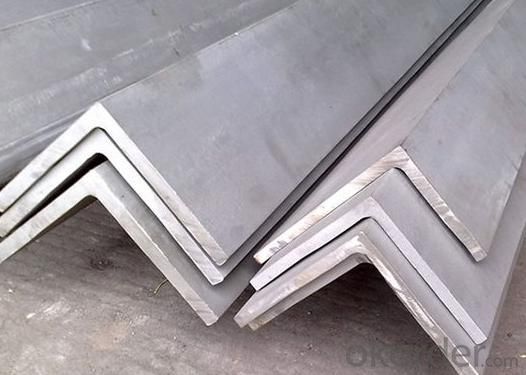

Best Quality for 304 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Angles

General Information of Stainless Steel Angles

1. Grade: SS200, 300,400 series

2. Size: 25×25×3 mm-100×100×10mm

3. Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package: Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry and so on.

Specification of Stainless Steel Angles

Name | Stainless Steel Angles | |||||

Standard | ASTM A554, A312, A249, A269 and A270 | |||||

Material Grade | 304,316,201,202, 316L,430 | |||||

Length | 6m or as customers' request | |||||

Tolerance | a) Thickness: +/-0. 15mm | |||||

b) Length: +/-4. 5mm - 0mm | ||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | |||||

Application | Decoration construction, upholstery, industry instruments | |||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | |||||

Chemical Composition of Material | Composition Material | 201 | 202 | 304 | 316 | 430 |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | |

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | |

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | ||

Mo | 2.0-3.0 | |||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316 | |

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

Hardness (HV) | <253 | <253 | <200 | <200 | ||

- Q: Are stainless steel angles resistant to phosphoric acid?

- Yes, stainless steel angles are generally resistant to phosphoric acid due to their high corrosion resistance properties.

- Q: How do stainless steel angles contribute to the overall sustainability of a structure?

- Stainless steel angles contribute to the overall sustainability of a structure primarily due to their durability and recyclability. Stainless steel is known for its high corrosion resistance and strength, which reduces the need for frequent replacements or repairs. This longevity minimizes material waste and extends the lifespan of the structure. Additionally, stainless steel is fully recyclable, making it a sustainable choice as it can be reused and repurposed at the end of its life cycle. This reduces the demand for new raw materials and decreases environmental impact, making stainless steel angles an eco-friendly option for sustainable construction.

- Q: Can stainless steel angles be used in agricultural machinery?

- Yes, stainless steel angles can be used in agricultural machinery. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for various applications in the agricultural industry. Stainless steel angles can be used in the construction of machinery frames, supports, brackets, and other structural components. The excellent strength and resistance to rust and corrosion make stainless steel angles ideal for withstanding the harsh conditions and exposure to moisture and chemicals commonly found in agricultural environments. Additionally, stainless steel is easy to clean and maintain, ensuring a longer lifespan for the machinery.

- Q: How does stainless steel angle perform in extreme temperature variations?

- Stainless steel angle performs exceptionally well in extreme temperature variations. One of the key properties of stainless steel is its ability to withstand both high and low temperatures without compromising its structural integrity. This is due to its unique composition, primarily consisting of iron, chromium, and nickel, which provides it with excellent heat resistance. In high-temperature environments, stainless steel angle can resist oxidation and maintain its strength. The chromium content in stainless steel forms a protective oxide layer on its surface, shielding it from corrosion and preventing the steel from weakening. This makes stainless steel angle suitable for various applications that involve exposure to extreme heat, such as industrial furnaces, exhaust systems, and high-temperature processing equipment. On the other hand, stainless steel angle also performs well in low-temperature conditions. It retains its toughness and ductility even at freezing temperatures, making it suitable for applications in industries like cryogenics, refrigeration, and cold storage. Stainless steel's resistance to brittleness and its ability to maintain its mechanical properties at low temperatures ensure its reliability and durability in extreme cold environments. Overall, stainless steel angle is a reliable choice for applications that require withstanding extreme temperature variations. Its exceptional heat resistance and ability to maintain its structural integrity in both high and low temperatures make it a versatile material in various industries.

- Q: Can stainless steel angles be used in power plants?

- Yes, stainless steel angles can be used in power plants. Stainless steel is a highly durable and corrosion-resistant material, which makes it ideal for use in power plants where various chemicals and high temperatures are present. Stainless steel angles are commonly used in power plant applications such as structural supports, frames, and platforms. They can also be used for piping systems, heat exchangers, and other components where strength and corrosion resistance are essential. Additionally, stainless steel angles offer excellent mechanical properties, including high tensile strength and resistance to impact and vibration, making them suitable for heavy-duty applications in power plants.

- Q: Can stainless steel angles be used in food and beverage industries?

- Stainless steel angles are indeed suitable for utilization in the food and beverage sectors. The reason behind the popularity of stainless steel in this particular domain lies in its exceptional resistance to corrosion, its hygienic attributes, and its ability to endure high temperatures. Stainless steel angles are frequently employed in the construction of various equipment and structures, including food processing machinery, conveyor systems, storage tanks, and countertops. These angles possess the advantage of being easily cleaned and sanitized, while their smooth surfaces prevent the accumulation of bacteria, rendering them highly suitable for application in the food and beverage industries where cleanliness and hygiene are of utmost importance. Moreover, stainless steel is non-reactive, ensuring that it does not interact with the food or beverages, thus preserving the quality and taste of the products.

- Q: How do stainless steel angles compare to other types of angles?

- Stainless steel angles are highly regarded for their superior strength, durability, and corrosion resistance, making them a preferred choice in various industries. When comparing stainless steel angles to other types of angles, such as aluminum or carbon steel angles, several key differences become apparent. One significant advantage of stainless steel angles is their exceptional resistance to corrosion. This property makes stainless steel angles ideal for applications that involve exposure to moisture, chemicals, or other corrosive elements. Unlike aluminum angles, which may corrode or develop oxidation over time, stainless steel angles maintain their integrity and appearance even in demanding environments. Furthermore, stainless steel angles exhibit remarkable strength and durability. Compared to aluminum angles, stainless steel angles have a higher tensile strength, allowing them to withstand heavier loads and more rigorous conditions. This strength also translates into excellent structural stability, making stainless steel angles a reliable choice for construction and engineering projects. In terms of aesthetics, stainless steel angles offer a sleek and modern appearance. They can be easily polished or brushed to achieve a desired finish, adding an attractive and professional touch to architectural designs or interior applications. Conversely, aluminum angles may have a less refined appearance and are often used in applications where weight reduction is a priority. Although stainless steel angles tend to be more expensive than aluminum angles, they provide a longer service life and reduced maintenance costs due to their corrosion-resistant properties. Additionally, stainless steel angles are recyclable, making them an environmentally friendly choice. In summary, stainless steel angles surpass other types of angles in terms of corrosion resistance, strength, durability, and aesthetic appeal. While aluminum angles may be lighter and more cost-effective, stainless steel angles offer unmatched performance and reliability, making them the preferred choice for a wide range of applications.

- Q: Can stainless steel angles be used in automotive manufacturing?

- Yes, stainless steel angles can be used in automotive manufacturing. Stainless steel is a durable and corrosion-resistant material, making it suitable for various automotive applications. Stainless steel angles can be used for structural components, brackets, supports, and reinforcements in vehicles. They provide strength, stability, and longevity, making them an excellent choice for automotive manufacturing where high performance and reliability are essential. Additionally, stainless steel angles can withstand harsh environmental conditions, such as exposure to moisture, chemicals, and extreme temperatures, which are common in automotive applications.

- Q: What is the hardness of stainless steel angles?

- The hardness of stainless steel angles can vary depending on the specific grade of stainless steel used. Stainless steel is generally known for its high hardness, strength, and durability, which makes it suitable for various applications. The hardness of stainless steel is typically measured using the Rockwell hardness scale, and the specific value can range from relatively soft to very hard. It is important to note that the hardness of stainless steel can also be influenced by factors such as the heat treatment process, the composition of alloying elements, and the manufacturing methods. Therefore, it is recommended to consult the material specifications or consult with a supplier or manufacturer to determine the exact hardness of stainless steel angles for a particular grade or alloy.

- Q: What are the different types of corrosion that stainless steel angles can resist?

- Stainless steel angles can resist various types of corrosion, including general corrosion, pitting corrosion, crevice corrosion, intergranular corrosion, and stress corrosion cracking.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2010 |

| Annual Output Value | above US$16 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 30000 square meter |

| No. of Production Lines | above 7 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for 304 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords