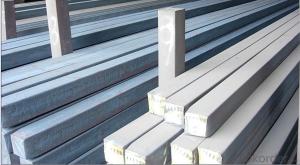

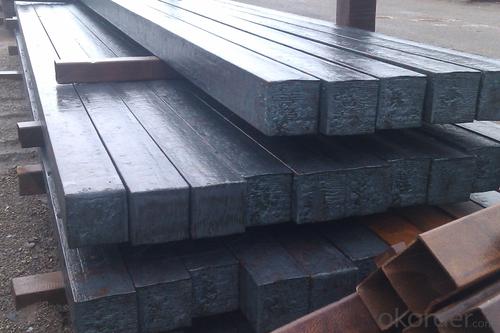

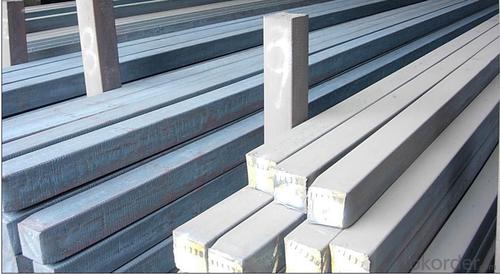

Prime Q275 115mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 115mm Square Alloy Steel Billet

Description of Prime Q275 115mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 115mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 115mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 115mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 115mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the environmental impacts of steel billet production?

- The production of steel billets, which are semi-finished steel products, can have various environmental impacts. One significant environmental impact is the emission of greenhouse gases during the steel manufacturing process. The production of steel billets involves the melting of iron ore, which releases carbon dioxide (CO2) into the atmosphere. CO2 is a major contributor to global warming and climate change. Another environmental impact of steel billet production is the consumption of natural resources. The steel industry requires significant amounts of water and energy to produce billets. The extraction and processing of raw materials, such as iron ore and coal, can also lead to habitat destruction and disruption of ecosystems. Furthermore, the production of steel billets can result in air and water pollution. The combustion of fossil fuels during the manufacturing process releases various pollutants, including sulfur dioxide (SO2) and nitrogen oxides (NOx), which contribute to acid rain and respiratory problems. Additionally, the discharge of wastewater from steel production can contain heavy metals and other contaminants, which can pollute rivers and harm aquatic life. Steel billet production also generates solid waste, such as slag and dust, which can pose challenges for waste management. These waste materials may contain toxic substances and require proper handling and disposal to prevent environmental contamination. To mitigate the environmental impacts of steel billet production, various measures can be taken. The adoption of cleaner technologies, such as energy-efficient furnaces and recycling processes, can help reduce energy consumption and emissions. Implementing rigorous environmental management systems and investing in pollution control technologies can also minimize air and water pollution. Additionally, promoting the use of recycled steel and sustainable sourcing of raw materials can help conserve natural resources and reduce the environmental footprint of steel billet production.

- Q: How are steel billets used in the production of conveyor systems?

- Steel billets play a crucial role in the production of conveyor systems, as they are utilized to form the main structural framework. To achieve the desired shape, the billets undergo a process called hot rolling, which involves heating them and passing them through a series of rollers. This results in the transformation of the billets into long, slender bars with a consistent cross-sectional shape. Once shaped, the steel billets are further processed to create various components for the conveyor system. These components include conveyor frames, support beams, brackets, and other structural elements that provide stability and strength to the system. Steel billets are well-suited for this purpose due to their high tensile strength and durability. Apart from structural components, steel billets are also utilized in the production of conveyor rollers. These rollers are essential for facilitating the movement of materials along the conveyor system. The steel billets are machined and formed into cylindrical shapes, which are then fitted with bearings to ensure smooth rotation. The rollers are then installed at regular intervals along the conveyor, enabling efficient and continuous material handling. Furthermore, steel billets are often employed in the manufacturing of conveyor belts. The billets are processed into thin sheets, which are then coated with materials such as rubber or fabric to provide grip and durability. These belts bear the load of the materials being transported and are designed to withstand heavy usage and harsh environments. In conclusion, steel billets are vital in the production of conveyor systems, providing essential structural support as well as components like rollers and belts. Their strength, durability, and versatility make them an ideal choice for constructing conveyor systems that can handle heavy loads and ensure efficient material handling in various industries.

- Q: What are the safety precautions to be taken while handling steel billets?

- Some safety precautions to be taken while handling steel billets include wearing appropriate personal protective equipment (PPE) such as gloves, safety goggles, and steel-toed boots to protect against potential injuries. It is important to ensure proper lifting techniques are used, utilizing mechanical aids if necessary, to avoid strains or back injuries. Additionally, maintaining a clean and organized work area can help minimize tripping hazards and potential accidents. Regular inspection and maintenance of equipment, such as cranes and forklifts, is essential to ensure safe handling of the steel billets.

- Q: Can steel billets be used for making musical instruments?

- Yes, steel billets can be used for making musical instruments. While traditional musical instruments are often made from materials such as wood or brass, steel can also be used to create unique and modern instruments. Steel's strength and durability make it ideal for certain instruments, such as steel drums or steel guitars. Additionally, steel's versatility allows for the creation of intricate designs and shapes that can produce a wide range of sounds. However, it is important to note that the specific characteristics and properties of the steel used, such as its composition and thickness, will greatly impact the sound and quality of the instrument. Therefore, careful consideration and experimentation may be required to achieve the desired musical tones and effects when using steel billets for instrument making.

- Q: What are the different types of steel billet extrusion processes?

- The manufacturing industry utilizes various steel billet extrusion processes, each with its own distinct characteristics. These processes employ high pressure to shape solid steel billets into desired profiles or shapes. 1. The most frequently employed method is direct extrusion. This process involves placing the billet within a container, commonly referred to as a "container" or "container die." The container possesses a small opening, known as a "die," through which the billet is propelled using a ram or piston. The billet is then forced through the die, resulting in the formation of the desired shape. 2. Another technique, indirect extrusion, involves a stationary container die. The billet is pushed through the die using a punch or ram. The billet is positioned inside a hollow chamber called a "container" or "container die," featuring a smaller opening at one end. Pressure is applied to the billet using the punch, compelling it to flow through the die and adopt the desired profile. 3. Impact extrusion shares similarities with direct extrusion but incorporates a specially designed punch. This punch strikes the billet with a significant impact force, causing it to flow and take on the shape of the die. Impact extrusion is frequently utilized to produce small, intricate shapes with thin walls. 4. Hydrostatic extrusion employs a sealed chamber filled with a pressurized fluid, typically oil or water, in which the billet is placed. The fluid pressure is utilized to force the billet to flow through the die and acquire the desired shape. Hydrostatic extrusion is commonly employed for the production of complex shapes with high precision. 5. Cold extrusion is performed at room temperature without the need for heating the steel billet. This method is often used to produce small, intricate parts with high dimensional accuracy. It offers a cost-effective approach, enabling the production of parts with excellent surface finish. The selection of a specific steel billet extrusion process depends on various factors, including the desired shape, size, material properties, and production requirements. Each process has its own advantages and limitations.

- Q: How are steel billets used in the manufacturing of hydraulic cylinders?

- Steel billets are a fundamental part of hydraulic cylinder production, serving as the initial material for the manufacturing process. These billets, which are cylindrical shapes made of raw steel, are essential in various industries such as construction, mining, and automotive, as they provide linear force and motion. To create hydraulic cylinders, steel billets are heated and shaped using specialized machinery like hydraulic presses or hot rolling mills. This process, known as forging, involves subjecting the billets to immense pressure and heat to reshape them as required. Once forged, the steel billets are machined and precisely cut to form the necessary features, including the bore and mounting holes, essential for the hydraulic cylinder's functionality. This machining process ensures that the cylinder has the correct dimensions and tolerances. Following machining, the steel billets undergo heat treatment to enhance their mechanical properties. This involves heating the billets to specific temperatures and rapidly cooling them, resulting in improved strength, hardness, and resistance to wear and fatigue. After undergoing forging, machining, and heat treatment, the steel billets are ready for assembly into hydraulic cylinders. The various components like pistons, piston rods, seals, and bearings are carefully fitted together to create fully functioning hydraulic cylinders. In summary, steel billets play a vital role in the production of hydraulic cylinders. Through forging, machining, and heat treatment, these billets are transformed into components with the desired properties. The resulting hydraulic cylinders are then utilized in diverse applications, delivering efficient and reliable linear force and motion.

- Q: Can steel billets be used in the production of jewelry?

- Steel billets are typically not used in the production of jewelry due to their composition and properties. Steel is an alloy primarily composed of iron and carbon, with additional elements such as manganese, chromium, and nickel. This composition gives steel its strength and durability, making it ideal for various industrial applications, but not for jewelry production. Jewelry is often crafted from precious metals like gold, silver, and platinum, which possess unique characteristics that make them suitable for adornment. These metals are malleable, meaning they can be easily shaped and molded into intricate designs. Additionally, they have a lustrous appearance and are resistant to tarnishing or corrosion. Steel, on the other hand, is much harder and less ductile compared to precious metals. It cannot be easily manipulated into delicate and intricate shapes required for jewelry making. Furthermore, steel has a dull gray color, which does not provide the desired aesthetic appeal in jewelry. While it is technically possible to create jewelry using steel billets, it is not a common practice due to the aforementioned reasons. Steel is primarily used in industries where its high strength and durability are necessary, such as construction, automotive, and machinery manufacturing.

- Q: What are the different types of casting processes used for shaping steel billets?

- There are several types of casting processes used for shaping steel billets. Some of the common ones include continuous casting, ingot casting, and centrifugal casting. Continuous casting involves pouring molten steel into water-cooled molds to create a continuous strand of solidified steel. Ingot casting involves pouring molten steel into individual molds to create solidified ingots. Centrifugal casting utilizes centrifugal force to pour molten steel into a rotating mold, resulting in a cylindrical shape. These casting processes offer different advantages and are used depending on the specific requirements of the steel billet shaping process.

- Q: What are the advantages of using steel billets in manufacturing?

- There are several advantages of using steel billets in manufacturing. Firstly, steel billets are highly versatile and can be easily shaped into various forms, making them suitable for a wide range of applications. Secondly, steel billets have excellent strength and durability, ensuring the final products made from them are strong and long-lasting. Additionally, steel billets have good resistance to corrosion and can withstand high temperatures, making them ideal for use in harsh environments. Lastly, steel billets are readily available and cost-effective, making them a preferred choice for many manufacturers.

- Q: What are the different types of surface finish inspection methods for steel billets?

- There are several different types of surface finish inspection methods that can be used for steel billets. These methods are crucial in determining the quality and suitability of the billets for further processing or use. Some of the common surface finish inspection methods for steel billets include: 1. Visual inspection: This is a basic method where the surface of the billet is visually examined for any irregularities, such as cracks, pits, scratches, or any other surface imperfections. It is a quick and cost-effective method but may not be able to detect subtle defects. 2. Magnetic particle inspection: This method involves magnetizing the surface of the billet and applying fine iron particles on it. Any surface cracks or defects will cause a leakage of magnetic field, attracting the iron particles and making them visible under appropriate lighting conditions. 3. Dye penetrant inspection: In this method, a liquid dye is applied to the surface of the billet. The dye penetrates into any surface cracks or defects, and after a certain period, excess dye is removed. A developer is then applied, which draws out the dye from the cracks and defects, making them visible. 4. Ultrasonic testing: This method utilizes high-frequency sound waves that are transmitted through the steel billet. The waves are reflected back when they encounter any surface irregularities, such as cracks or voids. By analyzing the time taken for the waves to return, the size and depth of the defects can be determined. 5. Eddy current testing: This non-destructive testing method uses electromagnetic induction to detect surface defects. An alternating current is passed through a coil, creating a magnetic field. When the coil is near the surface of the billet, any defects will disrupt the magnetic field, causing a change in the electrical impedance. This change is measured and analyzed to identify surface defects. Each of these inspection methods has its advantages and limitations, and the choice of method depends on the specific requirements, the size and shape of the billet, and the level of accuracy desired. By employing these surface finish inspection methods, manufacturers can ensure the quality and reliability of the steel billets before they are further processed or used in various applications.

Send your message to us

Prime Q275 115mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords