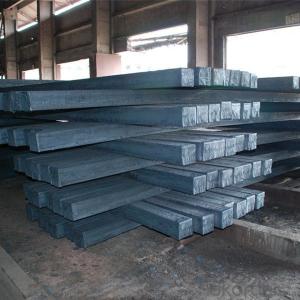

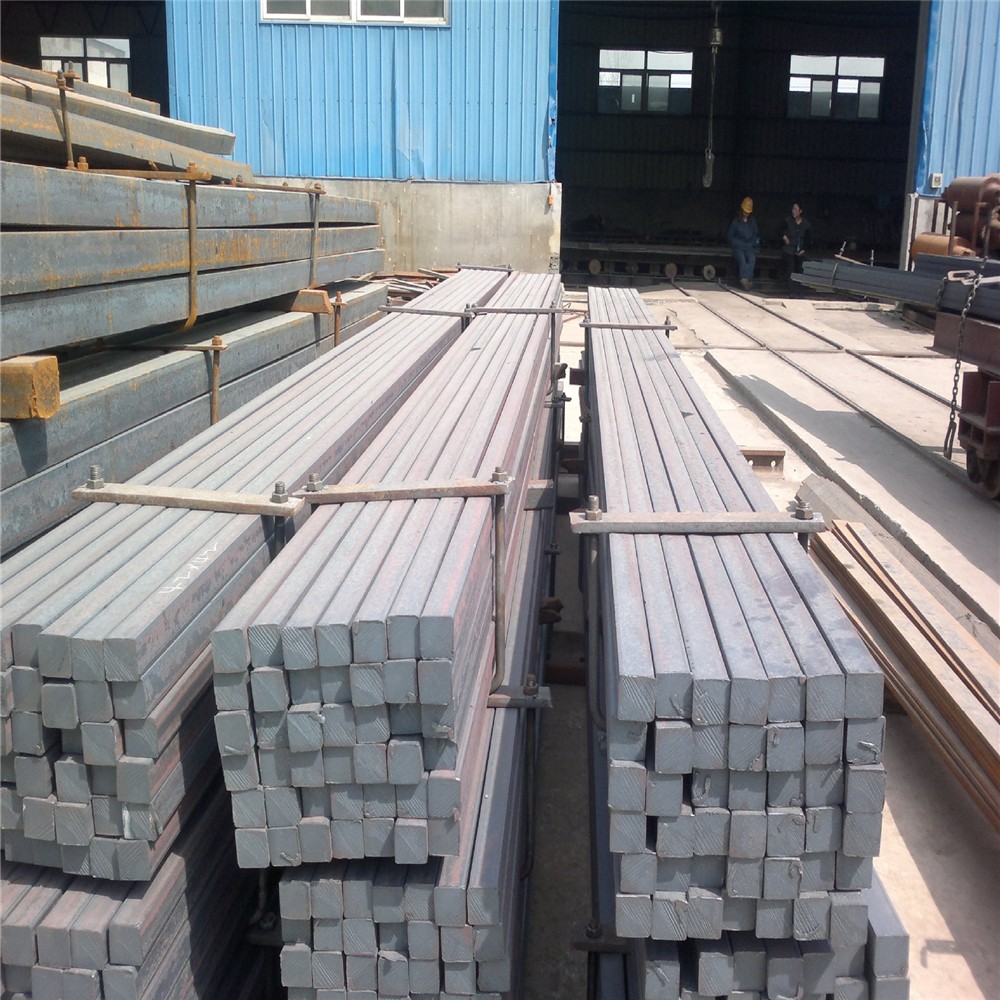

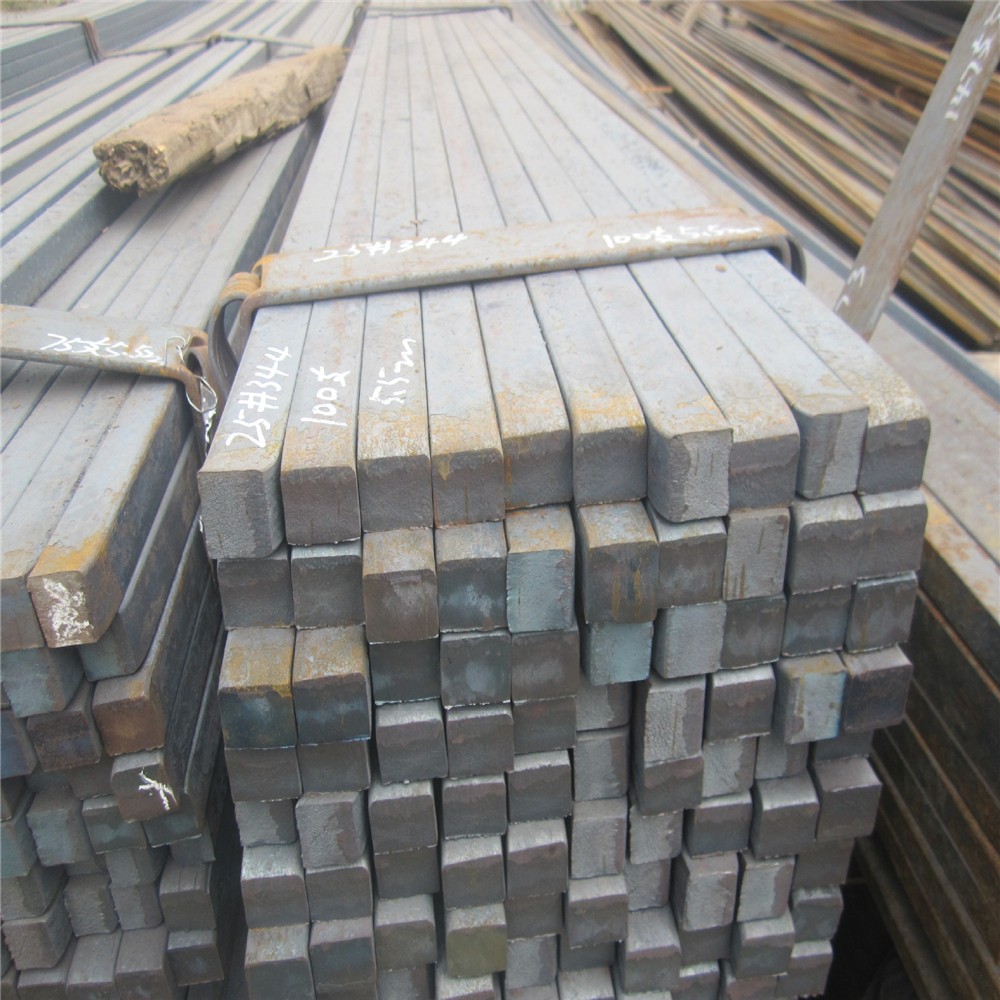

Square Steel Billets for Rolling Rebar From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

| Product Name | Steel Billets |

| Size | 60×60mm, 100×100mm, 120×120mm, 130×130mm, 150×150mm |

| Length | 6M, 9M, 12M |

| Grade | Q195, Q235, Q275, 3SP, 5SP, 20MnSi, Etc |

| Standard | ASTM, GB, JIS |

| Chemical Composition | Q235: C: 0.14-0.22% MN:0.3-0.7% SI: 0.3% max P:0.045%max S:0.045%max Q275 C: 0.27-0.38% MN:0.5-0.8% SI: 0.3% max P:0.045%max S:0.045%max |

| Delivery | 30-45days after L/C |

Pre-sale Service

1. Sample can be offered with sample charge and courier fee by buyer's side.

2. We have full stock,and can deliver within short time.Many styles for your choices.

3. OEM and ODM order are accepted, Any kind of logo printing or design are available.

4. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you

5. All of our products are produce by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service.

6. We have 8 year experience of design, manufacture and sell lingerie, we cherish every order from our honor.

After you choose

1. We will count cheapest shipping cost and make invoice to you at once.

2. Check quality again, then send out to you at 1-2 working day after your payment,

3. Email you the tracking no, and help to chase the parcels until it arrive you.

After-sale choose

1. We are very glad that customer give us some suggestion for price and products.

2. If any question,please contact with us freely by E-mail or Telephone.

- Q: What are the different types of steel sheets and their uses in the packaging industry?

- There are several types of steel sheets used in the packaging industry, including tinplate, galvanized steel, and stainless steel. Tinplate is a thin steel sheet coated with a layer of tin, making it highly resistant to corrosion. It is commonly used for making food cans and beverage containers due to its ability to preserve the contents' freshness. Galvanized steel sheets are coated with a layer of zinc, which provides excellent rust resistance. They are often utilized for packaging materials that require durability and strength, such as metal drums and pails. Stainless steel sheets, known for their corrosion resistance and hygienic properties, are used in the packaging industry for applications like pharmaceutical packaging, cosmetic containers, and high-end food packaging.

- Q: What are the uses of steel grating in safety platforms?

- Steel grating is commonly used in safety platforms for various purposes. Firstly, it provides a sturdy and durable surface that can withstand heavy loads, ensuring the safety of workers or individuals standing or walking on the platform. Additionally, the open design of steel grating allows for efficient drainage of liquids, preventing the accumulation of water or other substances that could cause slipping hazards. Moreover, the anti-slip properties of steel grating enhance traction and reduce the risk of accidents. Overall, steel grating is essential in safety platforms as it offers strength, drainage capabilities, and slip resistance, ensuring a secure and safe environment.

- Q: What are the different types of steel gratings and walkways available?

- There are several different types of steel gratings and walkways available, including standard welded steel gratings, pressure-locked gratings, riveted gratings, and heavy-duty gratings. These gratings come in various designs and sizes to cater to different applications and load requirements. Additionally, there are also different surface finishes available, such as galvanized, painted, or untreated, depending on the desired level of corrosion resistance and aesthetic appeal.

- Q: What are the different methods of joining steel components together?

- There are several methods of joining steel components together. Some common methods include welding, bolting, riveting, adhesive bonding, and soldering. Welding involves melting and fusing the steel components together using heat, while bolting involves using bolts and nuts to secure the components. Riveting involves using rivets to join the components by deforming and clinching them. Adhesive bonding uses specialized adhesives to bond the components together, while soldering involves melting a filler metal to join the components. Each method has its advantages and limitations, depending on factors such as the application, strength requirements, and ease of disassembly.

- Q: How is steel pipe coated for corrosion protection?

- Steel pipe can be coated for corrosion protection using various methods, including applying a layer of zinc through hot-dip galvanizing, using epoxy or polyethylene coatings, or employing a combination of both. These coatings create a barrier between the steel and the surrounding environment, preventing corrosion and extending the lifespan of the pipe.

- Q: What are the advantages of using steel products in the automotive industry?

- There are several advantages of using steel products in the automotive industry. Firstly, steel is known for its high strength and durability, making it an ideal material for constructing vehicle bodies and frames. This ensures enhanced safety and protection for passengers in case of accidents or collisions. Secondly, steel has excellent formability, allowing manufacturers to create complex shapes and designs for various automotive components. This flexibility in design helps to optimize the overall performance and efficiency of vehicles. Moreover, steel is readily available and cost-effective compared to alternative materials. This allows automakers to produce vehicles at a more affordable price point, making them accessible to a wider range of consumers. Additionally, steel has good corrosion resistance, which is crucial for automotive applications as vehicles are exposed to harsh environments and weather conditions. This helps to extend the lifespan of vehicles and reduces maintenance costs. Lastly, steel is a highly sustainable material as it is recyclable. This aligns with the automotive industry's increasing focus on sustainability and environmental responsibility. Overall, the advantages of using steel products in the automotive industry include strength, durability, formability, cost-effectiveness, corrosion resistance, and sustainability.

- Q: How is steel tubing used in the oil and gas industry?

- Steel tubing is used in the oil and gas industry for a variety of purposes such as drilling, production, and transportation. It is used as casing and tubing in oil wells to provide structural support and prevent the collapse of the wellbore. Steel tubing is also used for transporting oil and gas from the well to the surface, as well as for various equipment and infrastructure in oil and gas processing facilities.

- Q: How is steel used in the production of bicycles and motorcycles?

- Steel is commonly used in the production of bicycles and motorcycles due to its durability and strength. It is used in various parts such as the frame, handlebars, and forks, providing structural integrity and stability. Steel's high tensile strength allows for lightweight yet sturdy designs, enabling better handling and performance. Additionally, steel's versatility allows for customization and shaping into different components, making it an ideal material for constructing these vehicles.

- Q: What are the different types of steel flooring and decking available?

- There are several types of steel flooring and decking available, including steel grating, steel checker plate, and steel floor decking. Steel grating consists of interlocking bars or grids that provide a strong and durable flooring solution. Steel checker plate features raised patterns or diamond-shaped projections that enhance slip resistance and aesthetic appeal. Steel floor decking is a popular choice for construction projects, as it provides a sturdy and cost-effective solution for creating elevated floors and mezzanines.

- Q: Can steel be used in the production of food-grade equipment?

- Yes, steel can be used in the production of food-grade equipment. Stainless steel, in particular, is commonly used in the food industry due to its corrosion resistance, durability, and easy-to-clean properties. It is non-reactive, does not impart any flavors or odors to the food, and meets the necessary hygiene and safety standards.

Send your message to us

Square Steel Billets for Rolling Rebar From China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords