Best Quality for 201 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

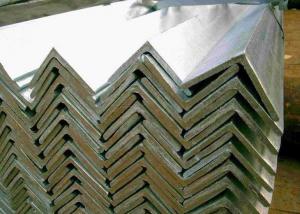

Stainless Steel Angles

General Information of Stainless Steel Angles

1. Grade: SS200, 300,400 series

2. Size: 25×25×3 mm-100×100×10mm

3. Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package: Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry and so on.

Specification of Stainless Steel Angles

Name | Stainless Steel Angles | |||||

Standard | ASTM A554, A312, A249, A269 and A270 | |||||

Material Grade | 304,316,201,202, 316L,430 | |||||

Length | 6m or as customers' request | |||||

Tolerance | a) Thickness: +/-0. 15mm | |||||

b) Length: +/-4. 5mm - 0mm | ||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | |||||

Application | Decoration construction, upholstery, industry instruments | |||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | |||||

Chemical Composition of Material | Composition Material | 201 | 202 | 304 | 316 | 430 |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | |

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | |

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | ||

Mo | 2.0-3.0 | |||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316 | |

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

Hardness (HV) | <253 | <253 | <200 | <200 | ||

- Q: How do you determine the torsional strength of a stainless steel angle?

- To determine the torsional strength of a stainless steel angle, several factors need to be considered. Firstly, it is important to understand that torsional strength refers to the ability of a material to resist twisting or rotational forces. In the case of a stainless steel angle, torsional strength is a measure of its resistance to deformation or failure when subjected to torsional loads. One way to determine the torsional strength is by conducting a torsion test. This test involves applying a twisting force to the stainless steel angle until it reaches its maximum torsional strength or failure point. The test is typically performed using a torsion testing machine that applies a controlled torque to the angle. During the torsion test, various parameters are measured, including the angle of twist, torque, and torsional stress. These parameters can be used to calculate the torsional strength of the stainless steel angle. The torsional strength is usually expressed in terms of torque per unit length or torque per unit area. It is worth noting that the torsional strength of a stainless steel angle can depend on several factors, such as the alloy composition, heat treatment, and manufacturing process. Therefore, it is essential to ensure that the test specimens are representative of the actual angle being used in the application. In addition to torsion testing, other methods such as finite element analysis (FEA) can also be employed to determine the torsional strength of a stainless steel angle. FEA uses computer modeling and simulation techniques to analyze the behavior of the angle under torsional loads. This approach allows for a more detailed understanding of the angle's torsional strength and can help optimize its design for specific applications. In conclusion, determining the torsional strength of a stainless steel angle involves conducting torsion tests or utilizing computational methods such as FEA. These methods provide valuable information about the angle's resistance to twisting forces and help ensure its suitability for various engineering applications.

- Q: What are the different types of connections used with stainless steel angles in construction?

- There are several different types of connections that can be used with stainless steel angles in construction. Some of the most common types include: 1. Welded connections: This is one of the most common methods of connecting stainless steel angles. It involves welding the angles together using a welding process such as MIG or TIG welding. Welded connections provide a strong and durable connection that can withstand heavy loads and stresses. 2. Bolted connections: Another common method is to use bolts to connect the stainless steel angles. This involves drilling holes through the angles and using bolts and nuts to secure them together. Bolted connections are easier to disassemble and modify, making them a popular choice for temporary structures or situations where adjustments may be needed. 3. Riveted connections: Riveting involves using rivets to join the stainless steel angles together. This method is commonly used in situations where welding or bolting may not be feasible, such as in areas with limited access or where heat distortion is a concern. Riveted connections provide a strong and reliable connection, but they can be time-consuming and require specialized tools. 4. Adhesive connections: Adhesive bonding is sometimes used to connect stainless steel angles in construction. This involves using high-strength adhesive or epoxy to bond the angles together. Adhesive connections can be a good option for situations where drilling or welding is not desired, or for joining dissimilar materials. However, they may not be as strong as other connection methods and may require regular maintenance and inspection. It is important to consider the specific requirements of the construction project and consult with a structural engineer or other qualified professionals to determine the most appropriate type of connection for stainless steel angles.

- Q: Are stainless steel angles resistant to hydrofluoric acid?

- Yes, stainless steel angles are generally resistant to hydrofluoric acid. Stainless steel is known for its high resistance to corrosion and can withstand exposure to a wide range of acids, including hydrofluoric acid. This resistance is due to the presence of chromium in stainless steel, which forms a protective oxide layer on the surface of the metal, preventing it from reacting with the acid. However, it is important to note that the resistance may vary depending on the specific grade and composition of stainless steel used.

- Q: Can stainless steel angles be used in high-temperature environments?

- Yes, stainless steel angles can be used in high-temperature environments. Stainless steel is known for its excellent heat resistance and can withstand high temperatures without losing its strength or corroding.

- Q: How do you calculate the section modulus for a stainless steel angle?

- To calculate the section modulus for a stainless steel angle, you need to determine the moment of inertia of the angle cross-section and divide it by the distance from the centroid to the outermost fibers. The formula for calculating the section modulus is Z = I/c, where Z is the section modulus, I is the moment of inertia, and c is the distance from the centroid to the outermost fibers.

- Q: Can stainless steel angles be used in outdoor applications?

- Certainly! Outdoor applications can indeed benefit from the use of stainless steel angles. With their exceptional resistance to corrosion and rust, stainless steel is an excellent choice of material for such purposes. It demonstrates remarkable endurance against moisture, rain, snow, and extreme temperatures, ensuring that it remains structurally sound and unaffected. In fact, stainless steel angles are frequently employed in outdoor construction undertakings like fences, handrails, supports, and frames, as they offer a combination of strength, durability, and an elegant aesthetic. This makes them a favored option for various outdoor uses.

- Q: Are stainless steel angles suitable for the production of bike racks?

- Yes, stainless steel angles are suitable for the production of bike racks. Stainless steel is known for its strength, durability, and corrosion resistance, making it an ideal material for outdoor applications like bike racks. The angled shape of stainless steel angles can provide stability and support for holding bicycles securely. Additionally, stainless steel's sleek and modern appearance adds aesthetic appeal to bike racks.

- Q: How do you calculate the bending moment of stainless steel angles?

- To calculate the bending moment of stainless steel angles, you need to consider the properties of the material, the geometry of the angle, and the applied load. First, you need to determine the moment of inertia (I) of the stainless steel angle. The moment of inertia measures the resistance of the angle to bending. The moment of inertia is specific to the shape of the angle and can be found in reference tables or calculated using mathematical formulas. Next, you need to determine the distance (d) from the neutral axis to the outermost fiber of the angle. This distance is known as the section modulus (Z), which represents the resistance of the angle to bending. The section modulus can be calculated using the formula Z = I / (d/2). Once you have the moment of inertia and section modulus, you can calculate the bending moment (M) by using the formula M = σ × Z, where σ represents the stress applied to the angle. The stress can be determined using the applied load (F) and the distance from the neutral axis to the point of interest (y). It is important to note that the bending moment calculation assumes that the stainless steel angle is subjected to pure bending, meaning the load is applied perpendicular to the angle's neutral axis. If the load is not applied in this manner, additional calculations may be required to account for the different load distribution. Overall, calculating the bending moment of stainless steel angles involves understanding the material properties, determining the moment of inertia and section modulus, and applying the appropriate formulas to calculate the bending moment based on the applied load.

- Q: What is the resistance to fatigue of stainless steel angles?

- The resistance to fatigue of stainless steel angles is generally considered to be high. Stainless steel is known for its exceptional strength, durability, and resistance to corrosion, making it an ideal material for various applications. When subjected to cyclic loading or repetitive stress, stainless steel angles have the ability to withstand fatigue and maintain their structural integrity over time. The fatigue resistance of stainless steel angles can be attributed to several factors. Firstly, stainless steel contains a high percentage of chromium, which forms a protective oxide layer on the surface, providing excellent corrosion resistance. This protective layer helps to prevent the initiation and propagation of cracks, reducing the likelihood of fatigue failure. Furthermore, stainless steel angles are often manufactured using specific heat treatment processes, such as annealing or cold working, which enhance their mechanical properties. These processes can increase the strength and hardness of the angles, improving their resistance to fatigue. It is important to note that the resistance to fatigue of stainless steel angles can vary depending on the specific grade of stainless steel used, as well as the design and manufacturing processes employed. Therefore, it is advisable to consult the relevant material specifications, industry standards, and engineering guidelines to ensure the appropriate selection and application of stainless steel angles for specific fatigue requirements.

- Q: Can stainless steel angles be used in storage tank manufacturing?

- Stainless steel angles are indeed applicable in the manufacturing of storage tanks. Due to its exceptional resistance to corrosion, durability, and strength, stainless steel is highly favored as a material for storage tanks. To reinforce the tank's structure and provide additional support and stability, stainless steel angles are frequently employed. These angles are typically joined together through welding or bolting, forming the tank's framework and ensuring its ability to endure internal pressure and external forces. Furthermore, the smooth and polished surface of stainless steel angles facilitates the cleaning and maintenance of the storage tank, which is particularly crucial in industries such as food and beverage, pharmaceuticals, and chemical storage. Consequently, stainless steel angles constitute a suitable choice for the manufacturing of storage tanks.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | China, East Asia, |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for 201 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords