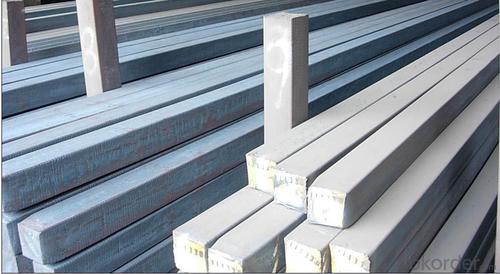

Square Steel Billet Q235 Grade Prime Quality 8#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Square Steel Billet Q235 Grade Prime Quality 8#

M. S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Main Feature Square Steel Billet Q235 Grade Prime Quality 8#

Raw elements(C,Fe,Ni,Mn,Cr,Cu.)---Smelted ingots by AOD finery---hot rolled into black suface---pickling in acid liquid---cold drawn----polished by automatically machine--- cutting into pieces---checking quanlity

Applications of Square Steel Billet Q235 Grade Prime Quality 8#

Widely Used in the areas such as Stainless Steel Fasteners, Chains, Kitchen and Sanitary wares, Furniture handles, Handrails, Electroplating and Electrolyzing pendants, Foods, Electron, Petroleum, Construction and Decoration, etc. Products have a high strength after cold-working. Electronic products parts, Medical appliance, Springs, Bus Inside and Outside packaging and building, Street Lamp Posts, etc. Decoration materials and Outdoor Publicity Billboard. Used for the products which have the Anti-Stress Corrosion requirement. Electron Products, Table-wares, Bolts, Nuts, Screen Meshes, Cumbustors and so on.

Specifications of Square Steel Billet Q235 Grade Prime Quality 8#

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

FAQ of Square Steel Billet Q235 Grade Prime Quality 8#

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How long do steel billets last?

- The lifespan of steel billets can vary depending on various factors such as the quality of the steel, storage conditions, and usage. Generally, steel billets can last for decades if stored properly and used within their recommended lifespan.

- Q: Can steel billets be forged?

- Yes, steel billets can be forged. Forging is a common method used to shape metals into desired forms by applying compressive forces. Steel billets, which are semi-finished products in the form of rectangular bars, can undergo forging to transform them into various shapes such as bars, plates, or complex geometries. During the forging process, the steel billets are heated to a specific temperature to make them malleable, and then they are subjected to mechanical forces using hammers, presses, or other forging equipment. This enables the billets to be shaped and compressed, thereby improving their mechanical properties and imparting specific characteristics to meet desired requirements. Overall, forging steel billets is an important process in the production of various metal components and products.

- Q: How are steel billets used in the production of machined parts?

- Steel billets are an essential raw material in the production of machined parts. They are typically used as the starting point for creating various components and products through machining processes such as turning, milling, drilling, and grinding. Firstly, steel billets are heated to a specific temperature to make them more malleable. This process, known as forging, allows the billets to be shaped and manipulated into the desired form. The heated billets are then placed onto a cutting machine, where they are cut into smaller sections called blanks or workpieces. After the billets have been cut, the blanks are further processed using different machining techniques. For example, turning involves rotating the workpiece while removing excess material with cutting tools to create cylindrical shapes like shafts or rods. Milling involves using rotary cutters to remove material from the workpiece, typically to create complex shapes or features. Drilling is another common machining process where holes are created in the billet or workpiece using a drill bit. This is often required to accommodate screws, bolts, or other fasteners in the final product. Grinding, on the other hand, is used to achieve a smooth and precise surface finish on the machined parts. Overall, steel billets play a crucial role in the production of machined parts. They provide a solid and durable foundation that can be shaped and transformed into various components through the application of different machining techniques. Without steel billets, the manufacturing of machined parts would not be possible, as they serve as the starting point for creating the final products that we use in numerous industries.

- Q: How are steel billets inspected for surface finish?

- Steel billets are inspected for surface finish using different methods and techniques to ensure quality and compliance with industry standards. One common method is visual inspection, where trained inspectors visually examine the surface of the billet for any defects such as scratches, pits, cracks, or any other irregularities. This inspection is typically done under proper lighting conditions to enhance the visibility of any imperfections. Another method used is non-destructive testing (NDT), which includes techniques such as magnetic particle inspection (MPI) and liquid penetrant inspection (LPI). MPI involves applying a magnetic field to the billet and then applying a magnetic particle suspension that will reveal any surface defects by adhering to them. LPI, on the other hand, involves applying a liquid penetrant solution to the surface of the billet, which is then removed and followed by the application of a developer that highlights any defects. Ultrasonic testing (UT) is another commonly used technique for inspecting the surface finish of steel billets. UT utilizes high-frequency sound waves that are transmitted through the billet, and any reflected waves are analyzed to detect any surface or subsurface defects. This method can provide detailed information about the surface condition and can detect even minute flaws. In addition to these methods, surface profilometers can be used to measure the roughness of the billet's surface. These devices use a stylus or laser to measure the height variations on the surface, providing data on the roughness and texture. Overall, steel billets undergo thorough inspection for surface finish using a combination of visual inspection, NDT techniques, and surface profilometry. These inspections help ensure that the billets meet the required surface finish standards and are suitable for further processing or manufacturing.

- Q: What are the different types of surface finish methods used for steel billets?

- Steel billets can be subjected to various surface finish methods, each serving unique purposes and achieving distinct surface characteristics. These methods encompass: 1. Hot rolling: By passing the steel billet through heated rollers, the material is compressed and shaped, resulting in a smooth and glossy surface finish. 2. Shot blasting: This technique involves propelling small metallic or non-metallic particles at high speeds onto the steel billet's surface. It effectively eliminates scale, rust, or contaminants, leaving behind a clean and textured finish. 3. Pickling: Through immersion in an acid solution, the steel billet undergoes a chemical process that eliminates oxide scale and surface impurities. This method provides a smooth and corrosion-resistant surface finish. 4. Grinding: By employing abrasive wheels or belts, material is removed from the steel billet's surface. This process enables the attainment of a precise and smooth finish suitable for various applications. 5. Polishing: Utilizing abrasive materials, imperfections or roughness are eliminated from the steel billet's surface through mechanical polishing. This method yields a high-gloss, mirror-like finish. 6. Cold rolling: Similar to hot rolling, cold rolling entails passing the steel billet through rollers. However, the billet remains unheated during this process, resulting in a smoother and more precise surface finish. 7. Coating: This surface finish method involves applying a protective layer or coating onto the steel billet. It can encompass paints, varnishes, or specialized coatings aimed at enhancing the steel billet's appearance, durability, or corrosion resistance. Each of these surface finish methods possesses distinct advantages and is selected based on the desired application, aesthetics, and functional requirements of the steel billet.

- Q: What are the different types of steel billet casting methods?

- There are several different types of steel billet casting methods, including continuous casting, centrifugal casting, and ingot casting. Continuous casting involves the continuous pouring of molten steel into a water-cooled mold, resulting in a continuous solidified billet. Centrifugal casting utilizes centrifugal force to pour the molten steel into a rotating mold, creating a cylindrical billet. Ingot casting involves pouring molten steel into a stationary mold to create a solidified ingot shape, which is then further processed into billets.

- Q: What are the main factors affecting the corrosion resistance of carbon steel billets?

- Several primary factors influence the corrosion resistance of carbon steel billets. 1. Composition: The composition of carbon steel billets plays a vital role in determining their resistance to corrosion. Certain alloying elements, such as chromium, nickel, and copper, can enhance their corrosion resistance by forming a protective layer on the steel surface and preventing the formation of rust or other corrosive products. 2. Environmental conditions: The corrosion resistance of carbon steel billets is also influenced by the environment in which they are exposed. Factors like humidity, temperature, pH level, and the presence of corrosive substances like acids or salts can accelerate the corrosion process. For example, high humidity and acidic conditions can increase the rate of corrosion. 3. Surface condition: The condition of the carbon steel billet's surface is crucial for its corrosion resistance. Any imperfections, scratches, or roughness on the surface can serve as initiation sites for corrosion. To minimize the chances of corrosion, it is essential to maintain a smooth and clean surface. 4. Protective coatings: The application of protective coatings, such as paints, varnishes, or corrosion inhibitors, can significantly enhance the corrosion resistance of carbon steel billets. These coatings act as a barrier between the steel surface and the corrosive environment, thereby reducing direct contact and slowing down the corrosion rate. 5. Galvanic corrosion: Carbon steel billets can experience galvanic corrosion when they come into contact with dissimilar metals or alloys in the presence of an electrolyte. The difference in electrical potential between the metals creates a galvanic cell, leading to accelerated corrosion of the less noble metal (carbon steel). Proper insulation or the use of sacrificial anodes can help mitigate galvanic corrosion. In conclusion, the corrosion resistance of carbon steel billets is influenced by factors such as composition, environmental conditions, surface condition, protective coatings, and the possibility of galvanic corrosion. By taking these factors into account and implementing appropriate measures, the corrosion resistance of carbon steel billets can be effectively improved.

- Q: What is the average price of steel billets?

- The average cost of steel billets may vary due to various factors such as market conditions, supply and demand dynamics, and the grade and quality of the billets. It is crucial to acknowledge that global economic influences, such as raw material expenses, energy prices, and trade policies, can cause fluctuations in the average price. To obtain an accurate understanding of the average steel billet price, it is advisable to consult industry reports, trade publications, and market analysis platforms that offer updated information on steel prices. Additionally, seeking advice from steel suppliers and manufacturers or engaging in negotiations with multiple sources can aid in determining the prevalent average price within a specific region or market.

- Q: What are the main factors affecting the hardness of steel billets?

- The hardness of steel billets is primarily determined by various factors. Firstly, the carbon content plays a vital role in determining steel hardness. Higher carbon content leads to increased hardness as carbon atoms occupy spaces between iron crystals, forming stronger bonds and enhancing material resistance to deformation. Secondly, the inclusion of alloying elements significantly affects steel hardness. Elements like chromium, molybdenum, and vanadium create solid solutions with iron, altering its crystal structure and strengthening the material. These elements facilitate the formation of fine and uniform microstructures, resulting in higher hardness. The heat treatment process is another crucial factor that impacts steel billet hardness. Controlled heating and rapid cooling, such as quenching and tempering, cause a transformation in the crystal structure of steel. This transformation, known as martensitic transformation, increases hardness by generating a high concentration of dislocations and reducing grain size. Furthermore, the cooling rate during solidification also affects steel billet hardness. Rapid cooling, like water quenching, promotes the formation of a fine microstructure and enhances hardness. Conversely, slower cooling rates allow for the growth of larger grains, leading to reduced hardness. Lastly, the presence of impurities and non-metallic inclusions can adversely affect steel billet hardness. These impurities disrupt the crystal lattice, reducing material strength and hardness. Therefore, the purity and cleanliness of the steel composition are crucial for achieving higher hardness levels. In conclusion, several factors, including carbon content, alloying elements, heat treatment processes, cooling rate, and the presence of impurities, influence the hardness of steel billets. To attain the desired hardness properties, it is essential to comprehend and control these factors.

- Q: Difference between billet, slab and billet

- Steel billet is a product made by steel-making furnace by casting. The billet can be divided into two kinds from the manufacturing process, mould blank and continuous casting billet. At present, the casting process has been basically eliminated. The classification is mainly divided into two kinds: slab: large cross section, high ratio, mainly used for rolling plate. Billet: cross section width, height equal, or difference is not big, mainly used for rolling steel, wire. Use billet is steel, through processing can be used as mechanical parts, forgings, processing all kinds of steel, steel, Q345B, channel steel, wire is the role of billet. Billet is used for the production of semi-finished steel products, generally can not be used directly for society. Billet and steel are strictly divided into standard, and can not be determined by the final product of the enterprise, but should be carried out according to the uniform standard of the whole society. Usually, billet and steel is relatively easy to distinguish, but for some billets, with the same specification and the same purpose (such as rolling and steel tube), whether for other industries by use, whether through steel processing process, whether after finishing mill processing to distinguish. Continuous cast steel square and rectangular billets are mainly made of plain carbon steel, low carbon and low silicon cold rolled material, high quality carbon structural steel, low alloy high strength steel, special steel and so on.

Send your message to us

Square Steel Billet Q235 Grade Prime Quality 8#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords