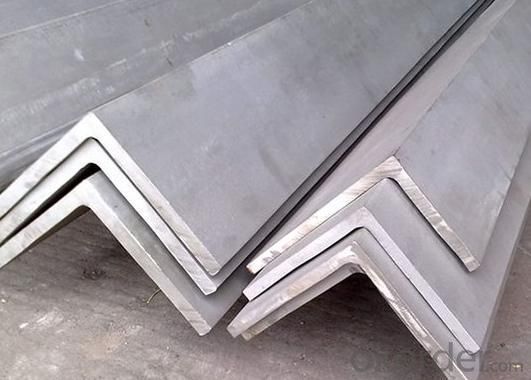

1.4301 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Angles

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your

requirement

10. Application: Construction, Marine, Industry and so on

|

Name |

Stainless Steel Angles | ||||||

|

Standard |

ASTM A554, A312, A249, A269 and A270 | ||||||

|

Material Grade |

304,316,201,202, 316L,430 | ||||||

|

Length |

6m or as customers' request | ||||||

|

Tolerance |

a) thickness: +/-0. 15mm | ||||||

|

| |||||||

|

b) Length:+/-4. 5mm - 0mm | |||||||

|

Surface |

180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

|

Application |

Decoration construction, upholstery, industry instruments | ||||||

|

Test |

Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

|

Chemical Composition of Material |

Composition

Material |

201 |

202 |

304 |

316L |

430 | |

|

C |

≤0.15 |

≤0.15 |

≤0.08 |

≤0.08 |

≤0.12 | ||

|

Si |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 |

≤1.00 | ||

|

Mn |

5.5-7.5 |

7.5-10 |

≤2.00 |

≤2.00 |

≤1.00 | ||

|

P |

≤0.06 |

≤0.06 |

≤0.045 |

≤0.045 |

≤0.040 | ||

|

S |

≤0.03 |

≤0.03 |

≤0.030 |

≤0.030 |

≤0.030 | ||

|

Cr |

16-18 |

17-19 |

18-20 |

16-18 |

16-18 | ||

|

Ni |

3.5-5.5 |

4-6 |

8-10.5 |

10-14 |

| ||

|

Mo |

|

|

|

2.0-3.0 |

| ||

|

Mechanical Property |

Material Item |

201 |

202 |

304 |

316L | ||

|

Tensile Strength |

≥535 |

≥520 |

≥520 |

≥520 | |||

|

Yield Strength |

≥245 |

≥205 |

≥205 |

≥205 | |||

|

Extension |

≥30% |

≥30% |

≥35% |

≥35% | |||

|

Hardness (HV) |

<253 |

<253 |

<200 |

<200 | |||

- Q: Are stainless steel angles corrosion-resistant?

- Yes, stainless steel angles are corrosion-resistant due to the presence of chromium which forms a protective layer on the surface, preventing rust and corrosion.

- Q: What is the resistance to pitting of stainless steel angles?

- The resistance to pitting of stainless steel angles is typically quite high due to the material's inherent corrosion-resistant properties.

- Q: Can stainless steel angles be used for elevator interiors?

- Yes, stainless steel angles can be used for elevator interiors. Stainless steel is a durable and corrosion-resistant material, making it suitable for high-traffic areas like elevator interiors. Additionally, its sleek and modern appearance enhances the aesthetic appeal of the elevator.

- Q: Can stainless steel angles be used outdoors?

- Yes, stainless steel angles can be used outdoors. Stainless steel is a highly corrosion-resistant material, making it suitable for outdoor applications where it will be exposed to elements such as rain, humidity, and temperature fluctuations. Stainless steel angles are often used in construction, architectural projects, and outdoor furniture due to their durability and resistance to rust and corrosion. However, it is important to note that the specific grade of stainless steel used should be selected based on the environment and level of exposure to ensure optimal performance and longevity.

- Q: Can stainless steel angles be used in sports infrastructure?

- Certainly, sports infrastructure can indeed incorporate the utilization of stainless steel angles. Renowned for its durability and resistance to corrosion, stainless steel emerges as a fitting material for a diverse range of applications within sports infrastructure. Construction of bleachers, grandstands, fencing, and other structural elements can employ stainless steel angles. Thanks to their remarkable strength-to-weight ratio, these angles ensure stability and long-lasting performance, even in the face of adverse environmental conditions. Moreover, stainless steel angles boast aesthetic appeal and can be conveniently maintained, rendering them a favored option in sports facilities.

- Q: Can stainless steel angles be customized or fabricated to specific requirements?

- Yes, stainless steel angles can be customized or fabricated to specific requirements. They can be cut, shaped, welded, and finished according to the desired specifications, making them highly versatile and adaptable for various applications.

- Q: Are stainless steel angles available in different colors?

- No, stainless steel angles are typically not available in different colors as stainless steel has a natural silver color that is maintained throughout its composition.

- Q: What are the common uses of 90-degree stainless steel angles?

- 90-degree stainless steel angles are commonly used in construction and fabrication projects for various purposes. One of the common uses is in structural applications, where they are used to provide support and reinforcement to buildings, bridges, and other structures. These angles are often used to create corners or edges that are perpendicular to each other, adding stability and strength to the overall structure. Another common use of 90-degree stainless steel angles is in the manufacturing industry. They are used in the fabrication of machinery, equipment, and conveyor systems. These angles can be used to create frames or brackets that hold components in place, ensuring proper alignment and functioning of the machinery. In addition, 90-degree stainless steel angles find applications in the architectural and interior design sectors. They are used to create decorative elements such as handrails, staircases, and furniture. The clean and polished appearance of stainless steel adds a sleek and modern touch to these design features. Furthermore, these angles are often utilized in the automotive and transportation industries. They can be found in the construction of trailers, truck beds, and vehicle frames. The durability and corrosion resistance of stainless steel make it an ideal choice for these applications, as it can withstand harsh environmental conditions and heavy loads. Overall, the common uses of 90-degree stainless steel angles span across various industries including construction, fabrication, manufacturing, architecture, and transportation. Their versatility, strength, and aesthetic appeal make them a popular choice for a wide range of applications.

- Q: Can stainless steel angles be used in the construction of storage tanks?

- Yes, stainless steel angles can be used in the construction of storage tanks. Stainless steel angles are a versatile and durable material that is highly resistant to corrosion and can withstand high temperatures and pressure. They are commonly used in various industries, including storage tank construction, due to their excellent mechanical properties and ability to withstand harsh environmental conditions. Stainless steel angles provide structural support and stability to the storage tanks, ensuring their integrity and longevity. Additionally, stainless steel angles can be easily fabricated and welded, making them suitable for constructing storage tanks of different sizes and shapes.

- Q: Are stainless steel angles resistant to UV rays?

- Stainless steel angles, in general, exhibit resistance to UV rays. The remarkable ability of stainless steel to withstand corrosion and oxidation, including shielding against the harmful impact of UV radiation, is widely acknowledged. This is attributed to the existence of chromium in stainless steel, which generates a protective oxide layer on the surface, safeguarding it from UV rays and averting rust and deterioration. Nevertheless, it is essential to acknowledge that the level of resistance may differ based on the particular grade and finish of the stainless steel angle.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

1.4301 Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords