Stainless Steel Angles with High Quatity Grade: SS200,300,400 Series

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

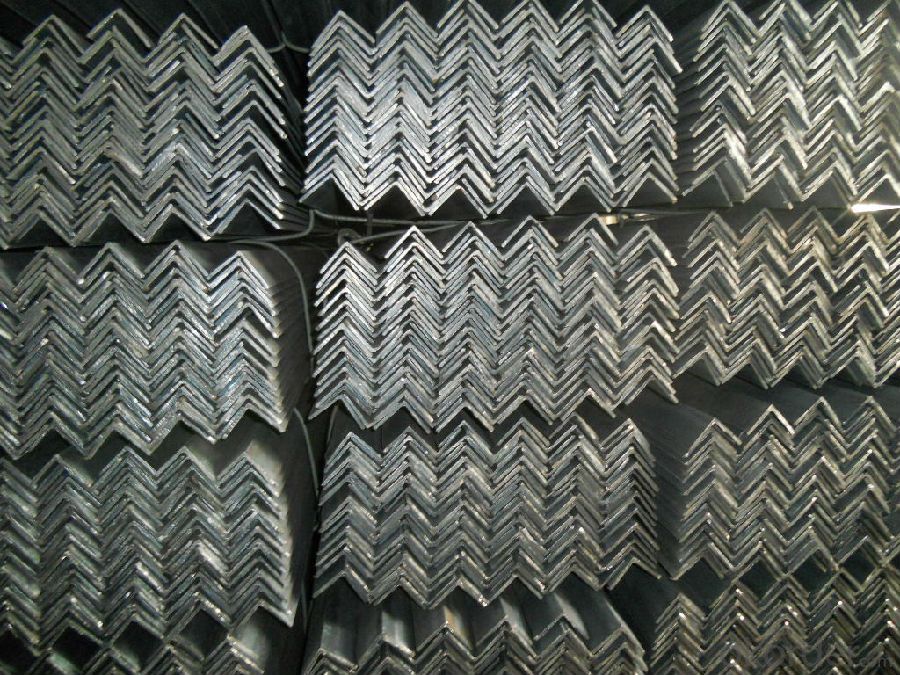

1. Structure of Angle Steel Description

Angle steel has equal angle, unequal angle. Standards: GB,ASTM,BS,AISI,DIN,JIS Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400; SS540.

Grade: SS200,300,400 series

Size: 25×25×3 mm-100×100×10mm

Process: HRAP

Length: 2-6m

Shape: Equal

Delivery: within 20 days

MOQ: 1 ton

Certificate: ISO 9001:2008, SGS

Package:Standard Export Packing, or put into wooden boxes according to your requirement

Application: Construction, Marine, Industry and so on

Name | Stainless Steel Angles | ||||||

Standard | ASTM A554, A312, A249, A269 and A270 | ||||||

Material Grade | 304,316,201,202, 316L,430 | ||||||

Length | 6m or as customers' request | ||||||

Tolerance | a) thickness: +/-0. 15mm | ||||||

b) Length:+/-4. 5mm - 0mm | |||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

Application | Decoration construction, upholstery, industry instruments | ||||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

Chemical Composition of Material | Composition Material | 201 | 202 | 304 | 316L | 430 | |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | ||

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ||

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | ||

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | ||

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | ||

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | ||

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | |||

Mo | 2.0-3.0 | ||||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316L | ||

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | |||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | |||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | |||

Hardness (HV) | <253< p=""> | <253< p=""> | <200< p=""> | <200< p=""> | |||

2.Main Features of angle steel

Broad-spectrum

High quantity

High strength

3.Usage & Applications of High Quatity Grade: SS200,300,400 Series Stainless Steel Angles

Trusses

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

4.Packaging & Delivery of GB Q235 Angle Steel

Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

- Q: How do steel angles contribute to the overall stability of a building?

- Steel angles are an essential component of the overall stability of a building. They provide structural support and enhance the load-bearing capacity of the building framework. The angle shape of steel angles allows them to efficiently distribute and transfer the loads imposed on the structure, such as the weight of the floors, walls, and the roof, to the foundation. One of the key contributions of steel angles to the stability of a building is their ability to resist bending and buckling forces. The L-shaped design of steel angles helps to prevent the structural members from collapsing or deforming under heavy loads or external pressures. This resistance to bending and buckling ensures that the building remains structurally sound and stable, even in adverse conditions such as earthquakes or strong winds. Furthermore, steel angles are often used as bracing elements to provide lateral stability to the building. They are strategically placed in areas that require reinforcement against horizontal forces, such as wind or seismic activity. By connecting different structural components, steel angles help to distribute these lateral forces throughout the building, preventing excessive movement or deformation and maintaining the overall stability of the structure. In addition to their role in load-bearing and bracing, steel angles also contribute to the overall stability of a building through their durability and resistance to corrosion. Steel angles are typically made from high-strength steel, which offers excellent structural integrity and long-term reliability. This durability ensures that the building can withstand the test of time and remain stable throughout its lifespan. Overall, steel angles play a crucial role in enhancing the overall stability of a building. Their ability to resist bending and buckling forces, provide lateral stability, and their durability make them an integral part of the building's structural system. By effectively distributing and transferring loads, steel angles ensure that the building remains safe, secure, and stable, ensuring the well-being of its occupants and the longevity of the structure.

- Q: Are steel angles susceptible to rusting?

- Rusting is possible for steel angles. Steel, which consists mostly of iron, reacts chemically with moisture and oxygen. This reaction is called oxidation and leads to the production of iron oxide, commonly known as rust. The speed of rusting can be affected by multiple factors, including the steel's quality, the presence of protective coatings, exposure to corrosive substances, and the level of humidity. Consequently, if steel angles are not appropriately safeguarded or maintained, they will gradually rust. To prevent or reduce the rusting process and prolong the lifespan of steel angles, it is advisable to regularly inspect, clean, and apply protective coatings.

- Q: Are there any environmental concerns associated with steel angles?

- Yes, there are several environmental concerns associated with steel angles. One of the main concerns is the production process of steel angles, which involves the extraction of iron ore, coal mining for coke production, and the emission of greenhouse gases during the steelmaking process. These activities contribute to deforestation, air pollution, and climate change. Additionally, the disposal of steel angles at the end of their life cycle can be problematic. Steel is not biodegradable and can take hundreds of years to decompose in landfills. Improper disposal of steel angles can lead to soil and water contamination, posing a risk to ecosystems and human health. Furthermore, the transportation of steel angles from production facilities to construction sites can contribute to carbon emissions and air pollution. The energy required for transportation increases the overall environmental impact of steel angles. To mitigate these environmental concerns, there are several strategies that can be adopted. Firstly, using recycled steel instead of virgin steel can significantly reduce the environmental footprint of steel angles. Additionally, implementing energy-efficient technologies in the steel production process can help minimize greenhouse gas emissions. Finally, responsible disposal and recycling of steel angles at the end of their life cycle can help reduce the environmental impact.

- Q: How do steel angles perform in extreme weather conditions?

- Steel angles have been specifically engineered to possess a remarkable level of durability and resistance towards severe weather conditions. Due to their exceptional strength and ability to endure harsh environments, they are commonly employed in construction and structural applications. When confronted with extreme weather events such as hurricanes, heavy snowfall, or strong winds, steel angles offer exceptional protection against these elements. The superior tensile strength of steel angles plays a pivotal role in their performance during extreme weather conditions. Their capacity to withstand significant loads and forces without distorting or fracturing makes them an ideal choice for enduring severe weather events. Moreover, steel angles are well-regarded for their outstanding resistance towards corrosion, a crucial attribute in areas characterized by high humidity, saltwater, or acidic surroundings. Another noteworthy aspect of steel angles is their remarkable versatility, as they can be easily fabricated and tailored to meet the specific requirements of a project. This adaptability ensures their suitability for a wide array of applications, including buildings, bridges, towers, and other structures that are exposed to extreme weather conditions. Furthermore, steel angles can be coated or treated to further enhance their resistance towards adverse weather conditions. For instance, the application of a galvanized coating can furnish additional protection against rust and corrosion, thereby prolonging the lifespan of the steel angles, even under the harshest weather conditions. In conclusion, steel angles have been meticulously designed to deliver exceptional performance in extreme weather conditions. Their remarkable tensile strength, corrosion resistance, and versatility establish them as a dependable choice for structures necessitating the ability to withstand hurricanes, heavy snowfall, strong winds, and other challenging weather events.

- Q: What is the maximum spacing for steel angles in a support structure?

- The maximum spacing for steel angles in a support structure depends on various factors such as the load requirements, material strength, and design specifications. However, it is generally recommended to consult with a structural engineer or refer to relevant building codes and standards to determine the appropriate maximum spacing for steel angles in a specific support structure.

- Q: Where does channel steel use more? Where does angle iron use more?

- Hot rolled stainless steel ordinary channel (GB707-88) main use: ordinary channel steel, mainly used for building structures, vehicle manufacturing and other industrial structures, often with the use of i-beam.

- Q: Can steel angles be painted?

- Yes, steel angles can be painted. The steel angles need to be properly cleaned, primed, and then painted using a suitable paint for metal surfaces.

- Q: What is the tensile strength of steel angles?

- The tensile strength of steel angles can vary depending on the specific grade of steel and the manufacturing process used. However, generally speaking, steel angles have a high tensile strength. Common grades of steel used for angles, such as A36, have a tensile strength of around 58,000-80,000 psi (pound-force per square inch). However, higher strength steel grades, such as A572 or A588, can have tensile strengths exceeding 100,000 psi. It is important to consult the specific grade and manufacturer's specifications to determine the exact tensile strength of steel angles in a given application.

- Q: What do you mean by "corner steel plate pull knot"?

- The angle iron can be made up of different force components according to the different structure, and can also be used as the connecting piece between the components. Widely used in a variety of architectural and engineering structures, such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reaction tower, container frame and warehouse.

- Q: What are the different types of steel coatings available for angles?

- There are several different types of steel coatings available for angles, each with its own unique characteristics and benefits. Some of the most common types include: 1. Galvanized coating: This is one of the most popular and widely used types of steel coating for angles. Galvanization involves applying a layer of zinc to the surface of the steel, providing excellent corrosion resistance. Galvanized angles are commonly used in outdoor applications or in environments where moisture and humidity are present. 2. Powder coating: Powder coating is a type of dry finishing process that involves applying a fine powder to the surface of the steel angles. The powder is electrostatically charged and adheres to the metal, creating a smooth, durable, and attractive finish. Powder coating provides excellent resistance to scratches, chipping, and fading, making it a popular choice for decorative or architectural applications. 3. Epoxy coating: Epoxy coatings are a type of thermosetting polymer that is applied to the surface of the steel angles. These coatings provide exceptional resistance to chemicals, corrosion, and abrasion, making them suitable for harsh and demanding environments. Epoxy-coated angles are commonly used in industrial settings, such as chemical plants or wastewater treatment facilities. 4. Paint coating: Paint coatings are a traditional and cost-effective option for steel angles. They are typically applied as a liquid and can be customized in terms of color and finish. While paint coatings provide some level of protection against corrosion, they may not be as durable or long-lasting as other types of coatings. However, they can still be suitable for indoor or low-corrosion applications. 5. Organic coating: Organic coatings, such as polyurethane or polyester, are often used to provide a decorative or protective layer to steel angles. These coatings offer excellent resistance to UV radiation, weathering, and fading, making them suitable for outdoor applications. Organic-coated angles can be found in architectural, construction, or infrastructure projects. It's important to consider the specific requirements of your application when choosing a steel coating for angles. Factors such as environmental conditions, aesthetic preferences, and durability needs should all be taken into account to ensure the proper selection of the coating that best suits your project.

Send your message to us

Stainless Steel Angles with High Quatity Grade: SS200,300,400 Series

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords