Steel Billet for Rebar Steel Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Billet for Rebar Steel Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

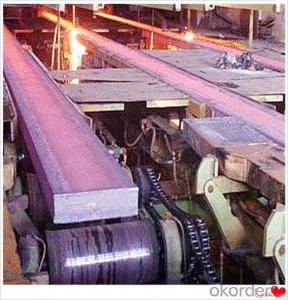

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

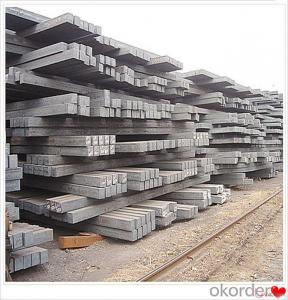

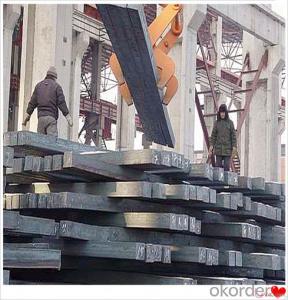

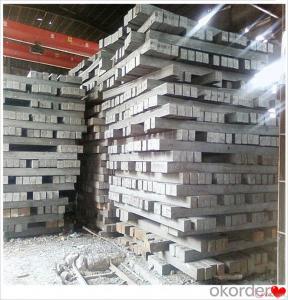

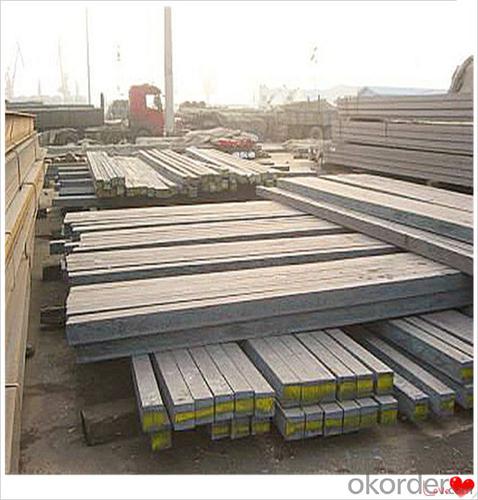

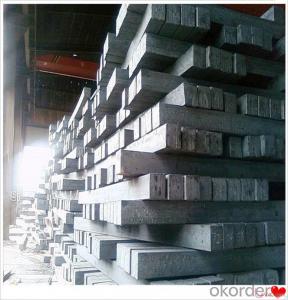

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: How are steel billets used in the manufacturing of tooling?

- Steel billets are an essential component in the manufacturing of tooling. Tooling refers to the process of designing and creating tools that are used in various industries for cutting, shaping, or forming materials. Steel billets are semi-finished products that are cast from molten steel and then hot rolled into various shapes and sizes. In the manufacturing of tooling, steel billets serve as the raw material from which the tool is formed. These billets are usually made from high-quality steel alloys that exhibit excellent strength, durability, and wear resistance properties. These characteristics are crucial for tooling applications as they ensure the longevity and performance of the tools. Once the steel billets are obtained, they undergo a series of processes to transform them into tooling components. The first step is to heat the billets to a specific temperature, typically above the recrystallization temperature, which makes the steel more malleable and easier to shape. This process is known as hot working. After heating, the steel billets are shaped into the desired form through various techniques such as forging, extrusion, or rolling. These methods allow the steel to be molded into complex shapes, such as dies or molds, which are commonly used in tooling applications. The shaping process ensures that the tooling components have the necessary dimensions, surface finish, and structural integrity to perform their intended function. Once the tooling components are shaped, they may undergo additional heat treatments to further enhance their mechanical properties. Processes like tempering, annealing, or hardening are commonly used to modify the steel's hardness, toughness, and resistance to wear. These treatments increase the tooling's lifespan and improve its performance in demanding manufacturing environments. Overall, steel billets play a crucial role in the manufacturing of tooling by serving as the starting material for shaping tooling components. The high-quality steel used in billets provides the necessary strength and durability required for tooling applications. By shaping, heat treating, and finishing these billets, manufacturers can create tooling that meets the specific needs of various industries, enabling efficient and precise cutting, shaping, and forming of materials.

- Q: Can steel billets be used in the production of medical equipment?

- Certainly, medical equipment can utilize steel billets. Renowned for its robustness, longevity, and resistance to deterioration, steel proves to be an optimal substance for fabricating diverse medical apparatus. Steel billets, the preliminary intermediate product in steel production, can undergo additional processing and molding to form precise components or parts indispensable for medical equipment. Such components encompass surgical instruments, implants, orthopedic devices, needles, and other medical implements. The mechanical attributes of steel and its capacity to endure sterilization procedures render it a fitting preference for manufacturing dependable and secure medical equipment.

- Q: What is the role of steel billets in the construction of offshore platforms?

- Steel billets play a crucial role in the construction of offshore platforms. These platforms are massive structures that are installed in the open sea to extract oil or gas from beneath the ocean floor. Due to the harsh environmental conditions and the need for utmost safety and durability, steel billets are widely used in their construction. One of the primary functions of steel billets is to provide the raw material for the fabrication of various components of offshore platforms. Billets are large, semi-finished steel products that are typically used as starting material for the production of other steel products. They are cast into a specific shape, usually a square or a rectangle, and have a solid cross-section. Offshore platforms require steel with exceptional strength, corrosion resistance, and impact toughness to withstand the challenging conditions they face, such as strong waves, harsh weather, and extreme temperatures. Steel billets are often made from high-strength alloyed steels, which offer superior mechanical properties and resistance to corrosion. These billets are then further processed to manufacture different structural elements of offshore platforms, including beams, columns, braces, and other support structures. These components must be able to support the weight of the platform itself, as well as withstand the forces generated by ocean waves, wind, and the extraction process. Moreover, steel billets are also used in the production of pipes and tubes, which are vital for transporting oil and gas from beneath the seabed to the platform or to the shore. These pipes need to be strong, durable, and resistant to corrosion to ensure the safe and efficient flow of hydrocarbons. In summary, steel billets serve as the building blocks for the construction of offshore platforms. They provide the raw material for fabricating various structural components, ensuring the strength, durability, and safety of these massive structures in the challenging offshore environment.

- Q: What are the different types of steel billet defects?

- There are several different types of steel billet defects that can occur during the manufacturing process. These defects can have an impact on the quality and performance of the final product. Some common types of steel billet defects include: 1. Surface defects: These are flaws or irregularities that occur on the outer surface of the billet. Examples include cracks, scale, and scratches. Surface defects can weaken the billet and reduce its overall strength. 2. Internal defects: These defects occur within the billet and are not visible on the surface. They can be caused by factors such as non-metallic inclusions, voids, or gas pockets. Internal defects can compromise the structural integrity of the billet and lead to failures or deformations. 3. Segregation: This defect refers to the uneven distribution of alloying elements within the billet. It can result in inconsistent mechanical properties across the billet, leading to variations in strength or hardness. 4. Pipe: Pipe defects occur in the center of the billet and are caused by the formation of a cavity during solidification. This defect can weaken the billet, making it more susceptible to cracking or other forms of failure. 5. Incomplete solidification: This defect occurs when the billet does not fully solidify during the casting process. It can lead to internal cracks or voids, reducing the overall quality and strength of the billet. 6. Surface decarburization: This defect occurs when the surface of the billet loses carbon during the heating or cooling process. It can result in reduced hardness and wear resistance in the final product. It is important for manufacturers to closely monitor and control the production process to minimize the occurrence of these defects. Various techniques such as quality control checks, heat treatment, and proper handling can help prevent or mitigate the impact of these defects on the final product.

- Q: Can steel billets be cold rolled?

- Steel billets cannot be cold rolled, as this process specifically involves reducing the thickness of a metal sheet or strip by passing it through a series of rollers at room temperature. Instead, steel billets are primarily utilized as raw material for producing steel bars, rods, and other long products through hot rolling. During hot rolling, the steel billets are heated to high temperatures and subsequently passed through rolling mills to achieve the desired shape and dimensions. Cold rolling is not appropriate for steel billets because it necessitates heating to enhance the steel's malleability and ability to deform, which cannot be achieved with solid, unheated billets.

- Q: What are the main factors affecting the surface finish of steel billets?

- The main factors affecting the surface finish of steel billets include the quality and cleanliness of the raw materials used, the temperature and pressure during the production process, the type and condition of the equipment used for processing, and the skill and expertise of the personnel involved in handling and finishing the billets. Additionally, factors such as the presence of impurities, chemicals, or contaminants, as well as the use of lubricants or surface treatments, can also impact the surface finish of steel billets.

- Q: What are the different methods of steel billet surface finishing?

- There are several methods of steel billet surface finishing that are commonly used in the industry. These methods include: 1. Shot blasting: Shot blasting is a common method used to clean and prepare steel billets for further processing. It involves propelling abrasive particles at high speeds onto the surface of the billets. This process removes any rust, scale, or impurities from the surface, resulting in a clean and smooth finish. 2. Grinding: Grinding is another method used to achieve a smooth and even surface finish on steel billets. It involves the use of abrasive wheels or belts to remove material from the surface of the billets. Grinding can be done manually or using automated machinery, depending on the requirements and size of the billets. 3. Polishing: Polishing is a process that is typically used to achieve a high-gloss, reflective finish on steel billets. It involves the use of polishing compounds and buffing wheels to smooth out the surface and enhance its appearance. Polishing is often used for decorative purposes or when a high-quality finish is required. 4. Acid pickling: Acid pickling is a method used to remove any oxide scale or rust from the surface of steel billets. It involves immersing the billets in an acid solution, such as hydrochloric acid, to dissolve the impurities. Acid pickling is an effective way to achieve a clean and uniform surface finish on steel billets. 5. Passivation: Passivation is a process that is often used to improve the corrosion resistance of steel billets. It involves the immersion of the billets in a passivating solution, typically a mixture of nitric acid and water, to remove any surface contaminants and promote the formation of a protective oxide layer. Passivation can help to prevent the formation of rust and extend the lifespan of the steel billets. Overall, the choice of method for steel billet surface finishing depends on the desired finish, the size and shape of the billets, and the specific requirements of the application. Each method has its own advantages and considerations, and it is important to carefully select the appropriate method to achieve the desired surface finish.

- Q: What are the main factors affecting the hardness of steel billets?

- The main factors affecting the hardness of steel billets are the carbon content, the alloying elements present in the steel, the cooling rate during the quenching process, and the heat treatment process employed.

- Q: What is the role of steel billets in the manufacturing of automotive transmission systems?

- Steel billets play a crucial role in the manufacturing of automotive transmission systems. These billets are raw material forms of steel that are used as a starting point for shaping and forming various components of the transmission system. One of the main uses of steel billets in the manufacturing process is for the production of gears, shafts, and other critical transmission components. These billets are forged or machined to create the desired shape, strength, and dimensional accuracy required for these components. The use of steel billets ensures that these parts possess the necessary strength, durability, and resistance to wear and tear, which are essential for the proper functioning of the transmission system. Additionally, steel billets are also utilized in the production of transmission casings. These casings provide the housing and protection for the internal components of the transmission system. Steel billets are cast or molded into the desired shape to create these casings, ensuring they have the necessary strength and rigidity to withstand the forces and stresses experienced by the transmission system. Moreover, the use of steel billets allows for the customization and optimization of the transmission system components. Manufacturers can choose specific grades of steel billets based on their desired properties, such as hardness, toughness, or corrosion resistance. This flexibility enables the production of transmission systems that meet the specific requirements of different automotive applications, whether it be for high-performance vehicles or heavy-duty trucks. In summary, steel billets are integral to the manufacturing of automotive transmission systems. They provide the raw material from which gears, shafts, casings, and other components are formed. Steel billets ensure the strength, durability, and customization potential necessary to create reliable and efficient transmission systems for various automotive applications.

- Q: What are the different types of steel billet surface defects?

- There are several different types of steel billet surface defects that can occur during the manufacturing process. These defects can affect the quality and performance of the steel, and it is important to identify and address them to ensure the integrity of the final product. 1. Scale: Scale is a common defect that occurs as a result of oxidation during the heating and rolling process. It appears as a thin layer of iron oxide on the surface of the billet and can be easily removed through descaling processes. 2. Cracks: Cracks are another common defect that can occur on the surface of steel billets. They can be caused by several factors such as uneven cooling, excessive stress, or improper handling. Cracks can lead to weakened structural integrity and should be repaired or the affected billets discarded. 3. Pitting: Pitting is a defect characterized by small, shallow depressions or pits on the surface of the billet. It can be caused by a variety of factors including impurities in the steel, improper cooling, or corrosion. Pitting can lead to reduced strength and increased susceptibility to corrosion. 4. Lamination: Lamination defects occur when there are layers or separation within the billet caused by poor bonding during the manufacturing process. This defect can compromise the mechanical properties of the steel and may result in failure under stress. 5. Inclusions: Inclusions are non-metallic substances that become trapped within the billet during the manufacturing process. They can include slag, oxides, or other impurities. Inclusions can weaken the steel and reduce its ductility, making it more prone to cracking or breaking. 6. Scratches: Scratches are superficial defects that can occur during handling or transportation of the billets. While they may not greatly affect the overall structural integrity of the steel, they can lead to localized stress concentrations and potential failure in certain applications. 7. Decarburization: Decarburization is a defect that occurs when the surface of the billet loses its carbon content during the heating process. This can lead to reduced hardness and strength in the affected area, affecting the performance of the steel. It is important for manufacturers and inspectors to be aware of these different types of steel billet surface defects to ensure the production of high-quality steel products. Regular inspections, quality control measures, and appropriate corrective actions can help minimize and address these defects to ensure the desired performance and longevity of the steel.

Send your message to us

Steel Billet for Rebar Steel Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords