Mild Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Chinese Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mild Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Chinese Supplier

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel in Hot Sale

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel Prime Steel Billet

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

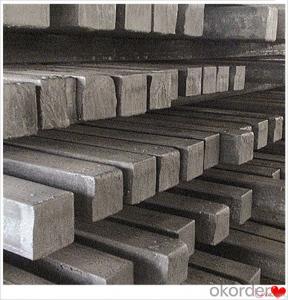

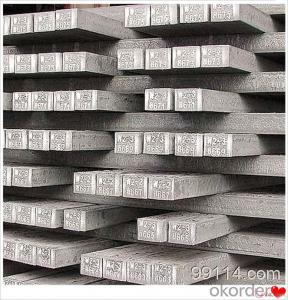

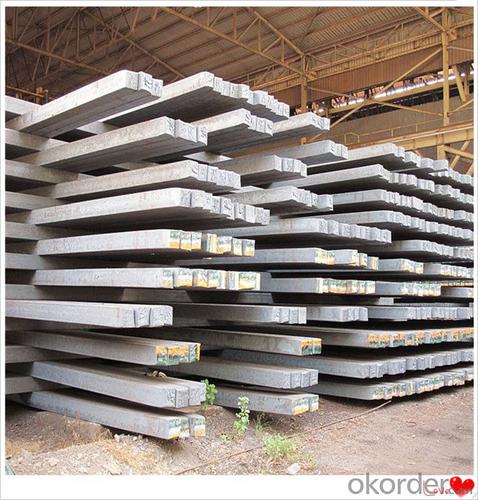

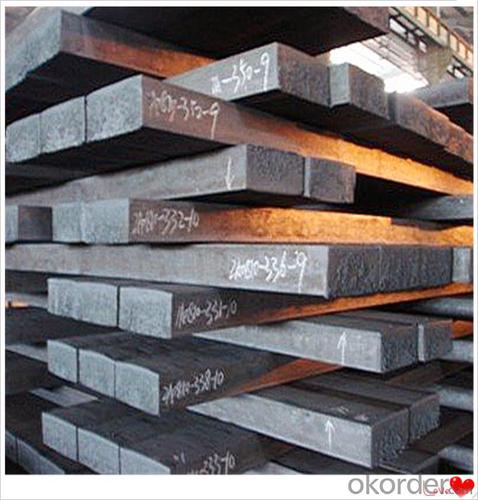

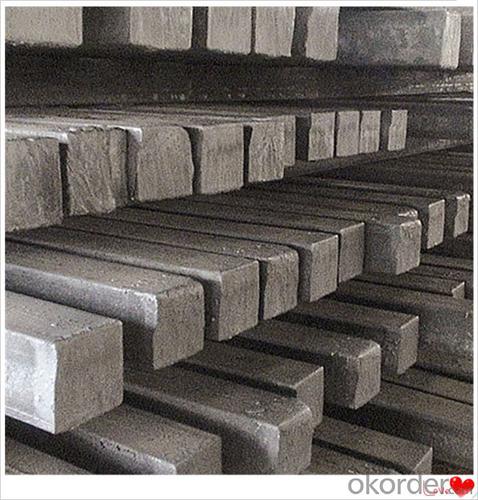

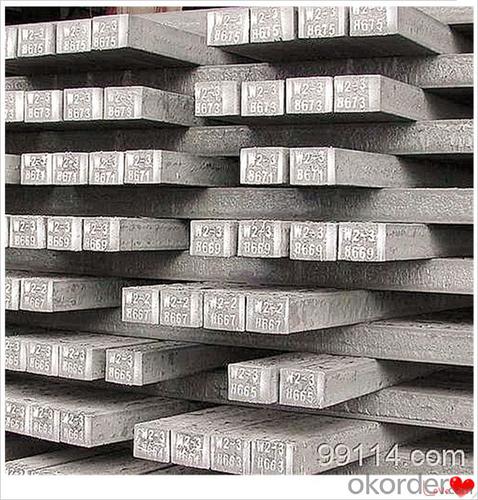

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: How are steel billets used in the manufacturing of furniture?

- Furniture manufacturing commonly utilizes steel billets as the primary material for various components. These billets undergo heating and molding processes to take on different shapes, ultimately forming the structural framework of chairs, tables, and bed frames. The use of steel in furniture production is preferred due to its malleability and strength, which contribute to the durability and stability of the final product. Furthermore, steel billets can be easily welded and joined together, allowing for the creation of intricate designs and structures. In summary, steel billets play a crucial role in the manufacturing of high-quality and long-lasting furniture pieces, providing the necessary strength and versatility.

- Q: What are the different types of welding processes used for joining steel billets?

- There are several different types of welding processes that can be used for joining steel billets. Each method has its own unique characteristics and advantages, depending on the specific requirements of the project. Here are some of the most commonly used welding processes for joining steel billets: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW uses a consumable electrode coated in flux to create an arc between the electrode and the base material. This process is versatile and can be used for both thick and thin steel billets, making it widely used in various industries. 2. Gas Metal Arc Welding (GMAW): Commonly known as MIG welding, GMAW uses a continuous wire electrode and a shielding gas to protect the weld from atmospheric contamination. This process offers high productivity and is suitable for welding steel billets of various thicknesses. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a continuously fed tubular electrode filled with flux. This process is ideal for welding thicker steel billets and is often used in heavy fabrication applications. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, GTAW uses a non-consumable tungsten electrode and a separate filler metal. This process produces high-quality welds and is commonly used for joining steel billets in applications that require precision and aesthetic appeal. 5. Submerged Arc Welding (SAW): SAW involves the use of a continuously fed electrode and a granular flux that covers the weld area. The process is particularly suitable for welding thick steel billets and is often used in the construction of pressure vessels and heavy machinery. 6. Laser Beam Welding (LBW): LBW utilizes a laser beam to generate heat and join the steel billets. This process offers high precision and speed, making it suitable for a wide range of applications, including automotive and aerospace industries. 7. Electron Beam Welding (EBW): EBW uses a high-velocity electron beam to melt and join the steel billets. This process provides deep penetration and precise control, making it ideal for critical applications that require high-quality welds. It is important to consider the specific requirements, thickness, and material properties of the steel billets when selecting the appropriate welding process. Consulting with a welding expert can help determine the most suitable method for a given project.

- Q: How are steel billets used in the manufacturing of renewable energy equipment?

- Steel billets are used in the manufacturing of renewable energy equipment as a primary raw material. These billets are shaped and processed to create various components such as wind turbine towers, solar panel frames, and hydroelectric power structures. The strong and durable nature of steel allows for the construction of robust and long-lasting renewable energy equipment, ensuring their reliability and performance in harnessing sustainable energy sources.

- Q: How are steel billets used in the production of oil and gas components?

- Steel billets are used in the production of oil and gas components as they serve as the primary raw material for manufacturing various parts and equipment such as pipes, valves, flanges, and fittings. These billets are heated and shaped through processes like rolling, forging, or extrusion to achieve the desired dimensions and properties required for the specific component. The strength, durability, and corrosion resistance of steel make it an ideal choice for oil and gas applications, ensuring the reliability and integrity of the produced components.

- Q: What is the role of steel billets in the production of automotive components?

- The role of steel billets in the production of automotive components is to serve as the raw material for forging or casting processes. These billets are heated and shaped into various automotive parts, such as engine components, chassis parts, and suspension systems. Steel billets provide the necessary strength and durability required for these components to withstand the demanding conditions and stresses encountered in automotive applications.

- Q: What are the main factors that influence the strength of steel billets?

- The main factors that influence the strength of steel billets are the chemical composition, heat treatment, and microstructure of the steel. The chemical composition of steel billets plays a significant role in determining their strength. The presence of alloying elements such as carbon, manganese, silicon, and chromium can enhance the strength of steel by forming solid solutions or precipitates that increase the hardness and tensile strength of the material. Additionally, controlling the impurity levels and ensuring the desired balance of alloying elements is crucial in achieving the desired strength properties. Heat treatment is another crucial factor that influences the strength of steel billets. The heat treatment process involves heating the steel to a specific temperature, followed by cooling at a controlled rate. This process can significantly affect the microstructure of the steel, which in turn impacts its strength. For instance, quenching and tempering can result in the formation of a desired microstructure, such as martensite or bainite, which enhances the strength and toughness of the steel. The microstructure of steel billets is a key factor in determining their strength. The arrangement of the crystal grains and the presence of various phases within the steel can greatly influence its mechanical properties. Fine-grained structures generally exhibit higher strength due to a greater number of grain boundaries, which inhibit dislocation movement and enhance strength. Additionally, the presence of specific microstructural features, such as precipitates or second-phase particles, can also contribute to the strength of steel billets. Furthermore, factors such as the manufacturing process, cooling rate during solidification, and mechanical working (such as rolling or extrusion) can affect the strength of steel billets. These factors influence the grain size, grain boundary density, and defect concentration, all of which impact the mechanical properties of the steel. In summary, the strength of steel billets is influenced by the chemical composition, heat treatment, and microstructure of the steel. These factors can be carefully controlled and optimized to achieve the desired strength properties for various applications.

- Q: Can steel billets be used in the production of jewelry?

- Due to its composition and properties, steel billets are usually not utilized in jewelry production. Steel, which is primarily made up of iron and carbon and contains additional elements like manganese, chromium, and nickel, possesses strength and durability that make it well-suited for various industrial applications, but not for crafting jewelry. In contrast, jewelry is typically crafted from precious metals like gold, silver, and platinum, which possess unique characteristics that make them suitable for adornment. These metals are easily shaped and molded into intricate designs due to their malleability. Moreover, they have a lustrous appearance and are resistant to tarnishing or corrosion. On the other hand, steel is much harder and less malleable compared to precious metals. It cannot be easily manipulated into the delicate and intricate shapes required for jewelry making. Additionally, steel has a dull gray color that does not offer the desired aesthetic appeal in jewelry. While it is technically possible to create jewelry using steel billets, it is not a common practice due to the aforementioned reasons. Steel is primarily utilized in industries where its high strength and durability are necessary, such as construction, automotive, and machinery manufacturing.

- Q: How are steel billets used in the production of railway tracks?

- Steel billets are the raw materials used in the production of railway tracks. They are heated, shaped, and rolled to form long, flat bars known as rails. These rails are then laid on the trackbed, forming the foundation for the tracks on which trains run.

- Q: What is the average lead time for ordering steel billets?

- The lead time for ordering steel billets can vary depending on several factors, including the supplier, quantity needed, production capacity, and current market conditions. Typically, the lead time can range from a few weeks to a couple of months. If the supplier has readily available stock or a short production cycle, the lead time may be shorter, usually around two to four weeks. However, if the supplier needs to produce the steel billets specifically for the order, it may take longer. In such cases, the lead time can extend to six to eight weeks or even longer, particularly if there are any production process delays. Considering the quantity required is also crucial. Smaller orders may have shorter lead times compared to larger quantities, as they can be accommodated within the supplier's existing production schedule or available stock. Furthermore, market conditions play a significant role. When there is high demand or disruptions in the supply chain, lead times may increase due to heightened competition for resources and longer production cycles. To obtain an accurate estimate of the average lead time for ordering steel billets, it is advisable to contact multiple suppliers and discuss your specific requirements with them. They can provide more precise information based on their production capabilities and the current market conditions.

- Q: What are the potential applications of steel billets in the transportation sector?

- Steel billets have several potential applications in the transportation sector, including the production of various components such as engine parts, chassis, and body frames. They offer excellent strength-to-weight ratio, durability, and resistance to corrosion, making them ideal for manufacturing vehicles that can withstand harsh conditions. Additionally, steel billets can be easily formed into different shapes, allowing for the creation of complex and lightweight designs. Overall, their versatility and reliability make steel billets a valuable material in the transportation industry.

Send your message to us

Mild Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Chinese Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords