Steel Billets for Rebar Rolling Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Steel BilletsWe are one of steel manufacturer, our company specializes in manufacturing profile steel products such as H beams,I beams , Channel steel,and also can find some best quality angle steel,steel plate,steel pipe ,steel coils and many kinds of steel products of this kind.

Company Main Product Introduction:

Steel billet

Steel Profile:H-Beam/I-Beam/Equal Angle/Unequal Angle/U Channel /Flat Bar

Steel Plate:Hot Rolled Coil/Hot Rolled Checkered Coil/Cold Rolled Coil/Cutting Sheet

Wire Bar: Round Bar /Wire Rod/Deformed Bar

Steel Pipes: Seamless Pipe, Square/Round Pipes

Galvanized Steel: Angle/Channel/I-Beam/Round Bar/Flat Bar/Round-Square Pipe

Application:

Wire rod, deformed bars, rebar, profile steel, mechine parts and so on.

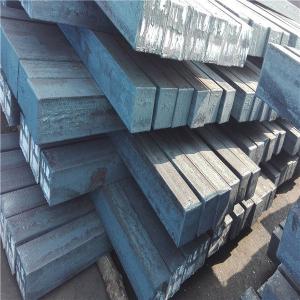

Proct Picture:

Specification:

| Type | Square, rectangular |

| Standard | GB, ASTM |

| Size | 60X60-150X150mm |

| Length | 6-12M or customised |

| Processing | Hot rolled continuous cast |

| Packing | Export standard packing |

Adventage:

1. Prime quality and competitive pirce

2. Good reputation and large market

3. Big company scale

4. Good service and prompt reply

Reasons for choosing us:

1. We have a large substantiality as our backup force. Our mill covers an area of 40000 square meters, has a modern standard workshop more than 19800 square meters. The existing staff of more than 180 people. The registered capital of twenty million yuan.

2. We have many qualified raw material supplier.

3. The company has perfect management mode and advanced processing technology.

4. We have the country's leading production equipment and strong production capacity.

5. Our company has a strong aftersales service platform, and our leaders are glad to make guidance personally for every feedback from customers.

6. Our company has a strong reputation system: SGS, ISO Certification, etc.

- Q: How are steel gratings used in the construction of walkways and platforms?

- Steel gratings are used in the construction of walkways and platforms to provide a strong and durable surface for people to walk on. They are designed with an open grid pattern, allowing for easy passage of air, light, and water, while providing sufficient grip and stability. These gratings are installed on the framework of the walkway or platform, creating a safe and secure footing for pedestrians, even in wet or slippery conditions. Additionally, steel gratings are resistant to corrosion and can withstand heavy loads, making them ideal for high-traffic areas in construction projects.

- Q: How are steel products used in the construction of theme-based science discovery centers?

- Steel products are commonly used in the construction of theme-based science discovery centers to provide structural support and stability. Steel beams and columns are used to create the framework of the building, ensuring it can withstand the weight of the structure and any potential loads. Additionally, steel is used for roofing, walls, and flooring, offering durability and resistance to fire and other hazards. Steel is also used to create intricate architectural designs and shapes, allowing for flexibility and creativity in the construction process. Overall, steel products play a vital role in ensuring the safety, functionality, and aesthetic appeal of theme-based science discovery centers.

- Q: How is steel sheet formed and shaped?

- Steel sheet is formed and shaped through a process called steel sheet metal forming, which involves different methods such as rolling, bending, and stamping. Initially, steel is melted and cast into large slabs, which are then hot rolled to reduce the thickness and achieve the desired dimensions. This hot rolled sheet is then cold rolled to further refine the surface finish and improve dimensional accuracy. To shape the steel sheet, various techniques like bending, where the sheet is bent into a desired angle or curve, and stamping, where a die is used to cut and shape the sheet, are employed. These processes allow for the creation of steel sheets in a wide range of sizes and shapes to meet specific manufacturing needs.

- Q: What are the applications of steel wire mesh in marine environments?

- Steel wire mesh has various applications in marine environments. One common use is for the construction of marine structures such as seawalls, breakwaters, and jetties. The wire mesh is used to reinforce concrete and provide added strength to withstand the harsh conditions of the ocean. Additionally, steel wire mesh is used for the fabrication of marine cages for aquaculture, as it provides a strong and durable enclosure for fish and other marine organisms. The mesh is also used in marine filtration systems, preventing debris and marine life from entering and clogging pipes and equipment. Overall, steel wire mesh is essential in marine environments due to its strength, durability, and corrosion resistance properties.

- Q: What are the different types of steel bars and rods available?

- There are several different types of steel bars and rods available, including mild steel bars, carbon steel bars, alloy steel bars, stainless steel bars, and tool steel bars. Each type varies in terms of its composition, strength, and intended use.

- Q: What are the different types of steel scaffolding systems?

- There are several types of steel scaffolding systems, including frame scaffolding, tube and clamp scaffolding, system scaffolding, and suspended scaffolding. Frame scaffolding consists of vertical frames connected by horizontal and diagonal braces, providing a stable structure. Tube and clamp scaffolding uses steel tubes and clamps to create a flexible and adjustable system. System scaffolding utilizes prefabricated components, such as modular frames and braces, for quick assembly and versatility. Suspended scaffolding is suspended from the roof or other elevated structure, allowing workers to access hard-to-reach areas.

- Q: What are the different types of steel fencing and their applications?

- There are several different types of steel fencing, each with their own unique applications. Some common types include chain link fencing, ornamental steel fencing, and mesh panel fencing. Chain link fencing is often used for residential or commercial purposes due to its affordability and durability. Ornamental steel fencing is more decorative and is commonly used for residential properties or as a stylish addition to parks and gardens. Mesh panel fencing is versatile and can be used for various applications, such as securing construction sites or creating animal enclosures. Ultimately, the choice of steel fencing depends on the specific needs and requirements of the project or property.

- Q: How is steel used in the manufacturing of textile materials?

- Steel is not typically used in the manufacturing of textile materials. Instead, textiles are usually made from natural fibers like cotton or synthetic fibers like polyester. Steel, on the other hand, is commonly used in the construction of textile machinery or equipment, such as looms or knitting needles.

- Q: How is steel used in the manufacturing of storage tanks?

- Steel is commonly used in the manufacturing of storage tanks due to its durability, strength, and resistance to corrosion. It provides a sturdy structure that can withstand high pressures and extreme weather conditions. Steel tanks can be fabricated in various sizes and shapes to accommodate different storage needs, making them versatile for storing various substances such as water, oil, chemicals, and gases.

- Q: What are the different types of steel angles and channels available?

- There are several different types of steel angles and channels available, including equal angles, unequal angles, c-channels, and u-channels. Equal angles have both sides of equal length and are commonly used for structural applications. Unequal angles have one side longer than the other and are often used for bracing or support. C-channels have a shape resembling the letter "C" and are frequently used for structural framing or as purlins in metal buildings. U-channels have a shape resembling the letter "U" and are commonly used for edging, trim, or as track for sliding doors.

Send your message to us

Steel Billets for Rebar Rolling Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords