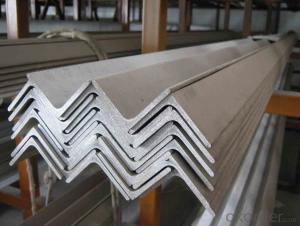

High quality angle steel GB Q235B 20-250MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Angle Steel Details:

| Minimum Order Quantity: | 25mtons | Unit: | m.t. | Loading Port: | China Main Port |

| Supply Ability: | 80000-100000MTS/YEAR | Payment Terms: | TT or LC |

Product Description:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

vv

- Q: Can steel angles be used as lintels?

- Yes, steel angles can be used as lintels. Lintels are structural elements that provide support over openings such as doors and windows, and steel angles are commonly used due to their strength and load-bearing capabilities. They can effectively distribute the load of the structure above the opening and ensure the stability and integrity of the building.

- Q: Are steel angles suitable for outdoor furniture?

- Steel angles are indeed appropriate for outdoor furniture. Steel is known for its durability and strength, enabling it to endure diverse weather conditions. This quality makes it an exceptional selection for outdoor furniture. Steel angles contribute to stability and structural support, guaranteeing that the furniture can bear heavy loads and remain firm. Furthermore, when properly treated, steel is resistant to rust and corrosion, which is crucial for outdoor furniture exposed to moisture and changing weather. In addition, steel angles offer a sleek and contemporary aesthetic, enabling versatile design possibilities for outdoor furniture. In summary, the durability, strength, and resistance to environmental elements make steel angles a dependable and long-lasting option for outdoor furniture.

- Q: How do steel angles provide structural support?

- Steel angles provide structural support by distributing and transferring loads and forces in various structures. They are commonly used as braces or brackets to reinforce and stabilize beams, columns, and other members. The L-shaped design of steel angles allows them to resist bending and provide strength and rigidity to the structure. They can be bolted or welded to the main structural components, thereby increasing their load-carrying capacity and overall stability.

- Q: Can steel angles be used in outdoor or exposed applications?

- Yes, steel angles can be used in outdoor or exposed applications. Steel is a highly durable and weather-resistant material, making steel angles suitable for withstanding outdoor conditions. Additionally, steel angles can be treated or coated to provide further protection against rust and corrosion, making them a reliable choice for outdoor and exposed applications.

- Q: What are the different finishes available for steel angles?

- Steel angles can be finished in various ways, depending on the desired appearance and level of protection. One popular option is hot-dip galvanizing, where the angle is immersed in molten zinc to create a corrosion-resistant coating. This finish is ideal for outdoor use or in environments with high humidity or exposure to chemicals. Another choice is powder coating, which involves applying a dry powder to the angle and then baking it in an oven to create a durable finish. Powder coatings come in a wide range of colors and textures, allowing for customization to meet specific design needs. They also provide good corrosion resistance and are commonly used in architectural and decorative applications. For a more natural look, the angle can be left untreated or given a mill finish. The mill finish refers to the smooth, slightly reflective appearance that occurs during the manufacturing process. This finish is often used in structural applications where aesthetics are not the main concern. Lastly, the angle can be painted or coated with enamel. This involves applying a liquid paint or enamel coating to the surface, providing both rust protection and an improved appearance. Painted finishes come in various colors and can be tailored to specific design requirements. Ultimately, the choice of finish for steel angles depends on factors such as the desired level of corrosion resistance, aesthetic preferences, and the specific application or environment in which the angles will be used.

- Q: Are steel angles resistant to impact or vibration?

- Steel angles are generally resistant to both impact and vibration. Steel is known for its strength and toughness, making it highly resistant to impact. It can absorb and distribute the force generated by an impact, preventing structural damage. Additionally, steel angles have a high natural frequency, which means they can withstand vibrations without experiencing significant deformation or failure. However, the resistance of steel angles to impact and vibration may vary depending on the specific grade and thickness of the steel, as well as the intensity and duration of the impact or vibration. It is important to consider the specific requirements and conditions of the application when determining the suitability of steel angles for impact and vibration resistance.

- Q: Can steel angles be used in the construction of railway bridges?

- Yes, steel angles can be used in the construction of railway bridges. Steel angles are versatile structural elements that can be used in various applications, including bridge construction. They are commonly used in the fabrication of bridge girders, braces, and supports. Steel angles provide excellent strength and load-bearing capabilities, making them suitable for railway bridges that require high structural integrity and durability. Additionally, steel angles can be easily welded, bolted, or riveted together, allowing for efficient and cost-effective construction. Overall, steel angles are a viable and commonly used component in the construction of railway bridges.

- Q: How do you determine the appropriate thickness of a steel angle for a specific application?

- To calculate the suitable thickness of a steel angle for a specific purpose, several factors must be taken into consideration. Firstly, it is crucial to comprehend the load or weight that will be exerted on the steel angle. This includes both the static load, which refers to the continuous weight the angle will bear, and the dynamic load, which signifies any intermittent additional force. The magnitude of the load will determine the strength requirements of the steel angle. Secondly, the length of the steel angle needs to be accounted for. Longer angles will experience more deflection and bending, thus necessitating a thicker angle to ensure adequate rigidity and prevent deformation under the load. Another critical factor to consider is the type of steel being utilized. Different steel grades possess varying strength properties, and the appropriate thickness will depend on the specific grade. It is essential to consult the material specifications and standards to ensure the selected steel angle meets the necessary strength and durability criteria for the intended application. Additionally, the support conditions and the method of attachment should be taken into account. The manner in which the steel angle is connected to other structural elements will impact its load-bearing capacity. If the angle is bolted or welded to other components, its thickness must be selected to suit the particular connection method and accommodate any additional stresses induced during the attachment process. Lastly, it is important to adhere to any applicable industry standards, codes, or regulations when determining the suitable thickness of a steel angle. These standards often provide guidelines or calculations for selecting the correct size and thickness based on the intended application, load, and other design factors. In conclusion, determining the appropriate thickness of a steel angle for a specific application necessitates considering factors such as the load magnitude, length, steel grade, support conditions, and attachment method. Consulting material specifications, industry standards, and seeking professional advice can ensure that the chosen steel angle meets the required strength and durability specifications.

- Q: How do you prevent corrosion on steel angles?

- To prevent corrosion on steel angles, there are several preventive measures that can be taken: 1. Surface preparation: Before applying any protective coating, it is crucial to properly clean the steel angles to remove any dirt, rust, or other contaminants. This can be done through abrasive blasting, power tool cleaning, or chemical cleaning methods. 2. Protective coatings: Applying a protective coating on steel angles is one of the most effective ways to prevent corrosion. There are various types of coatings available, such as paint, epoxy, zinc-rich coatings, or galvanization. These coatings act as a barrier between the steel and the surrounding environment, preventing moisture and corrosive elements from coming into contact with the metal. 3. Cathodic protection: This method uses sacrificial metals or an impressed current to protect the steel angles from corrosion. Sacrificial metals, such as zinc or aluminum, are connected to the steel angles and corrode in place of the steel when exposed to corrosive elements. Impressed current systems use an external power source to provide a protective current to the steel, inhibiting corrosion. 4. Environmental control: Controlling the environment in which steel angles are installed can also help prevent corrosion. For example, reducing exposure to moisture, humidity, or corrosive chemicals can significantly extend the lifespan of the steel. This can be achieved by proper ventilation, ensuring proper drainage, or using protective coatings specifically designed for harsh environments. 5. Regular maintenance: Regular inspection and maintenance of steel angles are essential to identify any signs of corrosion early on. Any damaged or corroded areas should be repaired promptly to prevent further deterioration. Additionally, regular cleaning and reapplication of protective coatings can help maintain the integrity of the steel angles. By implementing a combination of these preventive measures, it is possible to significantly reduce the risk of corrosion on steel angles, prolong their lifespan, and maintain their structural integrity.

- Q: Are steel angles suitable for outdoor staircases?

- Yes, steel angles are suitable for outdoor staircases. Steel angles have high strength and durability, making them ideal for withstanding outdoor elements such as weather conditions and heavy foot traffic. Additionally, steel angles can be coated or painted to enhance their resistance to corrosion, further increasing their suitability for outdoor staircases.

Send your message to us

High quality angle steel GB Q235B 20-250MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords