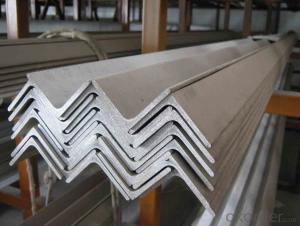

Angle steel GB Q235B 20-250MM hot rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Angle Steel Details:

| Minimum Order Quantity: | 25mtons | Unit: | m.t. | Loading Port: | China Main Port |

| Supply Ability: | 80000-100000MTS/YEAR | Payment Terms: | TT or LC |

Product Description:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: How do steel angles differ from steel channels?

- Steel angles and steel channels are frequently utilized in construction and engineering for their structural properties. However, they vary in terms of shape and function. To begin with, steel angles possess an L-shaped cross-section, featuring two legs positioned perpendicular to one another. The lengths of these legs may differ depending on the application. This L-shaped design offers enhanced stability and strength, making steel angles ideal for load-bearing tasks such as supporting beams or columns. They are commonly employed in constructing frames, braces, and reinforcing structures. On the other hand, steel channels possess a U-shaped cross-section, consisting of a flat bottom and two parallel legs connected by a vertical web. The legs of steel channels are typically tapered or rounded at the edges. The U-shaped design provides excellent resistance to bending and torsion, making steel channels suitable for applications requiring structural support and stability, such as framing systems, support beams, and building facades. Another notable distinction between steel angles and steel channels lies in their weight-bearing capacity. Due to their L-shaped design and shorter legs, steel angles are generally more efficient in carrying vertical loads. Conversely, steel channels, with their wider and more extensive cross-section, are better equipped to handle horizontal loads. Regarding installation, steel angles are typically bolted or welded to other steel members, ensuring a robust connection. Conversely, steel channels can be connected through welding, bolting, or even the use of clips or brackets, depending on the specific application and load requirements. In summary, steel angles and steel channels differ in terms of their cross-sectional shape, weight-bearing capacity, and structural properties. Steel angles are L-shaped and excel in vertical load-bearing applications, while steel channels are U-shaped and are more suitable for horizontal load-bearing tasks. Both shapes offer unique advantages and find widespread use in diverse construction and engineering projects.

- Q: Do steel angles require maintenance?

- Yes, steel angles do require maintenance. While steel is a durable material, it is still susceptible to rust and corrosion, especially when exposed to moisture or harsh environmental conditions. Regular maintenance is necessary to prevent these issues and ensure the longevity of steel angles. Some common maintenance practices include inspecting for any signs of rust or damage, cleaning the surface to remove dirt and debris, and applying protective coatings or paints to prevent corrosion. Additionally, proper storage and handling of steel angles can also contribute to their maintenance. It is important to follow manufacturer guidelines and consult with professionals to determine the specific maintenance requirements for steel angles in different applications.

- Q: Are steel angles affected by creep?

- Yes, steel angles can be affected by creep. Creep is the tendency of a material to deform over time under a constant load or stress. While steel is known for its high strength and durability, it is not completely immune to creep. The extent of creep in steel angles will depend on various factors such as the specific type of steel, the temperature, and the applied load. Creep in steel angles can occur at elevated temperatures or when the load is sustained over a long period. When subjected to high temperatures, the atoms within the steel start to move more rapidly, leading to a gradual deformation of the material. This can be a concern in applications where steel angles are exposed to sustained high temperatures, such as in structural components of industrial furnaces or boilers. Additionally, sustained loads can also cause creep in steel angles. Over time, the constant stress on the material can lead to a slow and progressive deformation. This can be particularly significant in situations where the steel angles are subjected to heavy loads for extended periods, such as in long-span bridges or tall buildings. To mitigate the potential effects of creep, engineers and designers must consider the specific requirements of the application and select the appropriate type of steel angle and design parameters. They may also incorporate additional measures such as providing support or reinforcement to minimize the impact of creep on the structural integrity of the steel angles. Regular inspection and maintenance can also help identify any signs of creep and take necessary measures to address them.

- Q: Can steel angles be used in architectural lighting installations?

- Yes, steel angles can be used in architectural lighting installations. Steel angles provide structural support and can be used to mount lighting fixtures securely. They are often used in applications where durability and strength are important, making them suitable for architectural lighting installations.

- Q: What are the limitations of using steel angles in certain applications?

- There are several limitations to consider when using steel angles in certain applications. Firstly, steel angles may not be suitable for applications that require high strength or load-bearing capacities. While steel angles are generally strong and durable, they may not be able to withstand extremely heavy loads or forces. In such cases, other types of structural steel sections, such as I-beams or hollow sections, may be more appropriate. Secondly, steel angles may not be ideal for applications that require tight tolerances or precise dimensions. Due to the manufacturing process, steel angles can have slight variations in size and shape, which may not be acceptable in certain applications. In these cases, custom-made or precision-machined steel components may be necessary. Furthermore, steel angles may have limitations in terms of corrosion resistance. If the application involves exposure to harsh environments, such as marine or chemical environments, the steel angles may corrode over time. In these situations, alternative materials with better corrosion resistance, such as stainless steel or aluminum, may be more suitable. Lastly, steel angles may not provide the desired aesthetic appearance in certain applications. While steel angles are commonly used in structural and industrial applications, they may not be visually appealing or compatible with architectural or decorative applications. In such cases, alternative materials or finishes may be preferred to achieve the desired aesthetics. Overall, while steel angles have numerous advantages in terms of strength, versatility, and cost-effectiveness, they also have limitations in certain applications. It is essential to carefully assess the specific requirements of the application and consider these limitations before choosing to use steel angles.

- Q: What are the properties of steel angles?

- Steel angles, which are also referred to as angle iron or L-shaped steel, possess numerous qualities that contribute to their extensive use and versatility across various industries. 1. Strength and durability: Solid steel is used to manufacture steel angles, resulting in exceptional strength and durability. These attributes render them suitable for structural applications that demand high strength, such as constructing building frames and supports. 2. Load-bearing capability: The L-shaped design of steel angles enables them to offer excellent load-bearing capacity. They can efficiently distribute weight and provide structural support, making them ideal for the construction of bridges, towers, and other heavy-duty structures. 3. Versatility in applications: The flexibility and adaptability of steel angles allow for their usage in a wide array of applications. They can be easily cut, drilled, and welded, facilitating customization to meet specific project requirements. Commonly employed in the construction, manufacturing, and automotive industries, steel angles showcase their versatility. 4. Resistance to corrosion: Steel angles can be manufactured with corrosion-resistant coatings or can be made from stainless steel. This provides protection against rust and other environmental factors. Thus, they are suitable for outdoor applications and environments with high moisture or chemical exposure. 5. Cost-effectiveness: Comparatively, steel angles are cost-effective when compared to other structural materials like aluminum or wood. They possess a high strength-to-weight ratio, thereby minimizing the amount of material required for a given application. Consequently, steel angles are a cost-efficient choice for various construction projects. 6. Aesthetic appeal: Steel angles can also be utilized for their aesthetic appeal, adding a visually pleasing dimension to architectural designs. They can serve decorative purposes in interior design or as part of ornamental structures, providing both functionality and visual interest. In conclusion, the properties of steel angles, including their strength, load-bearing capacity, versatility, corrosion resistance, cost-effectiveness, and aesthetic appeal, make them an excellent choice for a wide range of applications in different industries.

- Q: Can steel angles be used in conveyor systems?

- Conveyor systems can indeed utilize steel angles. These angles are frequently employed in conveyor systems to provide stability and structural support. They can be employed to establish the framework for the conveyor system, encompassing the conveyor bed, side frames, and supports. Steel angles are renowned for their durability and strength, making them an optimal choice for handling hefty loads and enduring the continual movement and impact encountered by conveyor systems. Furthermore, steel angles can be easily joined through welding or bolting, enabling flexibility in designing and customizing conveyor systems to meet specific requirements. In summary, steel angles are a sought-after option in conveyor system construction due to their dependability, adaptability, and cost-effectiveness.

- Q: Can steel angles be used in agricultural or farming structures?

- Yes, steel angles can be used in agricultural or farming structures. They provide structural support and can be used for framing, bracing, and reinforcing various components such as barns, sheds, and livestock enclosures. Steel angles are durable, versatile, and resistant to weather and pests, making them suitable for use in agricultural environments.

- Q: How do you determine the load capacity of a steel angle?

- The load capacity of a steel angle is determined by calculating its moment of inertia and considering factors such as material strength, dimensions, and the type of loading it will be subjected to. Additionally, engineering standards and codes provide guidelines for determining load capacities based on these calculations.

- Q: What is the maximum length for a steel angle bracket?

- The maximum length for a steel angle bracket can vary depending on the specific design and manufacturer, but it generally ranges from 6 to 12 inches.

Send your message to us

Angle steel GB Q235B 20-250MM hot rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords