Square Steel Billets Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Square Steel Billets Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Specification

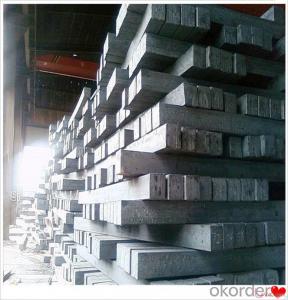

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

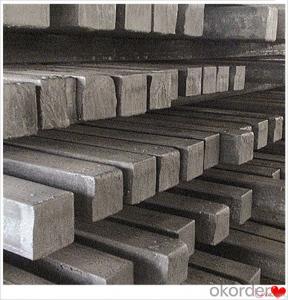

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

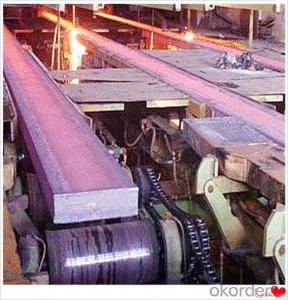

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

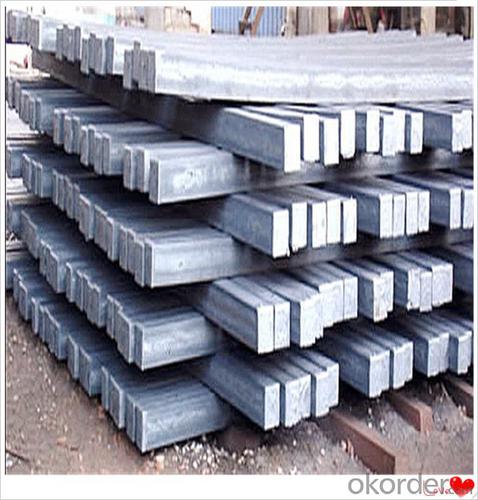

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: What are the safety precautions to be followed while handling steel billets?

- When handling steel billets, it is important to follow certain safety precautions to prevent accidents and injuries. Some of the key safety measures to be followed include: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as gloves, safety glasses, and steel-toed boots, to protect yourself from potential hazards like sharp edges or falling objects. 2. Lifting Techniques: Use proper lifting techniques and equipment, such as cranes or forklifts, to handle steel billets. Avoid attempting to lift them manually, as they can be heavy and may cause strain or back injuries. 3. Secure Storage and Transportation: Ensure that steel billets are securely stored and transported to prevent them from rolling or falling. Use appropriate containers or racks to keep them stable and avoid any mishaps. 4. Avoid Overloading: Do not overload lifting equipment or storage containers beyond their recommended weight limits. Exceeding these limits can compromise their stability and lead to accidents. 5. Clear Work Area: Maintain a clean and organized work area, free from clutter or debris, to prevent slips, trips, and falls while handling steel billets. 6. Proper Training: Ensure that all personnel involved in handling steel billets receive proper training on safe handling practices, equipment usage, and emergency procedures. 7. Communication and Signage: Clearly communicate and display warning signs or labels indicating the presence of steel billets in the vicinity, helping to prevent accidental contact or collisions. By following these safety precautions, you can minimize the risks associated with handling steel billets and maintain a safe working environment.

- Q: What are the different types of steel billet packaging materials?

- Some of the different types of steel billet packaging materials include wooden crates, steel drums, plastic wrapping, and cardboard boxes.

- Q: What are the different surface treatment options for steel billets?

- Some of the different surface treatment options for steel billets include pickling, shot blasting, galvanizing, painting, and powder coating.

- Q: What is the role of steel billets in the manufacturing of pressure vessels?

- The manufacturing of pressure vessels heavily relies on steel billets, which have a crucial role to play. Pressure vessels, designed to contain fluids or gases at higher pressures than atmospheric pressure, find applications across industries like oil and gas, chemical, pharmaceutical, and more. Steel billets serve as the raw material for constructing pressure vessels, forming a significant part of the manufacturing process. These semi-finished products are obtained through continuous casting or hot rolling of steel ingots and have a rectangular or square cross-section. Typically, they are made from carbon steel or alloy steel. Steel billets possess key properties that make them ideal for pressure vessel manufacturing. Their excellent strength and toughness allow them to withstand the high internal pressure exerted by fluids or gases, ensuring the integrity and safety of the vessel. Another important property of steel billets is their good weldability. This is crucial for fabricating pressure vessels as welding is a common joining technique. The weld joints must have comparable strength to the base material, and steel billets allow for strong and reliable welds during the fabrication process. In addition, steel billets can be easily formed and shaped into the desired size and dimensions for pressure vessels. They can be forged, rolled, or extruded to create various components like cylindrical bodies, heads, nozzles, and flanges. This versatility allows for customization based on specific pressure vessel requirements. Moreover, steel billets are known for their corrosion resistance, which is vital for pressure vessels in contact with corrosive fluids or gases. The selection of the appropriate steel grade for the billets ensures the vessel can withstand the corrosive environment and maintain its integrity over time. In conclusion, steel billets are indispensable in pressure vessel manufacturing as they provide the necessary raw material with properties required to withstand high-pressure conditions. Their strength, weldability, formability, and corrosion resistance make them an excellent choice for constructing reliable and durable pressure vessels used across various industries.

- Q: How are steel billets used in the production of railway tracks?

- Steel billets are the raw materials used in the production of railway tracks. They are heated, shaped, and rolled to form long, flat bars known as rails. These rails are then laid on the trackbed, forming the foundation for the tracks on which trains run.

- Q: Fish pole carbon cloth tcf. Vcf. Svf. Hcf. On behalf of what?

- Carbon cloth classification, a semicolon after the term, usually called HVF and SVF, where SVF is divided into VCF and so on! The index of carbon fiber is T (ton), common carbon part is 20T-30T commonly. HVF is 30T-40T, SVF is 40T-60T. SVF lighter than HVF, higher strength, better elasticity of the material of products: Di 46T SVF meaning 60T ultra high strength and high modulus carbon fiber cloth, HVF carbon fiber reinforced 30T 40T strength and high modulus. But the domestic ordinary carbon fishing rod material is generally 24T carbon fiber cloth. The higher the T value, the higher the strength and elasticity of the material.

- Q: How do steel billets contribute to the manufacturing of furniture and fixtures?

- Due to their unique properties, steel billets are indispensable in the production of furniture and fixtures. The strength and stability they offer are essential for constructing these items, providing a solid framework that can support their weight and load-bearing capacity. This ensures that the furniture and fixtures will remain functional for an extended period of time. Additionally, the malleability of steel billets allows for the creation of intricate designs and shapes, enhancing the aesthetic appeal of furniture and fixtures. Manufacturers can take advantage of this flexibility to produce a wide range of styles and patterns that cater to different consumer preferences and interior design themes. Moreover, steel billets can be easily welded, making them perfect for joining various components together during the manufacturing process. This welding capability ensures a seamless and secure construction, ultimately improving the overall quality and durability of the furniture and fixtures. Furthermore, steel billets possess corrosion-resistant properties, making them suitable for indoor and outdoor furniture and fixtures alike. This resistance to rust and decay guarantees that these items can withstand harsh environmental conditions, preserving their appearance and structural integrity over time. In conclusion, the role of steel billets in the manufacturing of furniture and fixtures cannot be overstated. Their strength, malleability, weldability, and corrosion resistance contribute to the durability, design flexibility, and longevity of these items, making them a preferred choice for both manufacturers and consumers.

- Q: What are the common quality control measures for steel billets?

- Some common quality control measures for steel billets include visual inspection for surface defects, dimensional checks to ensure the correct size and shape, hardness testing to verify the desired hardness level, chemical analysis to determine the composition of the steel, and non-destructive testing techniques such as ultrasonic or magnetic particle inspection to detect internal flaws or cracks. Additionally, mechanical property testing, such as tensile or impact testing, may be performed to evaluate the strength and toughness of the billets.

- Q: What is a steel billet?

- A steel billet is a semi-finished product in the form of a rectangular or square shape made from molten steel that has been solidified and cooled. It serves as a raw material for various steel products and is further processed through rolling or forging to be transformed into bars, rods, or other desired shapes.

- Q: What are the challenges faced in the distribution and supply chain of steel billets?

- The distribution and supply chain of steel billets encounter several challenges. Firstly, transportation poses a major obstacle due to the heavy and bulky nature of steel billets. Specialized equipment and infrastructure are necessary, which can result in higher logistics costs and difficulties in finding suitable transport options, particularly for international shipments. Secondly, the storage and inventory management of steel billets present challenges. Proper storage facilities are required to prevent corrosion and damage. Moreover, managing inventory levels and ensuring timely deliveries become complex as steel billets are sourced from multiple suppliers and delivered to various locations. Thirdly, maintaining quality control is a significant challenge. Consistent quality throughout the supply chain demands strict adherence to quality standards and effective quality control measures. Regular inspections, testing, and certification processes are necessary to ensure the integrity and suitability of the steel billets. Another challenge stems from fluctuating demand and market conditions. The steel industry is highly cyclical, with demand and prices influenced by economic fluctuations and global market trends. Consequently, forecasting demand, managing production capacity, and optimizing inventory levels to meet customer requirements while minimizing costs become difficult. Furthermore, global trade regulations and customs procedures create challenges. Compliance with various import and export regulations, including trade restrictions and tariffs, can affect the flow of steel billets across different countries, leading to delays and additional costs. Lastly, ensuring sustainable and responsible sourcing practices is increasingly important. Meeting environmental and social standards, such as responsible sourcing of raw materials and reducing carbon emissions, poses challenges for steel billet manufacturers and distributors. Implementing sustainable practices throughout the supply chain may involve additional costs and complexities. In conclusion, the distribution and supply chain of steel billets face challenges related to transportation, storage, quality control, demand fluctuations, trade regulations, and sustainable sourcing. Overcoming these challenges necessitates effective planning, strong partnerships, and the implementation of efficient processes to ensure a smooth and reliable supply of steel billets to customers.

Send your message to us

Square Steel Billets Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords