Stainless Steel Angles SS200,300,400 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

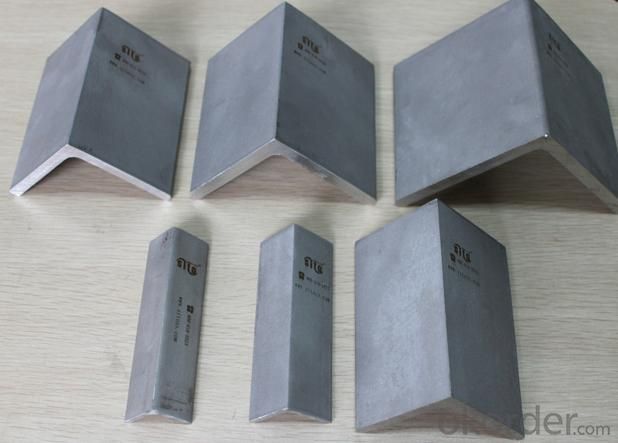

Stainless Steel Angles

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your

requirement

10. Application: Construction, Marine, Industry and so on

Name | Stainless Steel Angles | ||||||

Standard | ASTM A554, A312, A249, A269 and A270 | ||||||

Material Grade | 304,316,201,202, 316L,430 | ||||||

Length | 6m or as customers' request | ||||||

Tolerance | a) thickness: +/-0. 15mm | ||||||

| |||||||

b) Length:+/-4. 5mm - 0mm | |||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

Application | Decoration construction, upholstery, industry instruments | ||||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

Chemical Composition of Material |

Composition

Material | 201 | 202 | 304 | 316L | 430 | |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | ||

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ||

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | ||

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | ||

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | ||

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | ||

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 |

| ||

Mo |

|

|

| 2.0-3.0 |

| ||

Mechanical Property | Material Item | 201 | 202 | 304 | 316L | ||

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | |||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | |||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | |||

Hardness (HV) | <253 | <253 | <200 | <200 | |||

- Q: Can stainless steel angles be used in the production of outdoor fitness equipment?

- Stainless steel angles have the capability to be utilized in the manufacturing process of outdoor fitness equipment. Due to its exceptional durability and resistance to corrosion, stainless steel is an ideal material for outdoor applications where the equipment is subjected to diverse weather conditions. The inclusion of stainless steel angles guarantees structural reinforcement and stability, ultimately resulting in reliable and enduring performance. Moreover, the versatility of stainless steel angles enables the creation of intricate and personalized designs through easy welding techniques. In conclusion, the incorporation of stainless steel angles guarantees the equipment's durability, safety, and aesthetic appeal in outdoor surroundings.

- Q: What are the different types of stainless steel angles connections used in architecture?

- There are several different types of stainless steel angle connections that are commonly used in architecture. Some of the most popular ones include: 1. Welded connections: Welding is a common method used to join stainless steel angles in architecture. This involves melting the edges of the angles and fusing them together to create a strong and durable connection. Welded connections are often used in structural applications where strength is a primary concern. 2. Bolted connections: Bolted connections involve using stainless steel bolts to fasten the angles together. This method allows for easy disassembly and reassembly, making it ideal for situations where flexibility and modularity are important. Bolted connections are commonly used in architectural applications such as curtain walls and steel frames. 3. Adhesive connections: Adhesive connections involve using specialized adhesives to bond stainless steel angles together. This method is often used in situations where aesthetics are a priority, as it eliminates the need for visible fasteners. Adhesive connections are commonly used in architectural applications such as cladding and interior design. 4. Mechanical connections: Mechanical connections involve using mechanical devices such as brackets, clips, or brackets to join stainless steel angles together. These devices provide a secure and reliable connection while also allowing for adjustability and flexibility. Mechanical connections are commonly used in architectural applications such as handrails, balustrades, and canopies. 5. Combination connections: In some cases, a combination of different connection methods may be used to join stainless steel angles together. For example, a welded connection may be reinforced with bolts or adhesive for added strength and stability. Combination connections are often used in complex architectural structures that require multiple layers of reinforcement. Overall, the choice of stainless steel angle connection in architecture depends on factors such as the specific application, design requirements, and desired aesthetics. Architects and engineers carefully consider these factors to select the most suitable connection method for each project.

- Q: How do you calculate the bending stress of a stainless steel angle?

- In order to determine the bending stress of a stainless steel angle, one must take into account the properties of the angle and the applied load. The first step is to calculate the moment of inertia (I) of the angle section. This value represents the angle's resistance to bending. The moment of inertia can be determined using the formula for the moment of inertia of a rectangular section: I = (b * h^3) / 12. Here, b refers to the width of the angle and h represents the height. Following that, the maximum bending moment (M) that the angle will experience needs to be calculated. This is typically achieved by analyzing the applied load and its distribution along the length of the angle. The bending moment can be found by multiplying the applied load by the distance from the point of load application to the point where the bending stress is being assessed. Lastly, the bending stress (σ) can be calculated using the formula σ = (M * c) / I. In this equation, c denotes the distance from the neutral axis of the angle to the point where the bending stress is being calculated. The neutral axis is the line within the angle's cross-section where no stress or strain occurs when subjected to bending. It is essential to bear in mind that the aforementioned calculations are simplified and assume that the stainless steel angle behaves linearly and elastically. In reality, stainless steel may exhibit some non-linear behavior. Therefore, it is advisable to consult relevant design codes or reference materials for more precise calculations and considerations.

- Q: How do stainless steel angles contribute to the overall strength of a product?

- Stainless steel angles play a crucial role in enhancing the overall strength of a product due to their unique properties and structural design. Firstly, stainless steel is known for its exceptional strength and durability, making it an ideal material choice for various applications. The angles are typically made from high-quality stainless steel, which offers excellent resistance to corrosion, heat, and impact. The angled shape of stainless steel angles provides structural support and reinforcement to the product, particularly in load-bearing applications. By incorporating angles into the design, the product's overall strength is significantly enhanced as they help distribute and bear the weight or stress evenly across the structure. This prevents any concentration of forces and minimizes the risk of deformations or failures. Moreover, stainless steel angles offer additional stability and rigidity to the product, especially when used in conjunction with other components or fasteners. Their angled design creates a triangular structure, which is known for its stability and ability to resist bending or twisting forces. This ensures that the product can withstand heavy loads, vibrations, or external impacts without compromising its integrity. Furthermore, stainless steel angles contribute to the overall strength of a product by improving its resistance to deflection or distortion. The angles act as braces or supports, preventing any undesired flexing or bending of the structure, thus maintaining its shape and stability over time. In summary, stainless steel angles are essential components that significantly contribute to the overall strength of a product. With their high strength, corrosion resistance, and angled design, they provide structural support, reinforcement, stability, and rigidity, ultimately enhancing the product's durability and ability to withstand various external forces or loads.

- Q: Can stainless steel angle be used in outdoor applications?

- Yes, stainless steel angle can be used in outdoor applications. Stainless steel is known for its excellent resistance to corrosion, making it a suitable choice for outdoor environments where it may be exposed to moisture, humidity, and other weather conditions. Stainless steel angle is commonly used in outdoor applications such as handrails, support brackets, frames, and construction projects. It offers durability, strength, and a sleek appearance, making it a popular choice for outdoor structures. However, it is important to ensure that the stainless steel used is of high quality and has the appropriate grade and finish for the specific outdoor application to maximize its corrosion resistance and longevity.

- Q: Can stainless steel angles be used in the construction of support structures?

- Yes, stainless steel angles can be used in the construction of support structures. Stainless steel is known for its strength, durability, and corrosion resistance, making it an ideal material for support structures that need to withstand heavy loads. Stainless steel angles are particularly useful in providing structural support and stability as they have a right angle shape that can be easily bolted or welded to other components. They can be used in various applications such as building frames, bridges, platforms, and equipment supports. Additionally, stainless steel angles have a sleek and modern appearance, making them suitable for architectural and aesthetic purposes as well. Overall, stainless steel angles are a reliable choice for constructing support structures due to their strength, longevity, and versatility.

- Q: Can stainless steel angles be used in electrical applications?

- Yes, stainless steel angles can be used in electrical applications. Stainless steel is an excellent material choice for electrical applications due to its high corrosion resistance, durability, and electrical conductivity. Stainless steel angles can be used for mounting electrical components, providing support and stability, and ensuring proper grounding in electrical systems.

- Q: Can stainless steel angles be used in the construction of storage tanks?

- Yes, stainless steel angles can be used in the construction of storage tanks. Stainless steel angles are a versatile and durable material that is highly resistant to corrosion and can withstand high temperatures and pressure. They are commonly used in various industries, including storage tank construction, due to their excellent mechanical properties and ability to withstand harsh environmental conditions. Stainless steel angles provide structural support and stability to the storage tanks, ensuring their integrity and longevity. Additionally, stainless steel angles can be easily fabricated and welded, making them suitable for constructing storage tanks of different sizes and shapes.

- Q: What are the temperature limits for stainless steel angles?

- The temperature limits for stainless steel angles depend on the specific grade of stainless steel being used. However, in general, most stainless steel alloys can withstand temperatures ranging from -150°C (-238°F) to 815°C (1499°F) without significant loss of strength or corrosion resistance.

- Q: How do stainless steel angles compare to other materials?

- Stainless steel angles are highly advantageous compared to other materials due to their exceptional corrosion resistance, durability, and strength. They offer superior stability and longevity, making them ideal for various applications in construction, manufacturing, and engineering industries. Additionally, stainless steel angles have an attractive aesthetic appearance and require minimal maintenance, making them a cost-effective choice in the long run.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2010 |

| Annual Output Value | above US$16 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 30000 square meter |

| No. of Production Lines | above 7 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Angles SS200,300,400 Series

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords