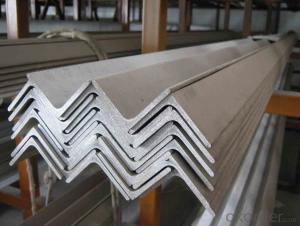

Angle steel High quality hot rolled GB Q235B 20-250MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Angle Steel Details:

| Minimum Order Quantity: | 25mtons | Unit: | m.t. | Loading Port: | China Main Port |

| Supply Ability: | 80000-100000MTS/YEAR | Payment Terms: | TT or LC |

Product Description:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: How do you calculate the moment of resistance for a steel angle?

- To calculate the moment of resistance for a steel angle, you need to consider the properties of the angle section and its dimensions. The moment of resistance is a measure of the ability of the angle to resist bending. The formula to calculate the moment of resistance is: Moment of Resistance = Plastic Section Modulus × Yield Strength of Steel The plastic section modulus can be determined using the following formula: Plastic Section Modulus = (Width × Thickness^2) / 6 In this formula, the width refers to the distance between the outer edges of the angle, and the thickness refers to the thickness of the angle section. The yield strength of the steel is a material property and can be obtained from its specification or reference material. It represents the maximum stress the steel can withstand without permanent deformation. By substituting the values of the plastic section modulus and the yield strength of the steel into the formula for the moment of resistance, you can calculate the value. It is important to note that the dimensions used in the calculations should be in consistent units, such as millimeters or inches, depending on the units used in the yield strength value. This calculation provides an estimate of the moment of resistance for a steel angle and is useful in structural engineering applications to determine the capacity of the angle section under bending loads.

- Q: What are the common welding techniques for steel angles?

- There are several common welding techniques that can be used for steel angles: 1. Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a popular choice. It involves using a consumable electrode coated in flux, which creates a protective shield around the weld pool. SMAW is versatile and can be used for steel angles of various thicknesses. 2. Gas Metal Arc Welding (GMAW), also known as MIG welding, is another technique that uses a continuous wire electrode and a shielding gas, typically a mixture of argon and carbon dioxide. GMAW allows for high welding speeds and provides good control over the weld pool, making it suitable for steel angles. 3. Flux-Cored Arc Welding (FCAW) is similar to GMAW, but instead of a shielding gas, it utilizes a flux-filled wire. When heated, the flux creates a protective gas shield that prevents contamination of the weld. FCAW is especially useful for outdoor welding or in windy conditions. 4. Gas Tungsten Arc Welding (GTAW), also known as TIG welding, is a precise and clean welding process. It uses a non-consumable tungsten electrode and a shielding gas, usually argon. GTAW produces high-quality welds on steel angles, making it a preferred choice for thin angles or when aesthetics and control are important. 5. Submerged Arc Welding (SAW) is a semi-automatic or automatic welding process that involves feeding a continuous wire electrode and a granular flux into the weld zone. The flux covers the weld, preventing atmospheric contamination. SAW is commonly used for thicker steel angles and provides high deposition rates. It is crucial to select the appropriate welding technique based on the specific requirements of the steel angle joint, such as thickness, joint design, and desired weld quality. Additionally, proper preparation, including cleaning and preheating if necessary, is essential to ensure successful welds on steel angles.

- Q: Can steel angles be used in seismic applications?

- Yes, steel angles can be used in seismic applications. Steel angles are commonly used in seismic applications due to their high strength and ductility properties. They are often used in the construction of steel moment frames and bracing systems, which are designed to resist lateral forces caused by seismic events. Steel angles are particularly effective in providing structural support and stability in areas prone to earthquakes. They can be used as diagonal braces, gusset plates, or stiffeners to enhance the seismic performance of buildings and structures. Additionally, steel angles can be easily fabricated and installed, making them a cost-effective choice for seismic applications.

- Q: Are steel angles suitable for mezzanine floor construction?

- Yes, steel angles are suitable for mezzanine floor construction. Steel angles are commonly used in mezzanine floor construction due to their structural strength and durability. They provide excellent support and stability, making them an ideal choice for supporting the weight of the mezzanine floor and any loads placed on it. Steel angles can be easily bolted or welded together to create a strong framework for the mezzanine floor. Additionally, steel angles can be customized to fit specific design requirements, allowing for flexibility in mezzanine floor construction. Overall, steel angles are a reliable and cost-effective solution for mezzanine floor construction.

- Q: Can steel angles be used for staircases or handrails?

- Staircases and handrails can indeed utilize steel angles. These angles, known for their resilience and durability, are highly versatile and frequently employed in construction. Regarding staircases, steel angles can serve as stringers, delivering stability and supporting the steps. Furthermore, they can function as handrails, providing a reliable grip and aiding individuals utilizing the staircase. By welding or bolting steel angles in place, one can ensure a secure and enduring installation for staircases and handrails. Moreover, steel angles can be tailored to meet specific design prerequisites, enabling the creation of visually appealing and practical staircases and handrails with flexibility.

- Q: How do you determine the center of gravity for a steel angle?

- To determine the center of gravity for a steel angle, you need to consider its shape and dimensions. The center of gravity is the point where the weight of the object is evenly distributed, and finding this point is crucial for understanding its stability and balance. First, measure the length, width, and thickness of the steel angle. These measurements will help you calculate the area and volume of the angle, which are essential for determining the center of gravity. Next, locate the centroid of the steel angle. The centroid is the geometric center of the object, and it represents the point where all the weight is concentrated. For a symmetrical steel angle, the centroid will be at the intersection of the two axes of symmetry. However, if the angle is asymmetrical, finding the centroid might require more complex calculations. To calculate the centroid, use the formulas for the area moment of inertia. These formulas depend on the shape of the angle. For example, if the angle is a simple L-shape, the centroid can be determined by finding the average of the coordinates of the two legs' centroids. Once you have determined the centroid, you can then locate the center of gravity. The center of gravity coincides with the centroid of the steel angle in uniform density objects. However, for objects with non-uniform density, additional calculations might be required to account for variations in weight distribution. In summary, determining the center of gravity for a steel angle involves measuring its dimensions, calculating the centroid based on its shape, and then locating the center of gravity. This information is crucial for understanding the angle's stability and balance, especially in applications where it will be subjected to external forces or loads.

- Q: Can steel angles be used in HVAC ductwork?

- HVAC ductwork can indeed make use of steel angles. To ensure structural support and reinforcement, ductwork often incorporates steel angles. These angles are frequently employed at corners and joints, reinforcing the ductwork and preserving its shape. Thanks to their durability, strength, and resistance to corrosion, steel angles are highly suitable for use in HVAC ductwork systems. Moreover, their easy weldability and ability to be fastened together allow for effortless installation and customization. Consequently, steel angles serve as a dependable and frequently utilized element within HVAC ductwork systems.

- Q: What is the cost of steel angles compared to other structural materials?

- The cost of steel angles compared to other structural materials can vary depending on factors such as the specific type of material, market conditions, and quantity needed. However, generally speaking, steel angles tend to be a cost-effective choice for structural applications due to their durability, strength, and versatility.

- Q: Are steel angles available in custom sizes?

- Yes, steel angles are available in custom sizes.

- Q: Can steel angles be used in playground or recreational equipment?

- Yes, steel angles can be used in playground or recreational equipment. Steel angles provide structural support and stability, making them suitable for constructing various elements of playground equipment such as swing sets, climbing frames, and slides.

Send your message to us

Angle steel High quality hot rolled GB Q235B 20-250MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords