Hot Rolled Steel Angle Q345

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Steel Angle Q345

1. Standards: GB,ASTM,BS,AISI,DIN,JIS

2. Length:6m,9m,12m

3. Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400;

SS540.

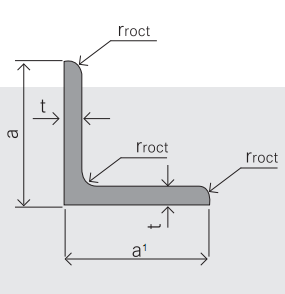

4. Sizes:

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Chemical data: %

C | Mn | S | P | Si |

0.14-0.22 | 0.30-0.65 | ≤0.050 | ≤0.045 | ≤0.30 |

Usage & Applications of Equal Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Hot Rolled Steel Angle Q345

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q:How do steel angles perform in terms of water resistance or waterproofing?

- Steel angles are not inherently water-resistant or waterproof. However, their performance in terms of water resistance can be improved through various methods such as galvanization or coating. These processes create a protective layer on the steel surface, enhancing its resistance to water and preventing rust or corrosion. It is important to apply appropriate measures to ensure the water resistance of steel angles in order to maintain their structural integrity and longevity.

- Q:How do steel angles perform in high-humidity environments?

- Steel angles perform well in high-humidity environments due to their corrosion-resistant properties. The presence of moisture in the air can often lead to rust and corrosion of metals, but steel angles are designed to withstand these conditions. They are typically made from stainless steel or galvanized steel, both of which have a protective layer that prevents rust formation. This makes them highly suitable for use in areas with high humidity, such as coastal regions or industrial settings where moisture is prevalent. Additionally, steel angles are durable and have a long lifespan, further enhancing their performance in high-humidity environments.

- Q:Can steel angles be used for railings or barriers?

- Yes, steel angles can indeed be used for railings or barriers. Steel angles are commonly used in construction and are known for their strength and durability. They provide a sturdy and reliable structure for railings and barriers, ensuring the safety and security of the area. Steel angles can be easily welded or bolted together, allowing for easy installation and customization. Additionally, steel angles can be coated or painted to enhance their appearance and protect against rust and corrosion. Overall, steel angles are a popular choice for railings and barriers due to their strength, versatility, and longevity.

- Q:Can steel angles be used for modular furniture or fixtures?

- Yes, steel angles can definitely be used for modular furniture or fixtures. Steel angles are versatile and strong structural components that can be easily incorporated into modular furniture designs. They provide stability and support to the overall structure, making them ideal for creating modular pieces that are sturdy and durable. Steel angles can be used as corner brackets or supports for shelves, cabinets, or other modular components. They can be easily cut, welded, or drilled to fit specific design requirements, allowing for flexibility in creating different configurations or sizes of modular furniture. Additionally, steel angles can be powder coated or painted in different colors to match the desired aesthetic of the furniture or fixtures. The use of steel angles in modular furniture or fixtures also ensures longevity, as they are resistant to wear and tear, corrosion, and impact. This makes them suitable for both indoor and outdoor applications. Moreover, steel angles are readily available and cost-effective, making them a practical choice for modular furniture or fixture manufacturing. In conclusion, steel angles are an excellent choice for creating modular furniture or fixtures due to their strength, versatility, and durability. They provide stability and support to the structure, can be easily customized, and offer long-lasting performance. Whether it is for residential or commercial use, steel angles can be utilized to create modular furniture or fixtures that are both functional and aesthetically pleasing.

- Q:What is the maximum load a steel angle can support?

- The load capacity of a steel angle depends on various factors including its dimensions, the type and grade of steel used, and the method of support. Steel angles are generally known for their strength and ability to bear heavy loads. They are commonly used in construction and structural applications to provide support and stability to different structures. To determine the maximum load that a specific steel angle can support, it is necessary to refer to engineering tables or reference materials that provide load capacity data for different steel angles. These resources take into account factors such as the angle's length, width, and thickness, the type of steel used (e.g., mild steel or high-strength steel), and the method of support (e.g., cantilever or simply supported). It is important to highlight that determining the maximum load a steel angle can bear typically involves conducting tests in a controlled environment to ensure safety and reliability. These tests involve gradually increasing the load applied to the angle until it reaches its maximum load-bearing capacity or fails. The results of these tests are used to establish load capacity guidelines for engineers and builders. Therefore, without specific information regarding the dimensions, type of steel, and method of support, it is not possible to provide an exact maximum load value for a steel angle. It is recommended to consult relevant engineering references, structural engineers, or manufacturers to obtain accurate load capacity information for a specific steel angle.

- Q:Can steel angles be used in equipment supports?

- Yes, steel angles can be used in equipment supports. They provide structural stability and are commonly used in various industries to support equipment and machinery.

- Q:How do you calculate the second moment of area for a steel angle?

- In order to determine the second moment of area for a steel angle, a step-by-step procedure must be followed. The following guidelines outline how this can be accomplished: 1. Initiate the process by sketching the cross-section of the steel angle on either paper or a CAD software platform. Ensure that all dimensions are accurately labeled. 2. Partition the angle into smaller geometric shapes, such as rectangles and triangles, as these are simpler to calculate the second moment of area for. 3. Compute the individual second moments of area for each geometric shape. The formula employed to determine the second moment of area, also known as the moment of inertia, varies depending on the shape. For rectangles, the formula is (b * h^3) / 12, where b represents the base and h denotes the height. For triangles, the formula is (b * h^3) / 36, with b and h representing the base and height respectively. Adjust the formulas accordingly based on the orientation and positioning of the shapes within the angle. 4. Sum up the individual second moments of area for all the shapes within the angle. If there are any openings or cutouts present, subtract their respective second moments of area from the total. 5. Once the second moments of area have been calculated for all the shapes and adjustments have been made for any cutouts, add them together to obtain the total second moment of area for the steel angle. It is important to emphasize that the second moment of area signifies the resistance of a cross-section to bending. This parameter is critical in structural analysis and design, as it aids in determining the strength and stability of a structural member under applied loads.

- Q:Can steel angles be used for sign or billboard support structures?

- Steel angles can serve as support structures for signs or billboards. They are commonly utilized in construction due to their robustness and longevity. These angles offer exceptional support for a range of structures, including sign or billboard installations. They are adaptable and can be effortlessly customized and installed to meet the precise demands of the signage or billboard. With their ability to endure substantial loads and adverse weather conditions, steel angles are a perfect choice for supporting these structures. Moreover, they can be painted or coated to enhance their aesthetic appeal and shield them from corrosion, thus prolonging their lifespan.

- Q:Can steel angles be used in modular construction?

- Yes, steel angles can indeed be used in modular construction. They are commonly used as structural elements to provide stability and support in modular buildings.

- Q:What are the different types of steel angles used in fencing and gates?

- There are several different types of steel angles that are commonly used in fencing and gates. One of the most common types is the equal angle, also known as L-shaped angle. This type of angle has equal length sides and is commonly used for vertical and horizontal bracing in fencing and gates. Another type is the unequal angle, which has one longer side and one shorter side. This type of angle is often used for diagonal bracing in fencing and gates, as it provides additional strength and stability. There is also the rounded edge angle, which has rounded edges instead of sharp corners. This type of angle is often used in fencing and gates to reduce the risk of injury, as the rounded edges are less likely to cause cuts or other accidents. Additionally, there are slotted angles, which have pre-drilled holes along the length of the angle. These holes allow for easy attachment of fencing and gate components, such as panels or hinges. Finally, there are galvanized angles, which have been coated with a layer of zinc to protect against rust and corrosion. This type of angle is ideal for outdoor fencing and gates, as it provides long-lasting durability and resistance to the elements. Overall, the different types of steel angles used in fencing and gates offer various benefits in terms of strength, stability, safety, ease of installation, and resistance to rust and corrosion. The specific type of angle used will depend on the specific requirements and preferences of the fencing or gate project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Angle Q345

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords