cold roll forming steel channel for construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

cold roll forming steel channel for construction

Products Information

| 1.Product Size | Size : 5#--40# | ||||

| 2.Product length | Lengths : 6m--12m | ||||

| 3.Standard | Standard : GB, ASTM, JIS, DIN | ||||

| 4.Grade | Grades : Q235B, Q345B, SS400 | ||||

| 5.Application | Used or building structures, vehicle | ||||

| manufacturing and other industrial structures | |||||

| 6.Features | Can produce special specification products | ||||

| as per our customers' requirement | |||||

| 7.Delivery Time | 15-30 days after recieve the LC or pre-paid | ||||

| 8.Detail Package | Bundles, seaworthy wooden cases with or without | ||||

| edge protector, steel hoop and seals, or as per | |||||

| customers' requirements | |||||

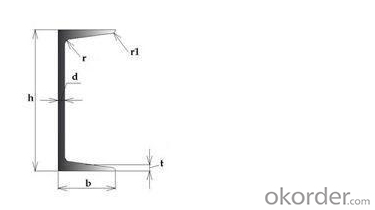

Drawing and Detail DATA (help to know more information)

Specification | h | b | d | t | Cm2 | (kg/m) |

5 | 50 | 37 | 4.5 | 7 | 6.93 | 5.44 |

6.3 | 63 | 40 | 4.8 | 7.5 | 8.45 | 6.63 |

8 | 80 | 43 | 5 | 8 | 10.24 | 8.04 |

10 | 100 | 48 | 5.3 | 8.5 | 12.74 | 10 |

12.6 | 126 | 53 | 5.5 | 9 | 15.69 | 12.37 |

14a | 140 | 58 | 6 | 9.5 | 18.51 | 14.53 |

14b | 140 | 60 | 8 | 9.5 | 21.31 | 16.73 |

16a | 160 | 63 | 6.5 | 10 | 21.95 | 17.23 |

16 | 160 | 65 | 8.5 | 10 | 25.15 | 19.74 |

18a | 180 | 68 | 7 | 10.5 | 25.69 | 20.17 |

18 | 180 | 70 | 9 | 10.5 | 29.29 | 22.99 |

Other Steel Bar Specification:

1.Square bar:Size: 4mm*4mm~100mm*100mm

2.Round Bar:Diameter: 3mm~800mm

3.Angel Bar:Size: 3mm*20mm*20mm~12mm*100mm*100mm

4.Flat bar:Thickness: 2mm~100mm,Width: 10mm~500mm,

5.Hexagonal :Size: 2mm~100mm

- Q: What is the maximum length of a stainless steel angle?

- The maximum length of a stainless steel angle can vary depending on several factors such as the specific manufacturer, the available raw materials, and the intended use of the angle. However, in general, stainless steel angles are commonly available in lengths ranging from 6 feet (1.83 meters) to 20 feet (6.10 meters). Some manufacturers may offer longer lengths on a custom order basis. It is always recommended to consult with the specific manufacturer or supplier to determine the maximum length options available for the desired stainless steel angle.

- Q: How do you calculate the moment of resistance for an unequal leg stainless steel angle?

- In order to determine the moment of resistance for an unequal leg stainless steel angle, one must take into account the properties of the angle section and utilize the appropriate formulas. The moment of resistance indicates the angle's ability to withstand bending and is determined by its geometry and material properties. To calculate the moment of resistance, follow these steps: 1. Measure the dimensions of the angle: Obtain the lengths of each leg and the thickness of the angle. These measurements will be necessary for further calculations. 2. Calculate the moment of inertia: The moment of inertia is a geometric characteristic that describes the distribution of mass around an axis. For an unequal leg angle, it is necessary to calculate the moment of inertia for both the x-axis and y-axis. The specific formulas for calculating the moment of inertia can be found in engineering handbooks or online resources. 3. Determine the yield strength of the stainless steel: The yield strength is a material property that represents the maximum stress the stainless steel can endure without experiencing permanent deformation. This information can typically be obtained from material specifications or testing. 4. Utilize the moment of resistance formula: The moment of resistance (M) can be determined using the equation M = fy * Z, where fy represents the yield strength of the stainless steel and Z denotes the plastic section modulus. The plastic section modulus is obtained by dividing the moment of inertia by the distance from the neutral axis to the outermost fiber of the angle section. 5. Insert the values into the equation: Substitute the yield strength and the plastic section modulus into the equation to calculate the moment of resistance for the unequal leg stainless steel angle. Please note that these calculations are based on simplified assumptions and may not account for all potential factors. For critical applications or specific design requirements, it is advisable to consult a qualified structural engineer or refer to applicable design codes and standards.

- Q: Are stainless steel angles resistant to oxidation?

- Yes, stainless steel angles are highly resistant to oxidation. The main reason behind this resistance is the presence of chromium in the steel composition. Chromium forms a thin, protective layer on the surface of the stainless steel, called a passive film. This film acts as a barrier against oxygen and moisture, preventing them from reaching the underlying metal. As a result, stainless steel angles are highly resistant to rust and corrosion, making them suitable for a wide range of applications, including outdoor and marine environments. Additionally, stainless steel angles can also withstand high temperatures and harsh chemicals, further enhancing their resistance to oxidation.

- Q: How do stainless steel angles contribute to sustainability?

- There are various ways in which stainless steel angles contribute to sustainability. To begin with, stainless steel is an incredibly durable material that has a long lifespan. Unlike other materials, stainless steel angles do not easily degrade or corrode, reducing the likelihood of them ending up in landfills. This extended lifespan decreases the need for frequent replacements and helps conserve resources. Moreover, stainless steel is a recyclable material. Once stainless steel angles reach the end of their life cycle, they can be easily recycled and transformed into new products. Recycling stainless steel requires much less energy compared to producing it from raw materials, resulting in lower carbon emissions and resource consumption. Additionally, stainless steel is renowned for its resistance to rust and corrosion. This characteristic eliminates the necessity for protective coatings or treatments, lowering the use of harmful chemicals and minimizing the environmental impact during the manufacturing process. Another aspect that contributes to sustainability is the fact that stainless steel is non-toxic and hygienic. This makes it an ideal choice for numerous applications, particularly in the food and healthcare industries where cleanliness and safety are crucial. By utilizing stainless steel angles in such applications, we can ensure that they are free from contaminants and harmful substances, thus promoting a healthier environment. Furthermore, stainless steel is an excellent option for outdoor applications due to its ability to withstand extreme weather conditions and UV radiation. This quality allows stainless steel angles to endure exposure to sunlight, rain, and other environmental factors without deteriorating. As a result, this reduces the need for frequent maintenance or replacements, leading to cost savings and a smaller environmental footprint. In summary, stainless steel angles contribute to sustainability through their durability, recyclability, resistance to corrosion, non-toxicity, and suitability for outdoor applications. By opting for stainless steel angles, we can support a more sustainable future by reducing waste, conserving resources, minimizing environmental impacts, and ensuring the safety and hygiene of various industries.

- Q: What are the fire resistance properties of stainless steel angle?

- Stainless steel angle has excellent fire resistance properties due to its high melting point and low thermal conductivity. It is able to withstand high temperatures without losing its structural integrity, making it a reliable choice for fire-resistant applications.

- Q: Can stainless steel angles be threaded?

- Yes, stainless steel angles can be threaded. Stainless steel is a versatile material that can be easily machined and threaded. The threading process involves cutting grooves on the surface of the stainless steel angle, allowing it to be screwed or bolted into place. Threaded stainless steel angles are commonly used in various applications, including construction, manufacturing, and structural engineering. It is important to note that the threading process should be done with precision and care to ensure proper fit and functionality.

- Q: What are the fire-resistant properties of stainless steel angles?

- Due to their composition and structural characteristics, stainless steel angles offer excellent fire-resistant properties. Stainless steel, primarily composed of iron, chromium, and elements like nickel and molybdenum, forms an alloy that creates a passive oxide layer on the surface. This layer acts as a protective barrier against corrosion and heat. When faced with fire, stainless steel angles demonstrate impressive resistance to oxidation and maintain their structural integrity. With a high melting point of around 1400-1450 degrees Celsius, they can withstand extreme temperatures without bending or weakening. As a result, stainless steel angles are highly suitable for fire-prone environments such as industrial facilities, construction sites, and residential buildings. Additionally, stainless steel angles possess a low thermal conductivity, meaning they do not readily conduct heat like materials such as aluminum or carbon steel. This property effectively prevents the spread of heat and flames, making stainless steel angles an effective fire barrier. Another benefit of using stainless steel angles in fire-resistant applications is their resistance to thermal expansion. Even when exposed to high temperatures, stainless steel angles experience minimal expansion and contraction, ensuring their structural stability in extreme thermal conditions. To summarize, stainless steel angles offer exceptional fire-resistant properties due to their high melting point, resistance to oxidation, low thermal conductivity, and minimal thermal expansion. These qualities make stainless steel angles a reliable choice for various fire-related applications where safety and durability are of utmost importance.

- Q: What are the different corrosion resistance properties of stainless steel angles?

- Stainless steel angles have excellent corrosion resistance properties due to the presence of chromium in their composition. The chromium forms a protective oxide layer on the surface, which prevents further corrosion. Additionally, stainless steel angles can have varying levels of nickel and molybdenum, which enhance their resistance to specific types of corrosion, such as pitting, crevice, and intergranular corrosion. Overall, stainless steel angles offer a high level of corrosion resistance, making them suitable for various applications in corrosive environments.

- Q: What are the different types of edge finishes for rounded corner stainless steel angles?

- There are several different types of edge finishes available for rounded corner stainless steel angles. One common type of edge finish is a polished finish. This involves buffing the edges of the stainless steel angle to create a smooth and shiny surface. This type of finish is often used for aesthetic purposes, as it enhances the overall appearance of the angle. Another popular edge finish is a brushed finish. This is achieved by using a fine abrasive material to create a pattern of fine lines on the surface of the stainless steel angle. Brushed finishes are commonly used in applications where a more matte appearance is desired. A third type of edge finish is a bead blasted finish. This involves using small glass beads to create a uniform, matte texture on the surface of the stainless steel angle. Bead blasted finishes are often chosen for their durability and resistance to scratches and fingerprints. Additionally, there are options for custom edge finishes, such as chamfered or rounded edges. These types of edge finishes can be requested to meet specific design or safety requirements. Overall, the choice of edge finish for rounded corner stainless steel angles will depend on the desired aesthetic, functionality, and application of the angle. It is important to consider factors such as durability, maintenance, and the environment in which the angle will be used when selecting the appropriate edge finish.

- Q: What are the different lengths of stainless steel angles available?

- Stainless steel angles are available in various lengths to suit different applications and requirements. The lengths can vary depending on the manufacturer and the specific product line. Common lengths for stainless steel angles range from 6 feet (72 inches) to 20 feet (240 inches), with increments of 1 foot or 2 feet. However, it is important to note that custom lengths can also be fabricated based on individual project needs. Stainless steel angles are versatile structural components used in construction, manufacturing, and other industries, offering strength, durability, and corrosion resistance.

Send your message to us

cold roll forming steel channel for construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords