Steel Billet Made in China/ China Manufacture/GB ASTM DIN

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

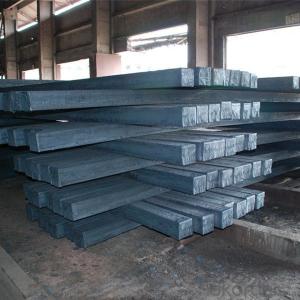

Square steel billet

1.Chemical Analysis | |||

Grade | Carbon(%) | Manganese(%) | Silicon(%) |

A | 0.14~0.22 | 0.30~0.65 | Max0.30 |

B | 0.12~0.20 | 0.37~0.67 | Max0.30 |

C | Max0.18 | 0.35~0.80 | Max0.30 |

D | Max0.17 | 0.35~0.80 | Max0.35 |

2.Mechnical Properties | |||

Tensile Strength(σb/Mpa) | Elongation(δ5/%) | ||

375---500 | ≥26(a≤16mm) | ||

3.basic information | |||

length | Spectfication(mm) | Material quality | Executive standard |

6m | 120*120 | Q235 | GB700-88 |

4.Trade information | |||

Price terms | Payment terms | Delivery time | Packing |

FOB/ CIF | T/T, L/C | Within 30 days | bundles |

Product Picture

FAQ

Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

Q: What's the MOQ?

A: Our MOQ is 1000mt.

Q: What's the delivery time?

A: It will take about 40 days after TT or L/C.

Q: What is the payment terms?

A: T/T, L/C at sight

Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: What are the different types of steel roofing materials?

- There are several types of steel roofing materials available, including corrugated steel, standing seam steel, and steel shingles. Each type offers its own unique benefits and aesthetic appeal.

- Q: What are the different types of steel rods and their applications?

- There are several types of steel rods commonly used in construction and manufacturing. Some common types include mild steel rods, stainless steel rods, carbon steel rods, and alloy steel rods. Mild steel rods are widely used due to their affordability and versatility. They are commonly used in general construction, reinforcement of concrete structures, and fabrication of fences and gates. Stainless steel rods offer excellent corrosion resistance and are used in applications where hygiene and aesthetic appeal are important, such as in food processing, pharmaceuticals, and marine environments. Carbon steel rods are known for their high strength and durability. They are commonly used in heavy-duty construction projects, such as bridges, high-rise buildings, and infrastructure. Alloy steel rods are made from a combination of different metals, offering specific properties such as increased strength, hardness, and resistance to wear and tear. They are often used in applications that require high performance, such as automotive parts, machinery, and tooling. Overall, the choice of steel rod depends on the specific requirements of the application, considering factors such as strength, corrosion resistance, cost, and environmental conditions.

- Q: What are the common uses of steel in the defense industry?

- Steel is commonly used in the defense industry for a variety of applications such as manufacturing armored vehicles, naval ships, aircraft carriers, submarines, and tanks. It is also utilized for constructing military infrastructure, including bunkers, fortifications, and military base facilities. Furthermore, steel is essential for producing weapons, ammunition, and equipment for the armed forces. Its high strength, durability, and resistance to impact make it an ideal material for ensuring the safety and effectiveness of defense operations.

- Q: Can steel be recycled?

- Yes, steel can be recycled.

- Q: How is steel used in the production of marine vessels?

- Steel is used in the production of marine vessels due to its high strength, durability, and resistance to corrosion. It is used to construct the hull and other structural components of the vessel, providing stability and ensuring the vessel's longevity in harsh marine environments.

- Q: How does the quality of steel affect its performance?

- The quality of steel directly affects its performance as it determines its strength, durability, and resistance to various factors such as corrosion, impact, and fatigue. Higher-quality steel, often achieved through precise manufacturing processes and alloying techniques, exhibits superior mechanical properties and is capable of withstanding higher loads and stresses. It also offers better resistance to wear, deformation, and fracturing, making it suitable for demanding applications in industries like construction, automotive, and aerospace. In contrast, lower-quality steel may exhibit reduced strength and toughness, leading to decreased performance and potential structural failures. Therefore, the quality of steel plays a crucial role in determining its overall performance and suitability for specific applications.

- Q: What are the advantages of using steel for construction purposes?

- There are several advantages of using steel for construction purposes. Firstly, steel is incredibly strong and durable, making it ideal for constructing buildings and structures that need to withstand heavy loads and harsh weather conditions. Secondly, steel is a highly versatile material that can be easily shaped and molded into various forms, allowing for creative and innovative designs in construction. Additionally, steel is fire-resistant, which enhances the safety of buildings and reduces the risk of damage and collapse in the event of a fire. Moreover, steel is a sustainable and environmentally-friendly choice, as it can be recycled and reused, minimizing waste and reducing the carbon footprint of construction projects. Overall, the use of steel in construction offers numerous benefits in terms of strength, versatility, safety, and sustainability.

- Q: What is the role of steel in the telecommunications industry?

- Steel plays a crucial role in the telecommunications industry as it is used to construct telecommunication towers and infrastructure. These structures provide the necessary support for antennas, cables, and other equipment required for transmitting and receiving signals. The strength and durability of steel make it an ideal material for withstanding harsh weather conditions and ensuring the stability and reliability of telecommunications networks.

- Q: How does steel tube bending work?

- Steel tube bending works by applying force to a straight steel tube to deform it into a desired curved shape. This force is typically exerted through a combination of heat and mechanical pressure, which softens the steel and allows it to be bent without breaking. Different methods, such as mandrel bending or induction bending, are used depending on the size and thickness of the tube.

- Q: How is steel used in the construction of industrial buildings?

- Steel is commonly used in the construction of industrial buildings due to its strength and durability. It is often used for structural support, such as beams, columns, and frames, providing stability and withstanding heavy loads. Additionally, steel is used for cladding, roofing, and siding, offering protection against weather elements. Its versatility allows for easy customization and modification, making it a preferred choice in industrial construction.

Send your message to us

Steel Billet Made in China/ China Manufacture/GB ASTM DIN

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords