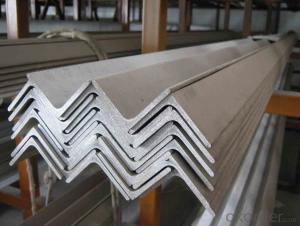

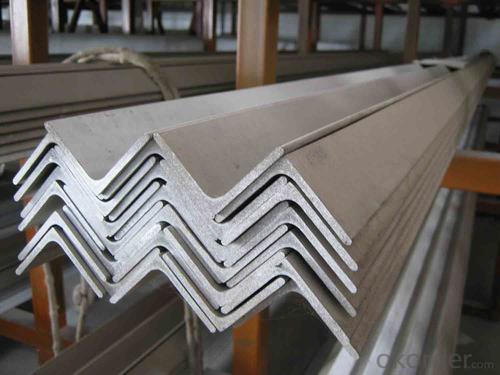

Angle steel GB Q235B high quality 20-250MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Angle Steel Details:

| Minimum Order Quantity: | 25mtons | Unit: | m.t. | Loading Port: | China Main Port |

| Supply Ability: | 80000-100000MTS/YEAR | Payment Terms: | TT or LC |

Product Description:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel angles be used in solar panel mounting systems?

- Yes, steel angles can be used in solar panel mounting systems. Steel angles are often chosen for their strength, durability, and stability, making them suitable for supporting the weight of solar panels. They can be easily fabricated and customized to fit specific project requirements. Additionally, steel angles provide a stable base for solar panels, ensuring proper alignment and reducing the risk of damage due to wind or other external factors. However, it is important to consider the specific requirements of the solar panel system and consult with a structural engineer or a professional installer to ensure that the chosen steel angles meet the necessary load-bearing capacity and structural integrity standards.

- Q: Can steel angles be painted or finished for decorative purposes?

- Indeed, steel angles have the potential to be painted or finished in order to achieve decorative purposes. These steel angles, commonly utilized in construction and industrial settings, can undergo painting or finishing procedures to enhance their visual appeal and contribute a decorative element. The act of painting steel angles serves the dual purpose of safeguarding them against corrosion and rust, while also allowing for customization to align with the aesthetic requirements of the particular project. Furthermore, alternative finishes such as powder coating, electroplating, or galvanizing can be employed to augment both the appearance and durability of these steel angles. Through the application of paint or finishing techniques, steel angles can be seamlessly integrated into a variety of architectural and design ventures, thereby serving both functional and visually enticing purposes.

- Q: Are steel angles suitable for bridge construction?

- Indeed, steel angles are indeed suitable for the construction of bridges. Their versatility, strength, and cost-effectiveness make them a popular choice in bridge construction. They can be easily fabricated and play a crucial role in supporting various bridge components such as beams, trusses, and connections. With their impressive load-bearing capacity, steel angles can withstand heavy loads and forces, making them an ideal choice for bridge construction where durability and resilience are paramount. Furthermore, the ability to weld or bolt steel angles together allows for efficient and speedy construction and modification. In summary, steel angles are a dependable and widely used element in bridge construction, contributing significantly to the strength, stability, and longevity of bridges.

- Q: What are the different methods of surface powder coating for steel angles?

- Surface powder coating for steel angles can be achieved through various methods, each serving the purpose of providing protection and enhancing aesthetics. 1. One commonly used technique is electrostatic spraying, where a specialized spray gun is employed to apply the powder coating onto the steel surface. The powder particles, carrying a positive charge, are drawn towards the grounded steel angle, ensuring a uniform and even coating. 2. Another approach is the fluidized bed method. Here, the steel angles are heated and then immersed in a bed of fluidized powder particles. As the steel's heat causes the powder particles to melt, they adhere to the surface, resulting in a smooth and durable coating. 3. The powder coating booth method involves placing the steel angles within a designated booth. Equipped with a powder spray gun, the booth emits a fine mist of powder coating onto the surface. The angles are subsequently cured in an oven to bond and melt the powder particles, creating a robust and long-lasting coating. 4. Combining the advantages of electrostatic spraying and fluidized bed techniques, the electrostatic fluidized bed method offers a more controlled and consistent coating. Preheated steel angles are dipped into a fluidized bed of powder particles while an electrostatic charge is applied, ensuring a uniform application. 5. Tribocharging is an alternative technique where frictional charging is used to apply the powder coating. The powder particles pass through a tribocharging gun, obtaining a positive charge. Subsequently, these charged particles are attracted to the grounded steel angle, resulting in a high-quality and consistently applied coating. Each method possesses its own distinct advantages and suitability for specific applications. The choice of coating approach depends on factors such as desired finish, coating thickness, production volume, and cost considerations.

- Q: How do steel angles contribute to the overall sustainability of a building?

- A building's overall sustainability is enhanced by steel angles in various ways. To begin with, steel angles are constructed from recycled materials, making them a sustainable choice for building purposes. Steel is one of the world's most recycled materials, boasting a high recycling rate. This reduces the necessity for new resources and lessens the environmental impact of extraction and production. Additionally, steel angles offer structural efficiency, enabling them to support greater loads with less material compared to other building materials. This efficiency reduces the amount of steel needed for construction, minimizing the carbon footprint associated with steel production and transportation. Furthermore, steel angles are extremely durable and long-lasting. They possess high resistance to corrosion, fire, and pests, thereby reducing the maintenance and replacement requirements over the building's lifespan. This durability results in reduced waste generation and lower life-cycle costs, ultimately making the building more sustainable in the long term. Moreover, steel angles are versatile and easily reusable or repurposed. In the event of renovation or demolition, salvaging and reusing the steel angles in other construction projects is feasible. This promotes a circular economy approach, minimizing waste generation and contributing to the overall sustainability of the construction industry. Lastly, steel angles possess excellent thermal properties that can enhance a building's energy efficiency. They can be utilized as part of the building envelope, aiding in the reduction of energy consumption for heating and cooling. By improving insulation and airtightness, steel angles contribute to lower energy demand and reduced greenhouse gas emissions. In conclusion, steel angles contribute to a building's overall sustainability through their recycled content, structural efficiency, durability, recyclability, and energy-saving properties. Opting for steel angles in construction allows for resource conservation, waste reduction, and a minimized environmental impact in the built environment.

- Q: How can the angle iron tripod be welded or not?

- Angle called angle, the steel strip is perpendicular to each other on both sides into the corner. There are equal angles and unequal angles. The two sides of an equal angle steel are equal in width.

- Q: Can steel angles be used in seismic zones?

- Yes, steel angles can be used in seismic zones. Steel angles are commonly used in seismic design and construction as they provide structural support and stability. However, it is important to ensure that the steel angles are designed and installed according to the specific building codes and regulations for seismic zones to ensure their effectiveness and safety.

- Q: What are the advantages of using steel angles in construction?

- There are several advantages of using steel angles in construction. Firstly, steel angles provide excellent structural support and stability, making them ideal for supporting heavy loads and resisting bending or twisting forces. Secondly, steel angles are highly versatile and can be easily customized to fit specific design requirements. They can be cut, drilled, welded, or bolted together, allowing for flexible and efficient construction. Additionally, steel angles have high durability and corrosion resistance, ensuring long-lasting performance and minimal maintenance. Finally, steel angles offer cost-effectiveness as they are relatively inexpensive compared to other construction materials, making them a popular choice in various construction projects.

- Q: What are the different types of steel angles used in architectural applications?

- There are several types of steel angles commonly used in architectural applications, including equal angles, unequal angles, L-shaped angles, and T-shaped angles. These angles are used to provide structural support, enhance aesthetics, and create unique design features in buildings.

- Q: Are steel angles suitable for agricultural applications?

- Yes, steel angles are suitable for agricultural applications. They are commonly used in the construction of agricultural buildings, fences, and equipment due to their strength, durability, and versatility. Steel angles provide stability and support, making them ideal for various agricultural tasks such as framing structures, reinforcing corners, or creating sturdy connections.

Send your message to us

Angle steel GB Q235B high quality 20-250MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords