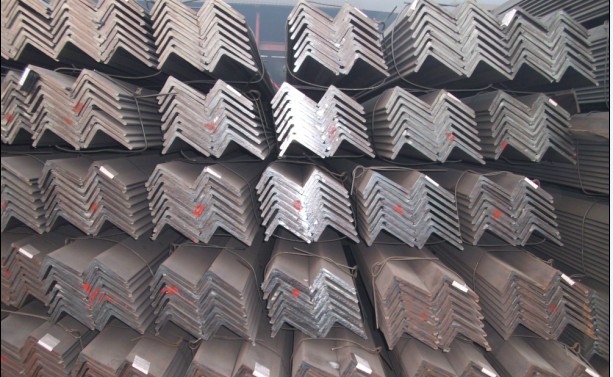

High quality angle steel 20-250mm hot rolled GB Q235

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:Specificationsangle steel angle steel angle steel agle steel angle steel

Angle called angle, the steel strip is perpendicular to each other on both sides into angular.Divided into equilateral angle steel and ranging from side angle. Two equilateral angle steel edge width is the same. The specification is expressed by edge width * width * thick edgenumber of millimeters. Such as "/ 30 x 30 x 3", namely that equilateral angle steel edge widthof 30 mm, 3 mm thick edge. Can also be used to model representation, model is the wideangle 3# cm, such as. The model does not represent the same type in different edge thickness size, thus in the contract and other documents on the angle of the edge width, edgethick size fill in complete, avoid alone represented by type. Hot rolled equilateral angle steelspecifications for 2#-20#. Angle according to the different needs of structure composed of a variety of stress components, can also be used as a component of the connections between the. Widely used in a variety of architectural and engineering structures, such as beams,bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reactor,container frame and warehouse. Mainly divided into equilateral angle steel, equilateral angle steel two categories, includingunequal angle can be divided into equal thickness and unequal thickness ranging from two. Angle specifications with the side length of the size and edge thickness. At present, the domestic steel specifications for 2 - 20 cm in length, number of numbers, the same horn steel often have 2 - 7 different edge thickness. The actual size and inlet angle marked on both sides of the thickness and indicate the relevant standards. The general length of more than 12.5cm for large angle steel, 12.5cm - 5cm for the medium angle, length of 5cm for smallangle. Inlet and outlet angle steel orders generally required the use specifications in the steel,carbon structural steel grades as appropriate. Is the angle in addition to standard number, nospecific composition and performance series. Angle steel delivery length is divided into fixed length, size two, domestic steel length range is3 - 9m, 4 12M, 4 19m, 6 19m four range according to different specifications. Japanese steellength ranges from 6 to 15m. Section of unequal angle height according to the long edge of the width to calculate the non equilateral angle steel. Refer to section angle and side length is not equal to the steel. Is a kind of angle steel. The length from 25mm * 16mm to 200mm * l25mm. By the hot rolling mill rolling in. General scalene angle steel specifications: thickness of 4-18mm / 50*32-- / 200*125 Equilateral angle steel is widely used in all kinds of metal structures, bridges, machinery manufacturing and shipbuilding industry, all kinds of architectural and engineering structures,such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace,reactor, container frame and warehouse etc. 1.Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load. 2.With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request. 3. Marks: Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port. Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer. If loading by container the marking is not needed, but we will prepare it as customer request. |

- Q: Are steel angles suitable for architectural applications?

- Yes, steel angles are suitable for architectural applications. They are commonly used in construction projects to provide structural support, such as in building frames, facades, and bridges. Steel angles offer excellent strength and durability, making them a reliable choice for architects seeking a versatile and long-lasting material for their designs.

- Q: What is the maximum temperature steel angles can withstand?

- The maximum temperature that steel angles can withstand depends on the specific grade of steel used. Generally, carbon steel angles can withstand temperatures up to around 600-650 degrees Celsius, while stainless steel angles can withstand higher temperatures, typically up to around 900-1100 degrees Celsius. However, it is important to consult the manufacturer's specifications for the specific steel grade being used to determine its maximum temperature tolerance.

- Q: Can steel angles be used for framing or supporting exterior façade elements?

- Yes, steel angles can be used for framing or supporting exterior façade elements. Steel angles provide structural support and stability, making them suitable for framing and supporting various components of an exterior façade, such as windows, doors, cladding, and signage. They offer strength, durability, and versatility, making them a popular choice in architectural and construction applications.

- Q: Can steel angles be used for pipe support systems?

- Indeed, pipe support systems can indeed utilize steel angles. In construction and engineering ventures, steel angles are frequently employed due to their exceptional durability, stability, and adaptability. When employed as pipe supports, steel angles furnish a robust and dependable framework for securely holding pipes in position. They can effortlessly be joined through welding or bolting to other structural elements, rendering them suitable for a variety of pipe support applications. Furthermore, steel angles can be fabricated and tailored to satisfy specific requirements, encompassing diverse pipe sizes and load-bearing capacities. In summary, owing to their resilience and capacity to withstand substantial loads, steel angles remain a favored option for pipe support systems.

- Q: How do steel angles perform in terms of fire resistance?

- Steel angles generally have good fire resistance due to the inherent properties of steel. Steel is a non-combustible material, meaning it does not burn or contribute to the spread of fire. Steel angles are often used in structural applications where fire protection is required, such as in building construction or industrial facilities. In the event of a fire, steel angles can withstand high temperatures without losing their structural integrity. This is because steel has a high melting point and does not weaken or deform easily under heat. Additionally, steel has a low thermal conductivity, meaning it does not transfer heat quickly, which further enhances its fire resistance. However, it is important to note that while steel angles have good fire resistance, they can still be affected by fire if exposed to extremely high temperatures for an extended period. In such cases, steel can experience significant thermal expansion and may eventually lose strength. Therefore, it is crucial to provide appropriate fire protection measures, such as fire-resistant coatings or fireproofing materials, to enhance the fire resistance of steel angles in critical applications. Overall, steel angles are considered to have favorable fire resistance properties and are widely used in various industries where fire protection is essential. However, proper fire safety measures should always be implemented to ensure the highest level of fire resistance and minimize any potential risks associated with fire exposure.

- Q: What are the different types of steel angles connections for joists?

- Joists commonly employ several types of steel angle connections. These options include: 1. Welded Connection: The simplest and most prevalent connection involves directly welding the steel angles to the joists. This method provides a sturdy and inflexible connection, albeit requiring skilled labor and additional welding time. 2. Bolted Connection: This connection involves fastening the steel angles to the joists using bolts or screws. It allows for easier installation and disassembly if necessary. However, it may not be as robust as a welded connection and may necessitate periodic bolt tightening. 3. Gusset Plate Connection: A flat steel plate known as a gusset plate connects the steel angles to the joists. Typically, this plate is secured by welding or bolting to both the angles and the joists, enhancing the connection's strength and stability. 4. Clip Angle Connection: L-shaped brackets called clip angles attach to the joists and steel angles using bolts or screws. This method offers a straightforward and efficient means of connecting angles to the joists, with the added benefit of easy adjustment or replacement. 5. Shear Plate Connection: This connection type employs a thick steel plate with holes, known as a shear plate, to link the steel angles to the joists. Like the gusset plate connection, the shear plate is usually welded or bolted to both the angles and the joists, ensuring a robust and secure connection. The selection of a particular steel angle connection method depends on factors such as load requirements, installation ease, and cost considerations, as each option presents its own advantages and disadvantages.

- Q: Are there any environmental benefits of using steel angles?

- Yes, there are several environmental benefits of using steel angles. Firstly, steel is a highly sustainable material as it is 100% recyclable without losing its strength or quality. This reduces the need for new steel production and saves energy and resources. Additionally, steel angles have a long lifespan and require minimal maintenance, resulting in lower lifecycle costs and reduced environmental impact. Furthermore, steel is resistant to natural elements, such as fire and corrosion, which increases its durability and minimizes waste. Overall, choosing steel angles contributes to a more sustainable and eco-friendly construction industry.

- Q: What are the different types of steel angles used in manufacturing?

- There are several types of steel angles commonly used in manufacturing, including equal angles, unequal angles, L-shaped angles, and T-shaped angles. These angles are used in various industries and applications, such as construction, engineering, and manufacturing of machinery and equipment.

- Q: Can steel angles be used in playground or recreational equipment?

- Yes, steel angles can be used in playground or recreational equipment. Steel angles are a versatile and strong structural material that can be used for various purposes in playground or recreational equipment. They provide stability, support, and durability, making them suitable for use in structures such as climbing frames, swing sets, slides, and other equipment. Steel angles are commonly used to create frames, posts, and supports in playground equipment due to their ability to withstand heavy loads, impact forces, and harsh weather conditions. Additionally, steel angles can be easily customized and fabricated to meet specific design requirements, ensuring the safety and functionality of the equipment.

- Q: What are the considerations for selecting the appropriate steel angle thickness?

- When selecting the appropriate steel angle thickness, there are several considerations to take into account. 1. Structural requirements: The first and most important consideration is the structural requirements of the project. This includes the load-bearing capacity, support requirements, and any specific design codes or standards that need to be followed. The steel angle thickness should be chosen in a way that ensures the structural integrity of the project. 2. Application: The application of the steel angle also plays a significant role in determining the appropriate thickness. Different applications have different demands in terms of strength, durability, and resistance to environmental factors. For example, if the steel angle is intended to be used in a corrosive environment, a thicker thickness may be required to provide better protection against corrosion. 3. Cost-effectiveness: Cost is always an important consideration in any construction project. While thicker steel angles may offer greater strength and stability, they can also be more expensive. It is essential to strike a balance between the required strength and the available budget to ensure cost-effectiveness. 4. Manufacturing and fabrication limitations: The selected steel angle thickness should be within the manufacturing and fabrication capabilities of the manufacturer. It is crucial to consider the availability of the desired thickness and the feasibility of producing the required dimensions. 5. Aesthetic considerations: In some cases, the appearance of the steel angle may be a factor to consider. Thicker angles may have a more substantial and visually appealing look, which can be desirable in certain architectural or design applications. 6. Availability and standard sizes: Availability of steel angles in different thicknesses and standard sizes can also influence the selection process. It is often more convenient and cost-effective to choose a thickness that is readily available in the market. In conclusion, selecting the appropriate steel angle thickness requires careful consideration of structural requirements, application demands, cost-effectiveness, manufacturing limitations, aesthetic preferences, and the availability of standard sizes. By taking all these factors into account, one can make an informed decision that meets the project's needs and ensures the desired level of strength and durability.

Send your message to us

High quality angle steel 20-250mm hot rolled GB Q235

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords