Hot Rolled Steel Billet China Supplier/Made In China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

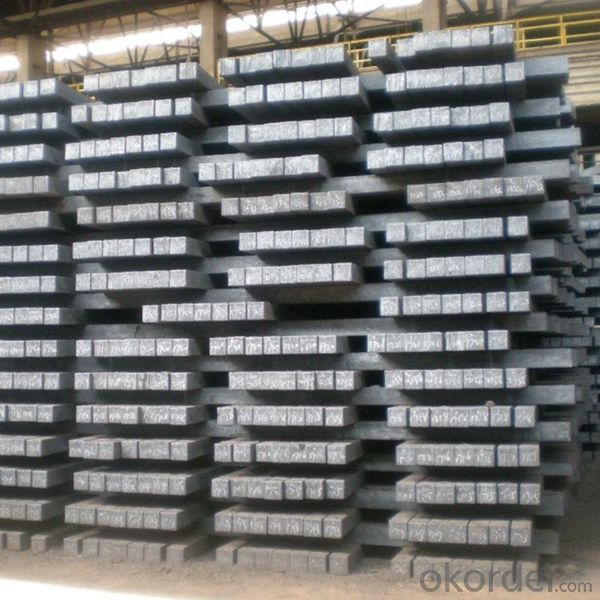

1. Product picture:

2. Production Equipment

Currently the main equipment:

1, two section of new environmental protection gas occurrence furnace two.

2, digital temperature control of high efficiency and energy saving heating furnace.

3, 650 continuous rolling mill bearing.

4, natural cooling bed.

5, modern product collecting and bundling equipment.

6, electrical control of the use of the German Siemens products.

3. Production Description

Owing to the bearing of domestic advanced technology of continuous mill, natural cooling bed and the advanced electric control equipment, so that the company's products than water cooling products in quality are greatly improved, product size precision of the company, minus tolerance of high control precision, quality and stable performance, is not easy to rust, appearance and color pure and beautiful. And rolling speed, high output, consumption and low cost, has the very high prestige both at home and abroad.

2013 February to transform the original steel production line, the electric control system of rolling mill was updated, increased the number of rolling mill heating furnace, improves the cooling capacity, etc..

Company's annual output of 800000 tons. Main products are GB No. 10 -30 channel, American Standard Japanese standard channel and strip etc..

4. Why Choose Us?

We are professional in products export.

We have established longterm cooperation with forwarders and shipping company.

We have more than twenty overseas houseware with timely aftersale service.

We have complicate and professional quality control system, from material purchasing to products loading abroad.

- Q: What are the challenges and innovations in the steel product manufacturing industry?

- The steel product manufacturing industry faces various challenges and innovations. One significant challenge is the increasing demand for sustainability and environmental responsibility. Companies are required to adopt greener manufacturing processes, reduce carbon emissions, and minimize waste. Innovations in this area include the development of more efficient energy usage and the use of recycled materials. Another challenge is the need for cost-effective production while maintaining high-quality standards. Manufacturers are constantly seeking innovative ways to improve efficiency, such as implementing automation and robotics in their production processes. This helps to reduce labor costs, increase productivity, and ensure consistent product quality. Furthermore, the industry is also challenged by the need to adapt to changing market dynamics and customer demands. Manufacturers must be agile and responsive to market shifts, such as fluctuations in raw material prices or changes in consumer preferences. Innovations in this area include the use of advanced data analytics and market intelligence tools to anticipate and respond to market trends. To stay competitive, steel product manufacturers must embrace technological advancements and invest in research and development. Innovations in materials science, including the development of stronger and lighter alloys, can lead to improved product performance and expanded application possibilities. Overall, the steel product manufacturing industry is driven by the challenges of sustainability, cost-effectiveness, market dynamics, and technological advancements. Embracing innovation and finding solutions to these challenges will determine the success and growth of companies in this sector.

- Q: How is steel different from iron?

- Steel is different from iron in terms of its composition and properties. While iron is a pure element, steel is an alloy, meaning it is a combination of iron and other elements such as carbon. This alloying process gives steel improved strength, durability, and resistance to corrosion compared to iron. Additionally, steel can be manipulated to have different properties by varying the amounts of alloying elements.

- Q: How is steel tubing used in the manufacturing of automobile exhaust systems?

- Steel tubing is commonly used in the manufacturing of automobile exhaust systems due to its durability, heat resistance, and ability to withstand high temperatures. It is used to create the exhaust pipes, which transport the exhaust gases from the engine to the rear of the vehicle. Additionally, steel tubing is also utilized for the construction of various components within the exhaust system, such as mufflers and catalytic converters, to ensure proper functioning and longevity of the system.

- Q: How do steel products contribute to the transportation industry?

- Steel products contribute to the transportation industry in various ways. Firstly, steel is used in the manufacturing of vehicles, such as cars, trucks, trains, and ships, providing them with structural strength and durability. Steel's high strength-to-weight ratio makes it ideal for constructing lightweight yet resilient bodies, frames, and components, enhancing overall safety and performance. Additionally, steel is employed in the production of infrastructure elements like bridges, tunnels, and railway tracks, ensuring their sturdiness and longevity. Overall, steel products play a crucial role in enhancing the reliability, efficiency, and safety of transportation systems worldwide.

- Q: How are steel pipes used in oil and gas pipelines?

- Steel pipes are used in oil and gas pipelines due to their strength, durability, and resistance to harsh conditions. These pipes are used to transport crude oil, natural gas, and other petroleum products over long distances. They are able to withstand high pressure and temperature variations, ensuring the safe and efficient transportation of these resources. Additionally, steel pipes are often coated with protective layers to prevent corrosion and ensure the longevity of the pipeline system.

- Q: What are the different types of steel cladding and roofing available?

- There are several types of steel cladding and roofing available in the market, including corrugated steel sheets, standing seam steel panels, metal shingles, and steel tiles. Each type offers unique features and benefits, such as durability, weather resistance, and aesthetic appeal, allowing individuals to choose the most suitable option for their specific needs and preferences.

- Q: How does steel pipe welding work?

- Steel pipe welding works by joining two pieces of steel pipe together using a welding process. The process typically involves heating the ends of the pipes to a high temperature and then applying pressure to fuse them together. This is done by using an electric arc or a gas flame to melt the edges of the pipes, creating a molten pool of metal. A filler material is often added to the molten pool to strengthen the joint. As the molten metal cools and solidifies, it forms a durable and strong bond between the pipes, creating a continuous pipeline.

- Q: What are the different types of steel wire mesh products?

- There are several types of steel wire mesh products, including welded wire mesh, woven wire mesh, expanded metal mesh, and perforated metal mesh. Each type has its own unique characteristics and is used for various applications such as fencing, construction, filtration, and reinforcement.

- Q: How are steel products used in the agricultural sector?

- Steel products are widely used in the agricultural sector for various purposes. They are used in the construction of buildings, sheds, and barns, providing sturdy and durable structures to keep animals, machinery, and crops safe. Steel is also used in the manufacturing of agricultural equipment such as tractors, plows, and irrigation systems, as it offers strength and reliability. Additionally, steel is used in the fabrication of storage tanks, grain silos, and fences, helping to store and protect agricultural produce. Overall, steel products play a crucial role in enhancing the efficiency and productivity of the agricultural sector.

- Q: What are the applications of steel mesh in mining operations?

- Steel mesh is commonly used in mining operations for various applications. One of its main uses is for ground support and reinforcement in underground mines. The mesh is installed to prevent rock falls, provide stability to the surrounding rock mass, and ensure the safety of miners. Additionally, steel mesh is used to create safety barriers and partitions, control ventilation and airflow, and separate different areas within the mine. Overall, steel mesh plays a crucial role in enhancing safety and productivity in mining operations.

Send your message to us

Hot Rolled Steel Billet China Supplier/Made In China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords