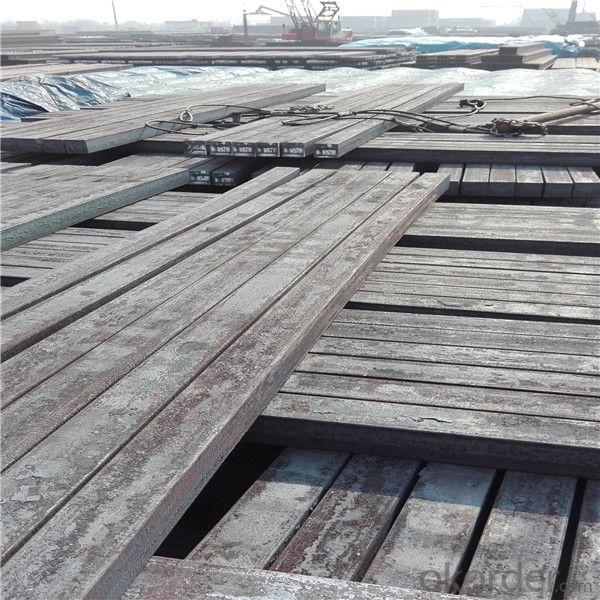

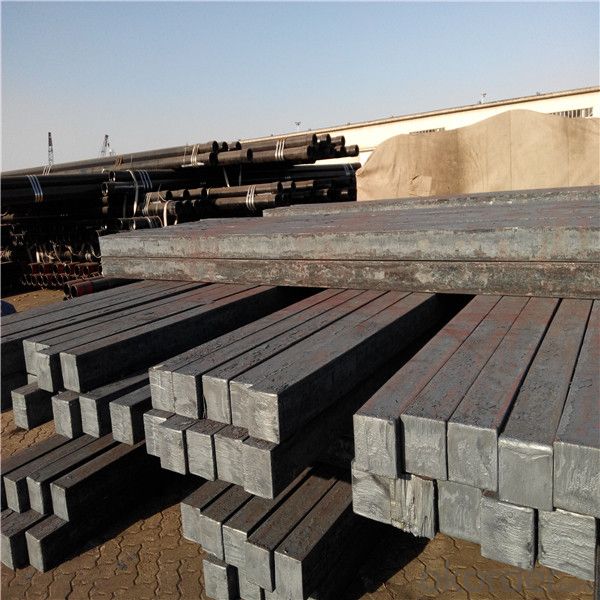

Prime Square Steel Billet 150x150mm 165x165mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19684 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the

support foundation pile manufacturing.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Other Specifications

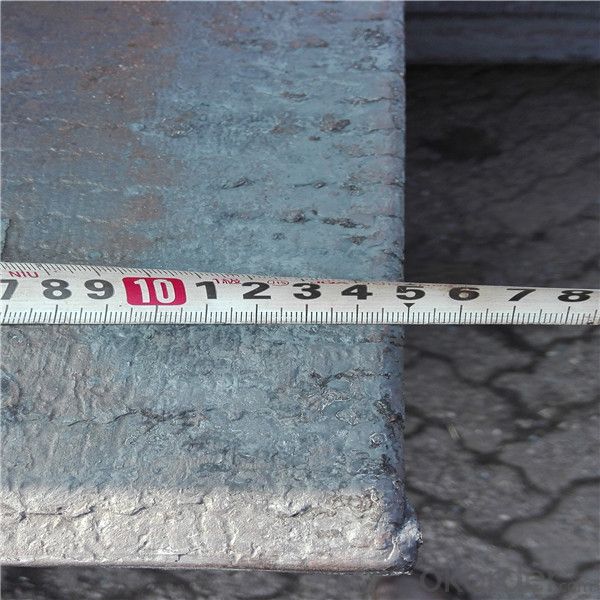

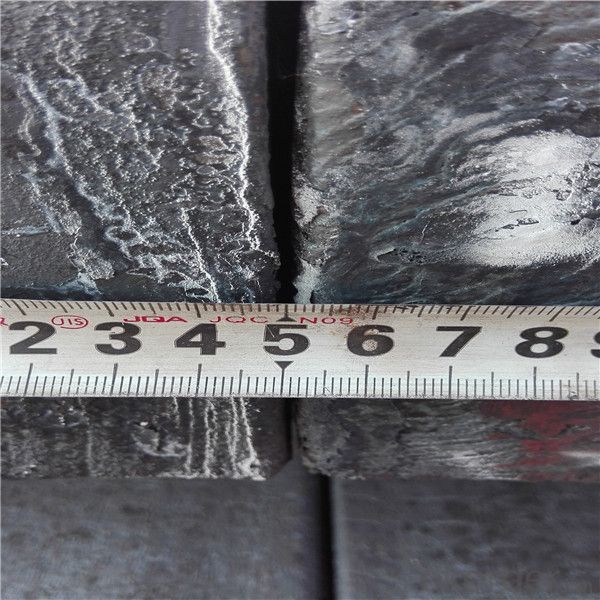

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the main types of steel billet rolling mills?

- Various types of steel billet rolling mills exist, each possessing unique characteristics and functionalities to cater to the diverse requirements of different industries. 1. Two-high rolling mills: These mills comprise two horizontally mounted rolls rotating in opposite directions. Two-high mills are commonly utilized for shaping and reducing the thickness of steel billets. They boast a relatively simple design and are suitable for light to medium-duty applications. 2. Three-high rolling mills: Three-high mills consist of three rolls arranged vertically in a triangular configuration. The upper and lower rolls are driven, while the middle roll remains idle and adjustable. This design allows for greater flexibility in shaping and reducing the dimensions of the billet. Three-high mills are often employed to produce high-quality finished products with precise dimensions and surface finishes. 3. Four-high rolling mills: Four-high mills possess four rolls, including two small diameter work rolls and two larger diameter backup rolls. The work rolls are driven, while the backup rolls provide support and adjust the billet's thickness. Four-high mills are highly versatile and can be utilized for a wide range of applications, encompassing both hot and cold rolling processes. 4. Cluster mills: Cluster mills consist of multiple small-diameter rolls arranged in a cluster. These rolls collaborate to reduce the billet's thickness and shape it into the desired form. Cluster mills are commonly utilized to produce high-precision products such as wires and thin strips. 5. Steckel mills: Steckel mills are specialized rolling mills designed for the production of heavy-gauge plates and strips. They incorporate a combination of a reversible rolling mill and a continuous casting machine. Steckel mills are renowned for their high productivity and the capability to manufacture a wide array of steel products with excellent surface quality. Each type of steel billet rolling mill boasts specific advantages and is suitable for particular applications. The selection of a mill depends on factors including the desired final product, required dimensions, production volume, and budgetary limitations.

- Q: What are the different methods of steel billet inspection?

- There are several different methods of steel billet inspection that are commonly used in the manufacturing industry. These methods are employed to ensure the quality and integrity of the steel billets before they are further processed into various end products. Some of the most common methods of steel billet inspection include: 1. Visual Inspection: This is the simplest and most basic method of inspection, where trained inspectors visually examine the billets for any surface defects, such as cracks, pits, or any other irregularities. This method is typically used as an initial screening process before more advanced inspection techniques are employed. 2. Ultrasonic Testing: Ultrasonic testing utilizes high-frequency sound waves to detect any internal defects or inconsistencies within the steel billets. This method involves the use of a transducer that emits sound waves into the billet, and the reflected waves are analyzed to identify any flaws or abnormalities. Ultrasonic testing is effective in detecting internal defects like voids, inclusions, or cracks. 3. Magnetic Particle Inspection: This method is particularly useful for detecting surface and near-surface defects in steel billets. It involves applying a magnetic field to the billet and then applying iron particles to the surface. The particles will cluster around any magnetic leakage caused by surface cracks or defects, making them easily visible to the inspector. 4. Eddy Current Testing: Eddy current testing is a non-destructive method used to detect surface and near-surface defects in conductive materials, including steel billets. It involves passing an alternating current through a coil, creating an electromagnetic field. Any changes in the electromagnetic field caused by defects in the billet's surface are detected and analyzed, allowing for the identification of flaws. 5. X-ray Inspection: X-ray inspection is a widely used method for inspecting steel billets. It involves passing X-rays through the billet and capturing the resulting image on a film or digital detector. This method is highly effective in detecting both internal and external defects, such as cracks, voids, inclusions, or segregation. These are just a few of the commonly employed methods of steel billet inspection. Each method has its advantages and limitations, and the choice of inspection technique depends on factors such as the type of defect being targeted, the size and shape of the billets, and the specific requirements of the end product. By utilizing a combination of these inspection methods, manufacturers can ensure the quality and reliability of the steel billets they produce.

- Q: What are the potential applications of steel billets in the medical aftermarket?

- The medical aftermarket offers a wide range of potential applications for steel billets. One important application is the manufacture of surgical instruments, such as scalpels, forceps, scissors, and orthopedic implants. Steel billets are capable of producing high-quality and durable surgical instruments due to the strength and corrosion resistance of steel. Furthermore, steel billets are also useful in the production of medical equipment and devices. For instance, they can be used to create components for X-ray machines, CT scanners, and MRI machines. The excellent conductivity and high strength-to-weight ratio of steel make it a suitable choice for these demanding applications. In addition, steel billets can be utilized in the manufacturing of medical furniture and fixtures. Steel is commonly employed in the construction of hospital beds, examination tables, and cabinets due to its durability and ease of maintenance. Steel billets can provide the necessary raw material for the production of these essential medical items. Moreover, steel billets can also be employed in the fabrication of prosthetics and orthotics. These devices often require materials that are both strong and lightweight to ensure proper functionality and comfort for patients. Steel billets can be processed into various shapes and sizes to create prosthetic limbs, braces, and other orthopedic devices. In summary, the diverse and crucial potential applications of steel billets in the medical aftermarket cannot be underestimated. From surgical instruments to medical equipment, furniture, and prosthetics, steel billets possess the necessary qualities of strength, durability, and corrosion resistance to meet the demanding requirements of the medical industry.

- Q: Can steel billets be used in the production of oil and gas equipment?

- Steel billets have the capability to be utilized in the manufacturing process of oil and gas equipment. These semi-finished metal products, known as steel billets, are frequently employed as raw materials for the production of various industrial goods, including oil and gas equipment. They can undergo further treatment through hot rolling or forging to create distinct components like pipes, valves, flanges, and fittings, all of which are vital for the oil and gas industry. Given its robustness and resilience, steel is an ideal material for enduring the demanding conditions and high pressures encountered in oil and gas operations. Moreover, steel billets can be tailored to meet specific requirements, such as corrosion resistance, heat resistance, and mechanical properties, ensuring that the final product is suitable for its intended application within the oil and gas sector.

- Q: How are steel billets used in the production of rebar?

- Steel billets are used as the primary raw material in the production of rebar. These billets are heated and then passed through a series of rollers to shape them into long, thin rods. The resulting rebar is widely used in construction and infrastructure projects to reinforce concrete structures and provide added strength and durability.

- Q: How do steel billets contribute to the manufacturing of HVAC systems?

- Steel billets are used in the manufacturing of HVAC systems as they provide the raw material required for fabricating various components such as ductwork, heating coils, and air conditioning units. Billets are melted down and then shaped into the desired form, allowing manufacturers to create durable and sturdy components that can withstand the demanding conditions of HVAC systems. Additionally, steel billets offer excellent thermal conductivity, allowing for efficient heat transfer within the system, ultimately contributing to the overall performance and energy efficiency of HVAC systems.

- Q: What are the different surface treatments applied to stainless steel billets?

- There are several different surface treatments that can be applied to stainless steel billets to enhance their appearance and improve their corrosion resistance. Some of the most common surface treatments include: 1. Pickling: This process involves immersing the stainless steel billets in a bath of acid, such as nitric or hydrofluoric acid, to remove any scale or oxide layers that may have formed during the manufacturing process. Pickling helps to restore the stainless steel's original finish and provides a clean, smooth surface. 2. Passivation: Passivation is a chemical process that is used to enhance the corrosion resistance of stainless steel. It involves immersing the billets in an oxidizing solution, typically a nitric acid bath, to remove any embedded iron or other contaminants from the surface. Passivation forms a thin oxide layer on the surface of the stainless steel, which helps to prevent corrosion and maintain the material's integrity. 3. Electropolishing: This is an electrochemical process that is used to remove a thin layer of material from the surface of the stainless steel billets. By passing an electric current through the billets while they are immersed in an electrolyte solution, the surface is smoothed and any surface defects or impurities are removed. Electropolishing not only improves the appearance of the stainless steel, but also enhances its corrosion resistance and makes it easier to clean. 4. Grinding and polishing: These mechanical processes involve using abrasive materials to remove any imperfections or surface irregularities from the stainless steel billets. Grinding is typically done using a coarse abrasive wheel, while polishing uses progressively finer abrasives to achieve a smooth, reflective surface. Grinding and polishing can be used to achieve a variety of finishes, ranging from a brushed or satin finish to a mirror-like polished finish. These different surface treatments can be used individually or in combination to achieve the desired appearance and performance characteristics for stainless steel billets in various applications.

- Q: What are the different surface treatments applied to alloy steel billets?

- There are several different surface treatments that can be applied to alloy steel billets to enhance their properties and improve their performance. One common surface treatment is shot blasting, which involves bombarding the surface of the billets with small metal or ceramic particles at high velocity. This process helps to remove any impurities or contaminants on the surface, creating a clean and uniform surface finish. Shot blasting also promotes adhesion of subsequent coatings or treatments that may be applied to the billets. Another surface treatment is pickling, which involves immersing the billets in an acid solution to remove oxides and scale from the surface. This process helps to improve the surface quality and removes any surface defects, preparing the billets for further processing or treatments. A popular surface treatment for alloy steel billets is heat treatment, which involves subjecting the billets to controlled heating and cooling processes to alter their microstructure and improve their mechanical properties. Heat treatment can be used to increase the hardness, strength, and toughness of the billets, making them more suitable for specific applications. Additionally, alloy steel billets can be coated with various protective coatings to enhance their corrosion resistance and improve their durability. Common coating techniques include hot-dip galvanizing, electroplating, and painting. These coatings provide a barrier between the alloy steel surface and the environment, preventing corrosion and extending the lifespan of the billets. In summary, the different surface treatments applied to alloy steel billets include shot blasting, pickling, heat treatment, and protective coatings. These treatments help to improve the surface quality, enhance mechanical properties, and protect the billets from corrosion, ultimately ensuring optimal performance in various applications.

- Q: Our caster is square billet! 150X500! That is, every time we open the head, there is slag inclusion. And pores! Yes, the first 3 meters! There's no more left behind! How did it happen, please?! We have a refinery and electromagnetic stirring! Give me a hand!

- In the production process of steel castings, the appearance of quality defects is unavoidable. It is essential to take reasonable measures to avoid the inclusion of slag in the cast steel. It is necessary to understand the reason why the porosity of the cast steel is caused by slag inclusion so that the quality of the cast steel can be improved.In order to solve the pinhole of slag phenomenon, the first thing to do is to understand the cause of steel casting porosity slag phenomenon, and take corresponding measures according to the original material,

- Q: What are the potential applications of steel billets in the transportation industry?

- Steel billets have a wide range of potential applications in the transportation industry. One of the main uses of steel billets in transportation is for the manufacturing of various parts and components for automobiles, such as engine blocks, chassis, suspension systems, and wheels. Steel billets provide the necessary strength and durability required for these critical components, ensuring the safety and reliability of vehicles. Additionally, steel billets are commonly utilized in the production of railway tracks, ensuring the stability and longevity of the rail infrastructure. The high strength and resistance to wear and tear make steel billets an ideal choice for this application, as they can withstand heavy loads and extreme weather conditions. Furthermore, steel billets are used in the construction of ships and boats. The marine industry relies on the strength and corrosion resistance of steel billets to build hulls, decks, and various structural components. Steel billets also play a crucial role in the construction of bridges, providing the necessary strength and structural integrity to support heavy traffic loads. Moreover, steel billets are extensively used in the manufacturing of aircraft parts and components. The aviation industry demands materials with exceptional strength-to-weight ratio, and steel billets meet this requirement. They are utilized in the production of landing gear, engine mounts, and other critical aircraft structures. Overall, the potential applications of steel billets in the transportation industry are vast and varied. Their strength, durability, and resistance to wear and tear make them an essential material for the production of parts and components in automobiles, railway tracks, ships, boats, aircraft, and bridges. Steel billets contribute to the safety, reliability, and efficiency of transportation systems, making them indispensable in this industry.

Send your message to us

Prime Square Steel Billet 150x150mm 165x165mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 19684 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords