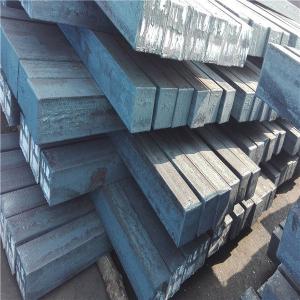

Steel Billets for Rebar Rolling From Mill China (130*130*12000mm)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

GB Q195-235,SS400,3SP,4SP,5SP steel billets1.standard: GB,JIS,ASTM,DIN,BS,EN.

2.process: hot rolled or continuous casting.

3.size: 100*100-150*150mm

4.MOQ: 1000mt

5.FOB unit price: 230-250usd/mt

6. third-party inspection: allowed.

7.chemical composition:

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Product picture

FAQ

Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

Q: What's the MOQ?

A: Our MOQ is 25mt.

Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

Q: What is the payment terms?

A: T/T, L/C at sight

Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: How is steel tubing used in the manufacturing of automobile exhaust systems?

- Steel tubing is commonly used in the manufacturing of automobile exhaust systems due to its durability, heat resistance, and ability to withstand high temperatures. It is used to create the exhaust pipes, which transport the exhaust gases from the engine to the rear of the vehicle. Additionally, steel tubing is also utilized for the construction of various components within the exhaust system, such as mufflers and catalytic converters, to ensure proper functioning and longevity of the system.

- Q: What are the different types of steel sections used in bridges?

- There are several different types of steel sections used in bridges, including I-beams, H-beams, box girders, trusses, and arches. Each of these sections offers unique structural properties and can be used in various bridge designs depending on the specific requirements and loads that need to be supported.

- Q: What are the properties of weathering steel for outdoor sculptures?

- Weathering steel, also known as Corten steel, is widely used for outdoor sculptures due to its unique properties. It is highly resistant to corrosion, making it ideal for withstanding outdoor elements without the need for additional protective coatings. Weathering steel forms a protective rust-like layer on its surface, which not only enhances its aesthetic appeal but also acts as a barrier against further corrosion. This self-protecting quality makes it a durable and low-maintenance material for outdoor sculptures. Additionally, weathering steel has a high tensile strength, allowing for the creation of intricate and large-scale sculptures.

- Q: How is steel used in the production of medical devices and equipment?

- Steel is commonly used in the production of medical devices and equipment due to its strength, durability, and resistance to corrosion. It is used to manufacture surgical instruments, orthopedic implants, hospital beds, and various other medical tools. Additionally, stainless steel, a type of steel containing chromium, is often used to ensure sterilization and prevent infections in healthcare settings.

- Q: What are the different types of steel springs and their uses?

- There are several types of steel springs, each designed for specific applications. Some common types include compression springs, which are used to resist compressive forces and store energy; extension springs, which resist stretching and are commonly found in trampolines or garage doors; torsion springs, which generate rotational force and are used in clothespins or mousetraps; and flat springs, which provide flexibility in limited spaces, such as in automotive suspensions. Each type of spring has a unique design and purpose, allowing them to be utilized in a wide range of industries and products.

- Q: What are the different types of steel springs and their applications?

- There are several different types of steel springs, each with its own unique characteristics and applications. Some common types include compression springs, which are used in a wide range of applications such as automotive suspension systems, mattresses, and industrial machinery. Tension springs, also known as extension springs, are commonly found in garage doors, trampolines, and various mechanical devices. Torsion springs, on the other hand, are used in many applications that require rotational force, such as in clothespins and door hinges. Additionally, there are specialized springs like wave springs, which are often used in electronics and medical devices due to their compact size and high reliability. Overall, the choice of steel spring type depends on the specific requirements of the application, including load capacity, flexibility, and space constraints.

- Q: How is steel pipe coated for corrosion protection?

- Steel pipe can be coated for corrosion protection through various methods, including hot-dip galvanizing, epoxy coating, and polyethylene wrapping. These processes provide a barrier between the steel pipe and the surrounding environment, preventing the pipe from coming into direct contact with moisture, chemicals, or other corrosive elements that could lead to its deterioration.

- Q: How is steel used in the construction of sports facilities?

- Steel is used in the construction of sports facilities for various purposes, such as the framework for stadiums, arenas, and indoor sports complexes. It provides structural support, allowing for large open spaces and the ability to accommodate thousands of spectators. Steel is also used in the construction of roofs and canopies, providing durability and resistance to harsh weather conditions. Additionally, steel is utilized in the fabrication of seating, stairs, and other architectural elements, ensuring safety and functionality in sports facilities.

- Q: What are the common uses of steel in the telecommunications industry?

- Steel is commonly used in the telecommunications industry for the construction of towers, transmission lines, and other infrastructure. It provides the necessary strength, durability, and stability needed to support and transmit signals over long distances. Additionally, steel is used in the manufacturing of various telecommunications equipment, such as antennas, satellite dishes, and cable trays.

- Q: What are the applications of steel in the water treatment industry?

- Steel is commonly used in the water treatment industry for various applications. It is used in the construction of water treatment plants, pipelines, and storage tanks due to its durability and resistance to corrosion. Steel is also used in the manufacturing of screens, filters, and grates, as well as in the fabrication of equipment such as pumps and valves. Additionally, steel is utilized in the production of chemical storage and dosing systems, ensuring the safe and efficient treatment of water.

Send your message to us

Steel Billets for Rebar Rolling From Mill China (130*130*12000mm)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords