indeed utilize steel angles. These angles, known for their resilience and durability, are highly versatile and frequently employed in construction. Regarding staircases, steel angles can serve as stringers, delivering stability and supporting the steps. Furthermore, they can function as handrails, providing a reliable grip and aiding individuals utilizing the staircase. By welding or bolting steel angles in place, one can ensure a secure and enduring installation for staircases and handrails. Moreover, steel angles can be tailored to meet specific design prerequisites, enabling the creation of visually appealing and practical staircases and handrails with flexibility.

Send your message to us

Equal Angle Steel Hot Rolled SS400-SS540 Series

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords