Stainless Angle Steel Bar ASTM 316l with Customized Surface Treatment

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ASTM 316l Stainless Angle Steel Bar

Main Structure of Angle Steel Bar

1.Surface:Bright,Polished,Turn smooth(Peeled),Brush,Mill,Pickled

2.Length:3m, 6m,9m,12m

3.Use:These products are widely supplied to areas of machine-made industry,chemical industry,spin,shipping industry,architecture,food industry,household products etc

4 ISO9001:2008

Data Information of Angle Steel Bar

Standard | AISI, ASTM, BS, DIN, GB, JIS, etc |

Grade | Q195, Q215, Q235, Q345, SS400, A36, S235JR, ST37, etc |

Technical parameters:

1) Material: Q235B , Q 345B, SS400 ,SS540, S235JR ,ETC. | |||

| 2) Usage: structure construction and electronic tower building | |||

| 3) Weight tolarance: -4% TO -10% | |||

| 4) Size tolarance : | |||

| ANGLE STEEL SIstructural steel angleE TOLARANCE (MM) | |||

| SIstructural steel angleE cm | WIDTH b/mm | THICKNESS d/mm | LENGTH /m |

| 2-5.6 | +/-0.8 | +/-0.4 | 4-12 |

| 6.3-9 | +/-1.2 | +/-0.6 | 4-12 |

| 10-14 | +/-1.8 | +/-0.7 | 4-12 |

| 16-20 | +/-2.5 | +/-1.0 | 4-12 |

| 5) Payment terms: TT or LC | |||

| 6) Delivery date: within 30 days after receiving the LC or TT prepay | |||

| 7) Packing: Export package | |||

| 8) Inspection: accept third party inspection | |||

Specification of Angle Steel Bar

1.Square bar:Size: 4mm*4mm~100mm*100mm

2.Round Bar:Diameter: 3mm~800mm

3.Angel Bar:Size: 3mm*20mm*20mm~12mm*100mm*100mm

4.Flat bar:Thickness: 2mm~100mm,Width: 10mm~500mm,

5.Hexagonal :Size: 2mm~100mm

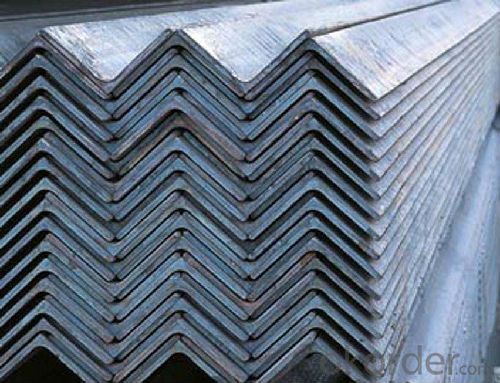

Picture

- Q: What is the maximum length of a stainless steel angle?

- The maximum length of a stainless steel angle can vary depending on several factors such as the specific manufacturer, the available raw materials, and the intended use of the angle. However, in general, stainless steel angles are commonly available in lengths ranging from 6 feet (1.83 meters) to 20 feet (6.10 meters). Some manufacturers may offer longer lengths on a custom order basis. It is always recommended to consult with the specific manufacturer or supplier to determine the maximum length options available for the desired stainless steel angle.

- Q: What is the bending radius for stainless steel angles?

- The bending radius for stainless steel angles can vary depending on the specific grade and thickness of the material. However, in general, stainless steel angles have a relatively small bending radius due to their high strength and rigidity. It is advisable to consult with a manufacturer or engineer to determine the specific bending radius for a particular stainless steel angle.

- Q: What are the different types of surface treatments for stainless steel angles?

- There are several different types of surface treatments available for stainless steel angles. 1. Passivation: This is a common treatment that involves the use of chemicals to remove any iron particles or contaminants from the surface of the stainless steel. It helps to improve the corrosion resistance of the material. 2. Pickling: Pickling involves the immersion of the stainless steel angles in a pickling solution, usually an acid, to remove any oxide scale or heat tint. This treatment helps to restore the stainless steel's corrosion resistance and enhances its appearance. 3. Electropolishing: This is an electrochemical process that removes a thin layer of material from the surface of the stainless steel angles. It helps to improve the surface finish, remove any surface irregularities, and enhance the corrosion resistance of the material. 4. Coating: Stainless steel angles can also be coated with various materials to provide an additional layer of protection. Common coatings include epoxy, powder coating, or paint. These coatings not only provide corrosion resistance but also improve the aesthetic appearance of the stainless steel angles. 5. Grinding and polishing: Grinding and polishing are mechanical treatments that can be used to enhance the surface finish of stainless steel angles. These processes help to remove any surface imperfections, scratches, or blemishes, resulting in a smooth and shiny surface. Each of these surface treatments offers unique benefits and is suitable for different applications. The choice of treatment depends on factors such as the desired appearance, corrosion resistance requirements, and the intended use of the stainless steel angles.

- Q: Are stainless steel angles resistant to high temperatures?

- Yes, stainless steel angles are generally resistant to high temperatures. Stainless steel is known for its ability to withstand high heat without losing its strength or becoming deformed. This is due to the presence of chromium in the steel, which forms a protective oxide layer that prevents corrosion and oxidation at elevated temperatures. Stainless steel angles are commonly used in applications where high temperatures are encountered, such as in industrial furnaces, heat exchangers, and power plants. However, the specific temperature range that stainless steel can withstand without any significant damage depends on the grade of stainless steel and the duration of exposure to high temperatures.

- Q: What are the different manufacturing standards for stainless steel angles?

- Stainless steel angles adhere to various manufacturing standards in order to meet specific requirements and quality standards. Some commonly utilized manufacturing standards for stainless steel angles include: 1. ASTM A276: This standard outlines the specifications for stainless steel angles in both hot-rolled and cold-finished conditions. It encompasses multiple grades of stainless steel and provides guidelines for chemical composition, mechanical properties, heat treatment, and tolerances. 2. EN 10056: As a European standard, this mandates the tolerances, dimensions, and sectional properties of stainless steel angles. It encompasses a wide range of dimensions and offers guidance for the production process, including rolling and heat treatment. 3. DIN 1028: This German standard specifies the dimensions, tolerances, and static values for hot-rolled stainless steel angles. It offers guidelines for the production process, including rolling and heat treatment, while ensuring the product adheres to specific quality requirements. 4. JIS G 4317: As a Japanese standard, this provides specifications for hot-formed stainless steel sections, including angles. It offers guidelines for the chemical composition, mechanical properties, and heat treatment of stainless steel angles. 5. GB/T 706-2008: This Chinese standard details the dimensions, shape, weight, and tolerances of hot-rolled stainless steel angles. It covers multiple grades of stainless steel and provides guidelines for the production process, including rolling and heat treatment. These manufacturing standards guarantee consistent production and ensure stainless steel angles meet the necessary specifications for diverse applications. Manufacturers, suppliers, and customers rely on these standards to ensure the quality and dependability of stainless steel angles in construction, architectural, and industrial settings.

- Q: What are the maximum load capacities of stainless steel angles?

- The maximum load capacities of stainless steel angles can vary depending on several factors, including the size, thickness, and grade of the angle. Stainless steel angles are generally recognized for their strength and ability to bear heavy loads. To determine the maximum load capacity, it is crucial to consider the specific requirements and specifications of the stainless steel angle being used. Factors such as the angle's length and width, the type of load (vertical or horizontal), the support structure, and the method of installation can all affect the load capacity. Stainless steel angles are typically designed to handle significant loads due to their durability and resistance to corrosion. However, it is important to consult with structural engineers or consult technical resources, such as load tables provided by stainless steel manufacturers or industry standards, to obtain accurate information on the maximum load capacities of specific stainless steel angles. By considering the necessary factors and employing proper engineering practices, the maximum load capacities of stainless steel angles can be determined and effectively utilized in various applications, including construction, manufacturing, and structural engineering.

- Q: How do stainless steel angles contribute to the durability of a structure?

- Stainless steel angles contribute to the durability of a structure by providing excellent corrosion resistance, high strength, and structural integrity. They are able to withstand harsh environmental conditions, such as exposure to moisture, chemicals, and extreme temperatures, without rusting or deteriorating. Additionally, stainless steel angles offer long-term stability, ensuring structural integrity and minimizing the need for maintenance or repairs.

- Q: Can stainless steel angles be bent or formed?

- Yes, stainless steel angles can be bent or formed, but the process may require specialized equipment and techniques due to the material's high strength and hardness. Stainless steel angles can be bent or formed using methods such as cold bending, heat bending, or hydraulic press bending. Cold bending is the most common method and involves using mechanical force to shape the angle without the need for heat. Heat bending involves heating the stainless steel angle to a specific temperature to make it more malleable for bending. Hydraulic press bending utilizes hydraulic force to bend the angle into the desired shape. Overall, while stainless steel angles can be bent or formed, it is important to ensure that the proper techniques and equipment are used to avoid damaging the material.

- Q: What is the difference between 304LN and 316LN stainless steel angles?

- The main difference between 304LN and 316LN stainless steel angles is the chemical composition and their respective corrosion resistance properties. 304LN stainless steel angles have a higher content of chromium and nickel, which provides good resistance to corrosion and oxidation in various environments. However, they may be more susceptible to chloride-induced stress corrosion cracking compared to 316LN stainless steel angles. On the other hand, 316LN stainless steel angles contain molybdenum in addition to chromium and nickel, which enhances their resistance to pitting and crevice corrosion, especially in chloride-containing environments. They are commonly used in marine and coastal applications where exposure to saltwater or other corrosive substances is frequent. In summary, while both 304LN and 316LN stainless steel angles offer good corrosion resistance, 316LN stainless steel angles provide superior protection against pitting and crevice corrosion in more aggressive environments.

- Q: Can stainless steel angles be used in balcony railings?

- Indeed, balcony railings can incorporate stainless steel angles. Thanks to its durability and resistance to corrosion, stainless steel proves itself as an ideal material for outdoor purposes like balcony railings. These angles, composed of stainless steel, offer not only structural reinforcement but also the creation of a robust and visually appealing railing system for balconies. By welding or bolting the angles together, a secure and enduring railing can be constructed, adhering to safety regulations. Moreover, stainless steel is a versatile material that can be effortlessly tailored to harmonize with the balcony's design and style, rendering it a highly favored option for balcony railings.

Send your message to us

Stainless Angle Steel Bar ASTM 316l with Customized Surface Treatment

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords