Q345 U shaped Channel Steel Hot Rolled Channel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Q345 U shaped Channel Steel Hot Rolled Channel

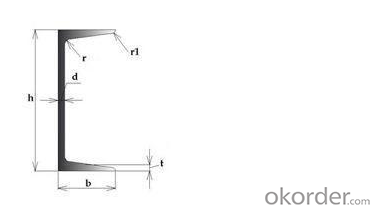

Main Structure of Hot Rolled Channel

| 1.Product size | Size : 5#--40# | ||||

| 2.Product length | Lengths : 6m--12m | ||||

| 3.product standard | Standard : GB, ASTM, JIS, DIN | ||||

| 4.product Grade | Grades : Q235B, Q345B, SS400 | ||||

| 5.Application | Used or building structures, vehicle | ||||

| manufacturing and other industrial structures | |||||

| 6.Customized requirement | Can produce special specification products | ||||

| as per our customers' requirement | |||||

| 7.Delivery time | 15-30 days after recieve the LC or pre-paid | ||||

| 8.Detail Package | Bundles, seaworthy wooden cases with or without | ||||

| edge protector, steel hoop and seals, or as per | |||||

| customers' requirements | |||||

Drawings And Detail Datas (help to know more detail information)

Specification:

Specification | h | b | d | t | Cm2 | (kg/m) |

5 | 50 | 37 | 4.5 | 7 | 6.93 | 5.44 |

6.3 | 63 | 40 | 4.8 | 7.5 | 8.45 | 6.63 |

8 | 80 | 43 | 5 | 8 | 10.24 | 8.04 |

10 | 100 | 48 | 5.3 | 8.5 | 12.74 | 10 |

12.6 | 126 | 53 | 5.5 | 9 | 15.69 | 12.37 |

14a | 140 | 58 | 6 | 9.5 | 18.51 | 14.53 |

14b | 140 | 60 | 8 | 9.5 | 21.31 | 16.73 |

16a | 160 | 63 | 6.5 | 10 | 21.95 | 17.23 |

16 | 160 | 65 | 8.5 | 10 | 25.15 | 19.74 |

18a | 180 | 68 | 7 | 10.5 | 25.69 | 20.17 |

18 | 180 | 70 | 9 | 10.5 | 29.29 | 22.99 |

FAQ:

How's your service?

A:1. Offer customers 24/7 service, whenever you need us, we are always here for you.

2. Immediate response. Your any inquiry will be replied within 24 hours.

3. Support small order quantity, for the first time cooperation customers, we can send you less quantity for trial order.

4. Support third party inspection company to inspect and check the quality and quantity before delivery.

Picture:

- Q: Can stainless steel angles be used for water treatment plants?

- Yes, stainless steel angles can be used for water treatment plants. Stainless steel is a corrosion-resistant material that is commonly used in industries where water is involved, such as water treatment plants. The angles provide structural support and are resistant to corrosion, making them ideal for use in these environments. Additionally, stainless steel angles can withstand high temperatures and pressures often found in water treatment processes. They also have excellent hygiene properties and are easy to clean, making them suitable for use in water treatment plants where sanitation is crucial. Overall, stainless steel angles are a reliable and durable choice for water treatment plant applications.

- Q: How do I calculate the weight of a stainless steel angle?

- To calculate the weight of a stainless steel angle, you need to know the dimensions of the angle and the density of stainless steel. First, measure the length, width, and thickness of the angle. These dimensions will be represented in inches or millimeters. Next, find the density of stainless steel. The density of stainless steel varies depending on the specific type, but on average, it is around 8 grams per cubic centimeter or 8000 kilograms per cubic meter. To calculate the volume of the stainless steel angle, multiply the length, width, and thickness together. If your dimensions are in inches, convert them to centimeters by multiplying by 2.54. If your dimensions are in millimeters, divide by 10 to get centimeters. Next, convert the volume to cubic meters by dividing by 1,000,000 if your dimensions are in centimeters. If your dimensions are already in meters, you can skip this step. Finally, multiply the volume by the density to get the weight of the stainless steel angle. Make sure the units are consistent - if your density is in kilograms per cubic meter and your volume is in cubic meters, the resulting weight will be in kilograms. If you used grams per cubic centimeter for density, the weight will be in grams. For example, let's say you have a stainless steel angle with dimensions of 10 inches length, 2 inches width, and 0.5 inches thickness. First, convert the dimensions to centimeters: 10 inches = 25.4 cm, 2 inches = 5.08 cm, 0.5 inches = 1.27 cm. Next, calculate the volume: 25.4 cm x 5.08 cm x 1.27 cm = 162.9 cm³. Since the density of stainless steel is approximately 8000 kg/m³, divide the volume by 1,000,000 to get cubic meters: 162.9 cm³ / 1,000,000 = 0.0001629 m³. Finally, multiply the volume by the density: 0.0001629 m³ x 8000 kg/m³ ≈ 1.3032 kg. Therefore, the weight of the stainless steel angle is approximately 1.3032 kilograms.

- Q: Can stainless steel angles be used in the aerospace industry?

- Indeed, the aerospace industry can utilize stainless steel angles. Renowned for its exceptional strength, resistance to corrosion, and durability, stainless steel proves to be an appropriate material for diverse applications in this field. In the construction of aircraft structures, engine components, and other vital aerospace parts, stainless steel angles find their purpose. Thanks to stainless steel's ability to withstand the harsh conditions and exposure to moisture and chemicals commonly encountered in aerospace operations, these angles exhibit remarkable resistance to corrosion. Furthermore, stainless steel's remarkable strength-to-weight ratio renders it an ideal option for crafting lightweight, yet resilient, structures within aircraft. All in all, stainless steel angles represent a dependable and adaptable material that satisfies the rigorous demands of the aerospace industry.

- Q: What are the different types of finishes available for stainless steel angles?

- There are several types of finishes available for stainless steel angles, each offering unique properties and aesthetic appeal. Some of the most common finishes include: 1. Mill Finish: This is the most basic finish, straight from the mill with no additional treatment. It has a dull, gray appearance and is often used in industrial applications where aesthetics are not a priority. 2. Brushed Finish: Also known as satin finish, this finish is achieved by brushing the stainless steel surface with a fine abrasive material. It creates a smooth, consistent surface with fine parallel lines, giving the angle a sleek and modern look. 3. Mirror Finish: This finish is achieved by polishing the stainless steel surface to a high shine, similar to a mirror. It requires extensive polishing and buffing to remove any imperfections, resulting in a highly reflective surface. Mirror finish is commonly used in architectural applications and for decorative purposes. 4. Bead Blasted Finish: In this finish, fine glass beads are blasted onto the stainless steel surface using compressed air. This creates a textured, matte appearance with a uniform pattern of tiny indentations. Bead blasted finish is often used in high-traffic areas or where a non-reflective surface is desired. 5. Powder Coated Finish: This finish involves applying a layer of dry powder paint onto the stainless steel surface and then baking it to create a durable, protective coating. Powder coating provides a wide range of color options and can be used to enhance the aesthetics and corrosion resistance of stainless steel angles. 6. PVD Coating: Physical Vapor Deposition (PVD) is a process where a thin layer of metal or metal alloy is deposited onto the stainless steel surface. This creates a decorative, durable finish with various colors and patterns. PVD coatings are commonly used in architectural and decorative applications. It's important to note that the availability of these finishes may vary depending on the manufacturer and the specific requirements of the project. Additionally, stainless steel angles can also be customized with specialized finishes to meet specific needs, such as anti-fingerprint coatings or anti-microbial finishes.

- Q: What are the maximum load capacities of stainless steel angles?

- The maximum load capacities of stainless steel angles can vary depending on various factors such as the size, thickness, and grade of the stainless steel angle. Generally, stainless steel angles are known for their high strength and load-bearing capabilities. To determine the maximum load capacity, it is important to consider the specific requirements and specifications of the stainless steel angle being used. The load capacity can be influenced by factors such as the length and width of the angle, the type of load being applied (vertical or horizontal), the support structure, and the method of installation. Typically, stainless steel angles are designed to withstand substantial loads due to their durable and corrosion-resistant properties. However, it is essential to consult with structural engineers or reference technical resources such as load tables provided by stainless steel manufacturers or industry standards to obtain accurate information regarding the maximum load capacities of specific stainless steel angles. By considering the necessary factors and employing proper engineering practices, the maximum load capacities of stainless steel angles can be determined and utilized effectively in various applications such as construction, manufacturing, and structural engineering.

- Q: Can stainless steel angles be used in conveyor systems?

- Yes, stainless steel angles can be used in conveyor systems. Stainless steel angles offer durability, corrosion resistance, and strength, making them suitable for various industrial applications, including conveyor systems.

- Q: What is the weight calculation formula for stainless steel angles?

- To calculate the weight of a stainless steel angle, you can use the following formula: Multiply the density of stainless steel by the cross-sectional area of the angle. The density of stainless steel is typically 7.9 g/cm³ or 7900 kg/m³. To find the cross-sectional area of the angle, multiply the thickness of the stainless steel angle by the sum of its width and height. These measurements are usually in millimeters (mm). Hence, the weight (W) of a stainless steel angle can be determined using the equation: W = (Density) x (Thickness) x (Width + Height) Where W represents the weight of the angle in kilograms (kg).

- Q: How does stainless steel angle perform in corrosive liquids?

- Stainless steel angle possesses exceptional corrosion resistance properties, making it extremely suitable for utilization in environments with corrosive liquids. The inclusion of alloying elements, such as chromium, nickel, and molybdenum, within stainless steel results in the formation of a protective oxide layer on the material's surface. This layer, known as the passive layer, acts as a barrier, effectively safeguarding the underlying metal from direct contact with corrosive substances. By preventing the metal from interacting directly with corrosive liquids, the passive layer shields it from harm. This unique characteristic enables stainless steel angle to excel in corrosive liquid environments. Additionally, the specific grade of stainless steel employed in the angle's manufacturing significantly impacts its performance. Grades such as 316 stainless steel, with higher quantities of alloying elements, exhibit even greater resistance to corrosion. These grades prove particularly beneficial in highly corrosive environments where the angle may encounter aggressive chemicals or saltwater. In conclusion, stainless steel angle demonstrates exceptional corrosion resistance and excels in corrosive liquid environments. Its ability to establish a protective oxide layer, coupled with the presence of alloying elements, renders it a dependable choice for applications that prioritize resistance to corrosion.

- Q: Can stainless steel angles be used in the production of construction machinery?

- Yes, stainless steel angles can be used in the production of construction machinery. Stainless steel is widely used in the construction industry due to its excellent strength, corrosion resistance, and durability. Stainless steel angles, in particular, are commonly used in the fabrication of structural components and supports in construction machinery. They provide stability, structural integrity, and longevity to the equipment. Additionally, stainless steel angles can withstand heavy loads, extreme temperatures, and harsh environmental conditions, making them ideal for construction machinery that operates in diverse settings.

- Q: Can stainless steel angles be used for signage?

- Certainly! Signage can indeed employ stainless steel angles. This material, known for its durability and resistance to corrosion, proves ideal for outdoor usage, particularly in the realm of signage. Stainless steel angles enable the construction of frames or supports for signs, offering stability and a polished, sophisticated aesthetic. Moreover, this material's ease of cleaning and maintenance guarantees sustained quality for signage over an extended period. In addition, stainless steel exudes a contemporary and fashionable appearance, rendering it a favored option across diverse signage categories, be it commercial, residential, or industrial applications.

Send your message to us

Q345 U shaped Channel Steel Hot Rolled Channel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords