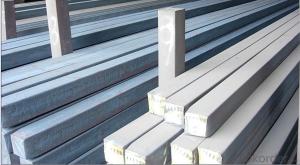

Prime Q275 135mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 135mm Square Alloy Steel Billet

Description of Prime Q275 135mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 135mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 135mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 135mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 135mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What is the role of steel billets in the construction of stadiums and arenas?

- Steel billets play a crucial role in the construction of stadiums and arenas. These billets, which are essentially semi-finished steel products, serve as the raw material for various structural components used in the construction process. One of the primary applications of steel billets in stadium and arena construction is for the fabrication of steel beams and columns. These structural elements provide the necessary support and stability to the overall structure. Steel billets are first heated and then passed through rolling mills to acquire the desired shape and size required for these beams and columns. Moreover, steel billets are also used in the production of steel reinforcing bars, commonly known as rebars. These rebars are used to reinforce the concrete structures within stadiums and arenas, such as foundations, walls, and floors. The combination of steel and concrete enhances the structural integrity and load-bearing capacity of these structures, making them capable of withstanding heavy loads, vibrations, and external forces. Additionally, steel billets are utilized in the construction of roof trusses and frames, which provide support for the stadium or arena's roofing system. These steel components offer the necessary strength and durability to withstand the weight of the roof, while also ensuring the overall stability of the structure. Furthermore, steel billets are employed in the production of seating structures, staircases, handrails, and other architectural elements within stadiums and arenas. These components not only contribute to the overall aesthetics of the venue but also provide safety and comfort to spectators. In summary, steel billets are indispensable in the construction of stadiums and arenas. They are transformed into various structural and architectural components that provide strength, stability, and durability to the overall structure. By utilizing steel billets, stadiums and arenas can be built to withstand the demands of large crowds, harsh weather conditions, and the test of time.

- Q: What are the different types of steel billet rolling mill defects?

- During the rolling process of steel billet in a rolling mill, various types of defects may occur. These defects can impact the final product's quality and performance and can have different causes. Some commonly observed defects include: 1. Surface defects: Scratches, cracks, pits, and scale are visible defects that can occur on the surface of the rolled billet. These defects can be caused by improper handling, insufficient lubrication, or excessive rolling pressures. 2. Shape defects: Deviations from the desired shape of the billet, such as bowing, twisting, or excessive tapering, are referred to as shape defects. Uneven cooling, improper alignment of the rolling mill, or incorrect rolling parameters can cause these defects. 3. Internal defects: Internal defects are not visible on the surface but can impact the structural integrity of the billet. Segregation, porosity, and inclusions are examples of internal defects. The presence of impurities in the raw material, improper heating or cooling, or inadequate quality control measures can cause these defects. 4. Dimensional defects: Deviations from the desired dimensions of the billet, such as variations in length, width, or thickness, are called dimensional defects. Improper calibration of the rolling mill, incorrect rolling parameters, or inadequate quality control measures can cause these defects. 5. Metallurgical defects: Metallurgical defects occur due to improper metallurgical processes during rolling. Grain size variations, improper grain flow, or undesirable microstructure are examples of metallurgical defects. Improper temperature control, inadequate alloying, or insufficient heat treatment can cause these defects. To ensure the production of high-quality steel billets, it is crucial for steel billet rolling mills to implement proper quality control measures. Regular inspections, testing, and monitoring during the rolling process can help identify and rectify these defects, thus minimizing their occurrence.

- Q: Can steel billets be used in the production of railway infrastructure?

- Yes, steel billets can be used in the production of railway infrastructure. Steel billets are semi-finished products that are typically used as raw material in the manufacturing of various steel products. In the case of railway infrastructure, steel billets can be further processed and shaped into different components such as rails, sleepers, and fasteners. Rails, the tracks on which trains run, are usually made from steel billets. These billets are heated and passed through a rolling mill to form the desired rail profile. The resulting rail is then further processed to meet specific requirements such as strength, durability, and resistance to wear and fatigue. Similarly, steel billets can also be used in the production of sleepers, which are the supporting structures that hold the rails in place. Sleepers are typically made from prestressed concrete or steel, and steel billets can be used as the raw material for manufacturing steel sleepers. Additionally, steel billets can be used in the production of various fasteners that are essential for railway infrastructure. These include rail clips, bolts, nuts, and washers, which are used to securely fasten rails to sleepers and other components. Overall, steel billets play a crucial role in the production of railway infrastructure. They provide the necessary raw material for manufacturing rails, sleepers, and fasteners, thereby contributing to the construction and maintenance of railway tracks, bridges, and other essential infrastructure elements.

- Q: How are steel billets transported internationally?

- Depending on factors such as distance, quantity, and urgency, steel billets are transported internationally by various means. Popular methods include shipping, rail, and road transportation. For long-distance international transport, shipping is the preferred choice. Steel billets are loaded into shipping containers, typically 20-foot or 40-foot in size, and secured to prevent movement during transit. These containers are then transported by cargo ships, which offer large storage capacities and efficient transportation over vast distances. Designed to protect the steel billets from external elements like moisture and corrosion, shipping containers ensure their integrity upon arrival. Rail transport is also commonly used for international shipments, especially to destinations connected by rail networks. Steel billets are loaded onto railcars, either in open-top or covered wagons depending on requirements and weather conditions. Rail transportation is favored for its cost-effectiveness, ability to handle large volumes, and access to landlocked regions. For shorter distances or urgent deliveries, road transportation is employed. Steel billets are loaded onto flatbed trucks or trailers, securely fastened to prevent any movement, and transported directly to their destination. Road transport offers flexibility, allowing delivery to locations where other modes may face limitations. Regardless of the transportation mode, international shipments of steel billets must have proper documentation, including customs clearance, bill of lading, and other relevant paperwork. These ensure compliance with international trade regulations, smooth border crossings, and timely delivery of the steel billets to their destination.

- Q: Can steel billets be used in the production of jewelry?

- Due to its composition and properties, steel billets are usually not utilized in jewelry production. Steel, which is primarily made up of iron and carbon and contains additional elements like manganese, chromium, and nickel, possesses strength and durability that make it well-suited for various industrial applications, but not for crafting jewelry. In contrast, jewelry is typically crafted from precious metals like gold, silver, and platinum, which possess unique characteristics that make them suitable for adornment. These metals are easily shaped and molded into intricate designs due to their malleability. Moreover, they have a lustrous appearance and are resistant to tarnishing or corrosion. On the other hand, steel is much harder and less malleable compared to precious metals. It cannot be easily manipulated into the delicate and intricate shapes required for jewelry making. Additionally, steel has a dull gray color that does not offer the desired aesthetic appeal in jewelry. While it is technically possible to create jewelry using steel billets, it is not a common practice due to the aforementioned reasons. Steel is primarily utilized in industries where its high strength and durability are necessary, such as construction, automotive, and machinery manufacturing.

- Q: How are steel billets used in the production of hydraulic components?

- Hydraulic components production heavily relies on steel billets, which serve as an essential raw material. These semi-finished steel forms act as the initial step in manufacturing various hydraulic parts. To commence, steel billets are subjected to high temperatures to enhance their malleability. This process, known as hot rolling, facilitates easy shaping and formation of the billets into the desired hydraulic component. Subsequently, the heated billets are passed through a series of rollers, resulting in the desired size and shape, such as bars, rods, or tubes. After shaping, the steel billets undergo further machining procedures to fabricate specific hydraulic components. For instance, they may be cut, drilled, or threaded to create pistons, cylinders, valve bodies, or other essential parts utilized in hydraulic systems. The utilization of steel billets in hydraulic component production offers numerous advantages. Firstly, steel is renowned for its strength and durability, making it an ideal material for hydraulic applications where components endure high pressure and heavy loads. Additionally, steel's exceptional corrosion resistance ensures the longevity of hydraulic components, even in harsh operating conditions. Moreover, steel billets facilitate precise dimensional control throughout the manufacturing process. This guarantees that the hydraulic components meet the required specifications and can flawlessly integrate into hydraulic systems, without compromising performance. In conclusion, steel billets play a pivotal role in hydraulic component production. By commencing with these semi-finished steel forms, manufacturers can fabricate high-quality, durable, and precisely engineered parts, which are crucial for the efficient functioning of hydraulic systems.

- Q: What is the role of steel billets in the manufacturing of storage tanks?

- Steel billets play a crucial role in the manufacturing of storage tanks. These billets serve as the primary raw material for the construction of the tank's structural framework. They are essentially semi-finished steel products that are cast into a specific shape and size, typically in a rectangular or square form. The primary reason for using steel billets in the manufacturing of storage tanks is their exceptional strength and durability. Steel is renowned for its high tensile strength, which allows the tank to withstand the immense pressure and weight of the stored contents. Additionally, steel is resistant to corrosion, making it an ideal material for storage tanks that may hold various liquids or gases. Steel billets are also preferred for their malleability and versatility. They can be easily molded and welded into the desired shape, allowing for the customization of storage tanks to meet specific requirements. The flexibility of steel billets enables the construction of tanks of various sizes and capacities, accommodating different storage needs in industries such as oil and gas, chemical processing, water treatment, and many others. Furthermore, steel billets offer cost-effectiveness in the manufacturing process. The abundance of steel as a raw material and its recyclability contribute to lower production costs, making steel tanks a more economical choice compared to tanks made from other materials. Moreover, the longevity of steel tanks reduces maintenance and replacement costs over time, ensuring a higher return on investment for industries relying on storage tanks. In conclusion, steel billets play a vital role in the manufacturing of storage tanks due to their strength, durability, corrosion resistance, malleability, and cost-effectiveness. These billets form the core framework of the tanks, providing the necessary structural integrity to safely contain and store various liquids or gases. By utilizing steel billets, industries can rely on robust and reliable storage solutions that meet their specific storage requirements.

- Q: What are the different surface treatments applied to alloy steel billets?

- Some of the different surface treatments applied to alloy steel billets include hot rolling, cold drawing, peeling, grinding, and polishing. These treatments are used to improve the surface finish, dimensional accuracy, and overall quality of the billets.

- Q: What are the main factors affecting the corrosion resistance of alloy steel billets?

- The corrosion resistance of alloy steel billets is influenced by several key factors. Firstly, the composition of the alloy steel plays a crucial role in determining its resistance to corrosion. Alloy steels containing a higher percentage of elements such as chromium, nickel, and molybdenum tend to have enhanced corrosion resistance compared to steels with lower alloy content. Secondly, the presence of protective surface coatings or finishes can significantly improve the corrosion resistance of alloy steel billets. Various coatings, such as zinc or epoxy, act as a barrier between the metal surface and the corrosive environment, preventing the steel from coming into direct contact with corrosive agents. Additionally, the manufacturing process used to produce alloy steel billets can impact their corrosion resistance. Proper heat treatment and quenching processes can enhance the microstructure of the alloy, creating a more corrosion-resistant material. The environment in which the alloy steel billets are exposed is another crucial factor. Factors such as temperature, humidity, pH levels, and the presence of corrosive substances can all influence the corrosion resistance of the alloy steel billets. For example, exposure to high temperatures or acidic environments can accelerate corrosion, while exposure to dry or neutral conditions may have a minimal impact on corrosion resistance. Lastly, the design and maintenance of structures or equipment made from alloy steel billets can affect their corrosion resistance. Proper design considerations, such as avoiding sharp corners or crevices where moisture can accumulate, can help minimize the risk of corrosion. Regular inspection, cleaning, and maintenance can also help prevent corrosion by identifying and addressing any issues promptly. In conclusion, the main factors affecting the corrosion resistance of alloy steel billets include the composition of the steel, the presence of protective coatings, the manufacturing process, the environmental conditions, and the design and maintenance practices. By considering these factors, manufacturers and users can ensure that alloy steel billets exhibit optimal corrosion resistance in various applications.

- Q: What is the billet price in China today?

- In the short term is still the main shock, the domestic price rise compared to the previous 10 yuan / ton, the price is not the same in each region, so you still have to carefully check the price, from the upstream iron ore, domestic ore prices stabilize, without much change, with the real estate back to temperature.

Send your message to us

Prime Q275 135mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords