Steel Billet Made in China/ China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications:

Type | Steel billet / Square steel/ Steel square bar |

Standard grade | 3SP/PS, 5SP/PS, Q195, Q235, Q255, Q275, 20MnSi etc. |

MOQ | 1000 MT |

Technique | Hot rolled, Continuous casting and rolling |

Size | 50*50mm ~ 160*160mm |

Length | 3~12m |

Packing | Loose packing, in bundle |

Payment terms | T/T, L/C at sight, Usance L/C |

Trade terms | EXW, FOB, CFR, CIF |

Trans terms | FIO, FILO, FLT |

Inspection | Third party inspection accepted |

Delivery time | 15-30 days, according to the quantity |

Applications | carbon structural steel, wire rod, rod, deformed bars, profile steel, machine parts, and steel moulds etc . |

Note | Customized service is available (for sizes,length and chemical components etc.). |

Steel Grade:

Steel Grade | C % | Mn % | Si % | S % | P % |

Q195 | 0.06-0.12 | 0.25-0.50 | 0.30 Max | 0.04 Max. | 0.04 Max. |

Q235 | 0.12-0.22 | 0.30-0.60 | 0.30 Max. | 0.04 Max. | 0.04 Max. |

Q255 | 0.18-0.28 | 0.40-0.70 | 0.30 Max. | 0.045 Max. | 0.050 Max. |

Q275 | 0.27-0.38 | 0.50-0.80 | 0.30 Max. | 0.045 Max. | 0.045 Max. |

3SP | 0.14-0.22 | 0.40-0.85 | 0.15-0.30 | 0.050 Max. | 0.040 Max. |

5SP | 0.28-0.37 | 0.50-1.00 | 0.15-0.30 | 0.050 Max. | 0.040 Max. |

20MnSi | 0.17-0.25 | 1.00-1.60 | 0.40-0.80 | 0.050 Max. | 0.050 Max. |

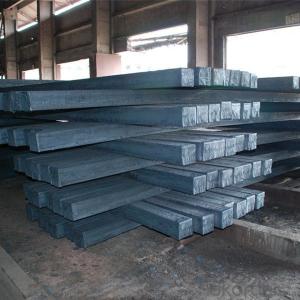

Products Picture:

FAQ

Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

Q: What's the MOQ?

A: Our MOQ is 25mt.

Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

Q: What is the payment terms?

A: T/T, L/C at sight

Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: How is steel rebar welded for reinforcement in concrete structures?

- Steel rebar is commonly welded for reinforcement in concrete structures using a technique called "lap splicing." This involves overlapping two rebar bars and then welding them together using electric arc welding or resistance welding methods. The welding process ensures a strong bond between the bars, providing enhanced strength and stability to the concrete structure.

- Q: How is steel wire used in the production of suspension systems for vehicles?

- Steel wire is used in the production of suspension systems for vehicles as it provides strength and durability. It is commonly used to create coil springs, which help support the weight of the vehicle and absorb shocks and vibrations. Steel wire is also used to create stabilizer bars, which improve the stability and handling of the vehicle by reducing body roll during turns. Overall, steel wire plays a crucial role in ensuring the smooth and safe operation of suspension systems in vehicles.

- Q: How is steel used in the construction of railway stations and terminals?

- Steel is used extensively in the construction of railway stations and terminals due to its strength, durability, and versatility. It is commonly used in the structural framework, roofing, and cladding of these buildings. Steel beams, columns, and trusses provide the necessary support and stability for large spans and heavy loads, ensuring the safety of the structure. Additionally, steel is used in the fabrication of platforms, stairs, handrails, and escalators, further enhancing the functionality and accessibility of railway stations and terminals.

- Q: How is steel used in the production of pipelines?

- Steel is commonly used in the production of pipelines due to its strength, durability, and corrosion resistance. It is used to manufacture the pipe itself, providing a reliable and long-lasting material for transporting fluids and gases over long distances. Steel pipes are also commonly coated or lined to further enhance their resistance to corrosion and improve their overall performance in various environments.

- Q: How is steel pipe coated for underground installations?

- Steel pipe is typically coated for underground installations through a process called external coating. This involves applying a layer of protective coating, such as fusion-bonded epoxy (FBE), to the exterior surface of the steel pipe. This coating acts as a barrier, preventing corrosion and ensuring longevity of the pipe in underground environments. Additionally, a layer of polyethylene tape or a shrink sleeve may be applied over the FBE coating for added protection against mechanical damage and moisture intrusion.

- Q: What are the common types of steel products used in the wastewater treatment industry?

- Some common types of steel products used in the wastewater treatment industry include stainless steel pipes, tanks, and fittings. These materials are resistant to corrosion and provide durability, making them suitable for handling and transporting wastewater. Additionally, steel gratings and screens are often used for filtration purposes in wastewater treatment plants.

- Q: How is steel pipe coated for corrosion protection?

- Steel pipe can be coated for corrosion protection through various methods, including hot-dip galvanizing, epoxy coating, and polyethylene wrapping. These processes provide a barrier between the steel pipe and the surrounding environment, preventing the pipe from coming into direct contact with moisture, chemicals, or other corrosive elements that could lead to its deterioration.

- Q: What is the role of steel in the manufacturing of appliances?

- Steel plays a crucial role in the manufacturing of appliances as it provides strength, durability, and heat resistance. It is commonly used as the primary material for appliance bodies, frames, and internal components due to its ability to withstand high temperatures and withstand daily wear and tear. Additionally, steel's malleability allows for complex shapes and designs, making it versatile for various appliance types.

- Q: What are the different types of steel angles and their applications in construction?

- There are several types of steel angles used in construction, including equal angles, unequal angles, and L-shaped angles. Equal angles have sides of equal length and are typically used for structural support, such as in framing or bracing. Unequal angles have sides of different lengths and are commonly used for edge protection, as well as in applications where a non-standard angle is required. L-shaped angles, also known as corner or angle irons, are used for reinforcing corners and edges in construction projects. Overall, steel angles are versatile and widely used in various construction applications due to their strength and structural stability.

- Q: What are the different types of steel flooring and decking available?

- There are several types of steel flooring and decking available, including open mesh grating, diamond pattern grating, plank grating, and perforated metal decking. Each type has its own unique design and characteristics, offering various levels of strength, durability, and slip resistance for different applications.

Send your message to us

Steel Billet Made in China/ China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords