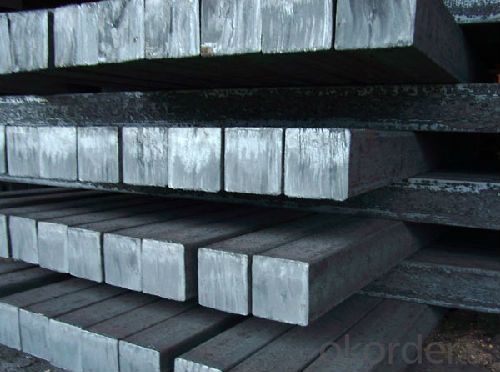

Hot Rolled Steel Billet Make in China for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Billet Make in China for Sale with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Billet Make in China for Sale are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Billet Make in China for Sale are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Packaging & Delivery:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: How are steel billets inspected for internal defects?

- Various non-destructive testing (NDT) techniques are utilized to inspect steel billets for internal defects. Ultrasonic testing (UT) is a common method wherein high-frequency sound waves are employed to detect flaws within the billet. By sending ultrasonic waves into the billet and analyzing the reflected waves, any internal flaws can be identified. UT has the capability to detect defects such as cracks, voids, inclusions, and other irregularities. Another technique used is magnetic particle inspection (MPI), which is particularly effective for identifying surface and near-surface defects in ferromagnetic materials like steel. By applying a magnetic field to the billet and spreading iron particles over its surface, any defects will cause the particles to form visible indications, thereby providing a clear indication of internal flaws. Liquid penetrant testing (PT) is another widely employed method for inspecting steel billets. This process involves applying a liquid dye to the billet's surface and allowing it to penetrate any surface-breaking defects. After a designated time, excess dye is removed and a developer is applied. The developer draws out the penetrant from any defects, making them visible under suitable lighting conditions. Furthermore, radiographic testing (RT) can be utilized to detect internal defects in steel billets. This method utilizes X-rays or gamma rays to capture images of the billet's internal structure. As the radiation passes through the billet, a film or digital detector records the transmitted radiation. Any internal defects will appear as shadows on the image, facilitating their identification. In summary, a combination of these NDT techniques is often employed to ensure a comprehensive inspection of steel billets for internal defects. This aids in maintaining the quality and integrity of the billets, ensuring they meet the necessary specifications and standards.

- Q: How are steel billets used in the manufacturing of tooling?

- Steel billets are an essential component in the manufacturing of tooling. Tooling refers to the process of designing and creating tools that are used in various industries for cutting, shaping, or forming materials. Steel billets are semi-finished products that are cast from molten steel and then hot rolled into various shapes and sizes. In the manufacturing of tooling, steel billets serve as the raw material from which the tool is formed. These billets are usually made from high-quality steel alloys that exhibit excellent strength, durability, and wear resistance properties. These characteristics are crucial for tooling applications as they ensure the longevity and performance of the tools. Once the steel billets are obtained, they undergo a series of processes to transform them into tooling components. The first step is to heat the billets to a specific temperature, typically above the recrystallization temperature, which makes the steel more malleable and easier to shape. This process is known as hot working. After heating, the steel billets are shaped into the desired form through various techniques such as forging, extrusion, or rolling. These methods allow the steel to be molded into complex shapes, such as dies or molds, which are commonly used in tooling applications. The shaping process ensures that the tooling components have the necessary dimensions, surface finish, and structural integrity to perform their intended function. Once the tooling components are shaped, they may undergo additional heat treatments to further enhance their mechanical properties. Processes like tempering, annealing, or hardening are commonly used to modify the steel's hardness, toughness, and resistance to wear. These treatments increase the tooling's lifespan and improve its performance in demanding manufacturing environments. Overall, steel billets play a crucial role in the manufacturing of tooling by serving as the starting material for shaping tooling components. The high-quality steel used in billets provides the necessary strength and durability required for tooling applications. By shaping, heat treating, and finishing these billets, manufacturers can create tooling that meets the specific needs of various industries, enabling efficient and precise cutting, shaping, and forming of materials.

- Q: What are the potential applications of steel billets in the agricultural aftermarket?

- Steel billets have a wide range of potential applications in the agricultural aftermarket. One of the key uses of steel billets in this industry is for the manufacturing of agricultural machinery and equipment. Steel billets are commonly used to fabricate components such as plows, cultivators, seeders, and harvesting equipment. The agricultural industry requires durable and robust machinery that can withstand the harsh conditions of farming operations. Steel billets provide the necessary strength and toughness to withstand the demanding tasks involved in agriculture, such as tilling the soil or harvesting crops. The high-strength properties of steel billets make them ideal for withstanding heavy loads and rough terrain. Additionally, steel billets can be used for constructing storage and handling structures in the agricultural sector. Steel buildings and structures are highly resistant to weathering, pests, and fire, making them suitable for storing grain, livestock, and other agricultural products. Steel billets can be used to fabricate the main framework of these structures, ensuring their durability and longevity. Another potential application of steel billets in the agricultural aftermarket is for the production of fencing and livestock handling equipment. Steel fencing is commonly used in agricultural settings to secure boundaries, contain livestock, and protect crops from animals. Steel billets can be shaped and welded to create strong and reliable fencing materials that can withstand the test of time. Furthermore, steel billets can be utilized in the manufacturing of irrigation systems and water management equipment. Agricultural operations often require efficient irrigation systems to ensure proper water distribution to crops. Steel billets can be used to fabricate pipes, valves, and other components that are critical for irrigation systems, providing a durable and long-lasting solution. In summary, steel billets have numerous potential applications in the agricultural aftermarket. From manufacturing machinery and equipment to constructing storage structures, fencing, and irrigation systems, steel billets offer the strength, durability, and reliability required in the demanding agricultural industry.

- Q: How are steel billets used in the production of steel cables?

- Steel billets are used in the production of steel cables by being heated and then passed through a series of rollers to shape them into thin, long strands. These strands are then twisted together to form the cables, which are used for various applications such as suspension bridges, elevators, and construction projects. The high strength and durability of steel billets make them ideal for producing strong and reliable steel cables.

- Q: How are steel billets used in the manufacturing of medical equipment?

- Steel billets are used in the manufacturing of medical equipment as a raw material that can be shaped and machined into various components such as surgical instruments, implants, and medical device casings. The high strength and durability of steel make it suitable for producing equipment that requires precision, reliability, and resistance to corrosion.

- Q: How are steel billets manufactured?

- Steel billets are manufactured through a process called continuous casting, which is the most common method used in the steel industry. This process involves pouring molten steel into a water-cooled mold, where it solidifies and takes the shape of a rectangular or square cross-section. The molten steel is typically obtained from a steelmaking furnace, such as a basic oxygen furnace or an electric arc furnace. Before the casting process begins, the mold is preheated to prevent the molten steel from solidifying prematurely. Once the mold is ready, the molten steel is poured into it through a ladle or a tundish, which helps control the flow of the liquid steel and removes impurities. As the molten steel enters the mold, it starts to cool rapidly due to the water-cooled walls of the mold. This rapid cooling leads to the solidification of the outer layer of the steel, forming a solid shell. The cooling process continues as the steel moves through the length of the mold, with water being sprayed on it to accelerate solidification. Once the solidified steel reaches the end of the mold, it is cut into desired lengths using a cutting torch or a mechanical shear. These solidified steel pieces, known as billets, are then transferred to a cooling bed or a roller table, where they continue to cool and solidify further. After sufficient cooling, the billets are inspected for any surface defects or other irregularities. Depending on the quality requirements, the billets may undergo further processing, such as heat treatment or surface conditioning, to improve their mechanical properties and surface finish. Overall, the continuous casting process allows for the efficient and cost-effective production of steel billets, which serve as a crucial raw material for various downstream steel products, such as bars, rods, and wire rods.

- Q: What are the factors that affect the mechanical properties of steel billets?

- There are several factors that affect the mechanical properties of steel billets. 1. Chemical composition: The chemical composition of steel, including the levels of carbon, manganese, silicon, and other alloying elements, plays a significant role in determining its mechanical properties. These elements affect the strength, hardness, and ductility of the steel billets. 2. Heat treatment: The heat treatment process, including the temperature and duration of heating and cooling, can greatly influence the mechanical properties of steel billets. Heat treatment techniques such as annealing, quenching, and tempering can be used to enhance the hardness, toughness, and overall strength of the steel. 3. Microstructure: The microstructure of steel, which is determined by factors such as cooling rate and alloying elements, greatly influences its mechanical properties. The presence of different phases, such as ferrite, pearlite, and martensite, affects the strength, ductility, and toughness of the steel billets. 4. Grain size: The size and distribution of grains in the steel billets can impact their mechanical properties. Finer grain sizes are generally associated with improved strength and toughness, while larger grain sizes may result in reduced mechanical properties. 5. Processing conditions: The processing conditions during the production of steel billets, such as the temperature and rate of deformation, can affect their mechanical properties. Factors such as rolling, forging, and extrusion can influence the grain structure and overall mechanical behavior of the steel. 6. Surface condition: The surface condition of steel billets, including the presence of defects such as cracks, voids, or surface contamination, can have a significant impact on their mechanical properties. Surface defects can act as stress concentration points and reduce the overall strength and integrity of the steel. 7. Environmental factors: Environmental conditions, such as temperature, humidity, and exposure to corrosive substances, can affect the mechanical properties of steel billets. Corrosion can lead to reduced strength and structural integrity, while high temperatures can cause softening or thermal degradation of the steel. It is important to consider these factors when designing and manufacturing steel billets to ensure that the desired mechanical properties are achieved for specific applications.

- Q: How are steel billets used in the manufacturing of bearings?

- Steel billets are an essential raw material used in the manufacturing of bearings. Bearings are mechanical components that facilitate smooth rotational or linear movement between two parts. Steel billets, which are solid blocks of steel, are first heated and then subjected to a forging process to shape them into the desired dimensions and form. This process involves applying high pressure to the heated billets, which results in plastic deformation and the creation of a rough bearing shape. After the initial forging, the rough-shaped billets undergo further precision machining processes to refine their dimensions and improve their surface finish. These processes include turning, grinding, and polishing, which ensure the final product meets the required specifications for bearing performance. Once the billets are machined to the appropriate size and shape, they are heat-treated to enhance their mechanical properties. Heat treatment involves subjecting the billets to specific temperatures and durations to achieve desired hardness, strength, and durability. This process can include steps such as quenching, tempering, and annealing, depending on the desired characteristics of the bearing. After heat treatment, the steel billets are ready for the final step in the bearing manufacturing process: assembly. The billets are inspected for any defects or imperfections and then assembled with other bearing components, such as inner and outer rings, rolling elements, and cages. These components are carefully matched and assembled to achieve the desired performance and load-carrying capacity of the bearing. In conclusion, steel billets play a crucial role in the manufacturing of bearings. They are initially forged into a rough bearing shape, then machined, heat-treated, and finally assembled with other components to create a high-quality bearing that can withstand various loads and provide smooth movement in a wide range of applications.

- Q: What are the potential applications of steel billets in the food and beverage sector?

- Steel billets have a variety of potential applications in the food and beverage sector due to their strength, durability, and hygienic properties. These billets can be used to manufacture equipment such as food processing machinery, storage tanks, and transportation containers, ensuring safe and efficient handling of food and beverages. Additionally, steel billets can be utilized in the construction of commercial kitchen infrastructure, providing a strong and reliable foundation for food preparation areas.

- Q: What are the weight ranges of steel billets?

- The weight ranges of steel billets can vary depending on the specific requirements and industry standards. However, commonly used weight ranges for steel billets are typically between 1,000 kilograms (2,204 pounds) to 5,000 kilograms (11,023 pounds).

Send your message to us

Hot Rolled Steel Billet Make in China for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords