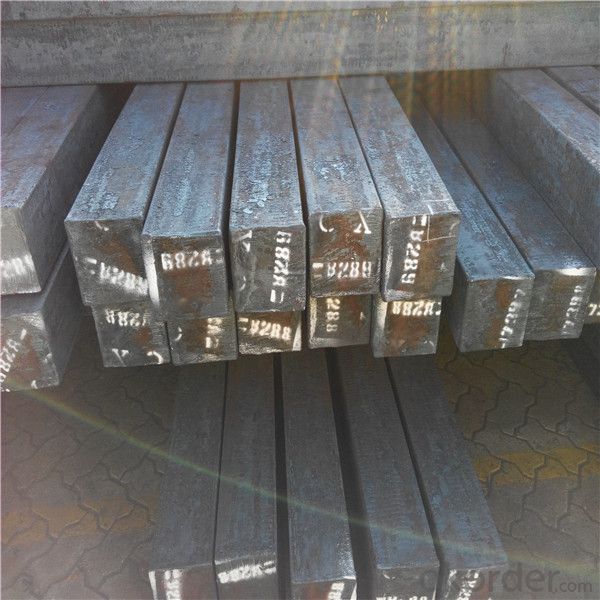

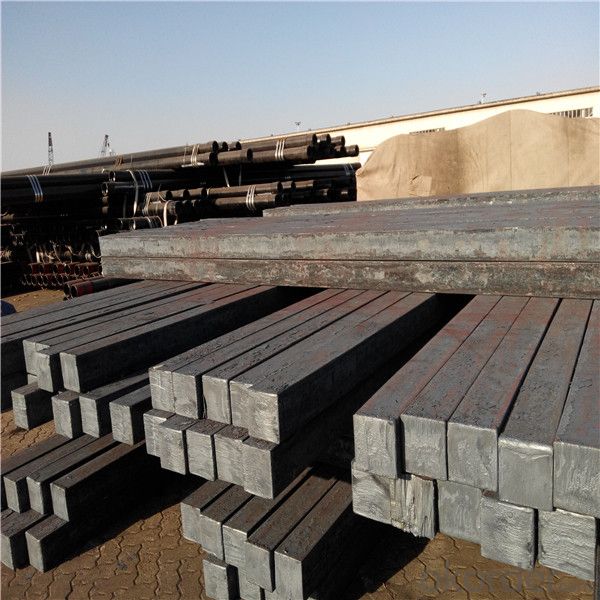

China steel billets good price Q195 Q215 Q235 Q275

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17142 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still require

a series of shaping and molding procedures such as hot and cold working, milling and cutting before they

are sold in hardware stores, or used for different applications. The unformed billets, however, can be used

in striking currency such as coins and as reserves, similar to gold bars.

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets

have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also

known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Other Specifications

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How are steel billets used in the manufacturing of slabs?

- Steel billets are an essential raw material used in the manufacturing of slabs. Slabs are large, flat pieces of steel that are used as a primary input in various industries, such as construction, automotive, and manufacturing. To produce slabs, the first step involves obtaining steel billets. These billets are semi-finished steel products that are typically obtained through the continuous casting process or by hot-rolling ingots. They are solid, rectangular or square-shaped blocks of steel with a cross-sectional area that can vary depending on the desired size and thickness of the slabs. Once the steel billets are obtained, they are heated to a high temperature to make them more malleable and easier to shape. This process, known as hot rolling, involves passing the billets through a series of rolling mills to progressively reduce their thickness and increase their length. The rolling mills apply intense pressure to the billets, causing them to elongate and acquire the desired dimensions. During the hot rolling process, the steel billets are often subjected to various manipulations, such as reheating and cooling, to ensure proper shaping and metallurgical properties. The billets may also go through additional processes, such as descaling (removing the oxide layer) and surface treatment, to enhance their quality and finish. Once the hot rolling process is completed, the steel billets are transformed into slabs. These slabs are then further processed to meet specific requirements. For instance, they may undergo additional rolling or reheating processes to achieve the desired thickness, dimensions, and surface finish. The slabs can also be cut into smaller pieces or further processed into different steel products, such as plates, sheets, or coils, depending on the intended use. In summary, steel billets play a crucial role in the manufacturing of slabs. They serve as the starting point for the production process, undergoing hot rolling and other treatments to transform them into the desired shape, size, and quality. The resulting slabs are then used as a primary input in various industries, contributing to the production of a wide range of steel products.

- Q: What are the different surface treatments for improved surface lubrication in steel billets?

- There are several surface treatments that can be applied to steel billets to improve surface lubrication. These treatments aim to reduce friction and wear during various manufacturing processes, such as rolling or extrusion. Some of the common surface treatments for improved surface lubrication in steel billets include: 1. Phosphating: This treatment involves the application of a phosphate coating to the steel surface. Phosphating creates a thin layer of a phosphate compound, which acts as a lubricant and reduces friction between the billet and the machinery during processing. 2. Nitriding: Nitriding is a process that introduces nitrogen into the steel surface, forming a nitride layer. This layer improves the surface hardness and wear resistance of the billet, enhancing its lubrication properties and reducing friction. 3. Electroplating: Electroplating involves depositing a layer of metal, such as zinc or nickel, onto the steel billet's surface. This coating not only improves lubrication but also provides corrosion protection, extending the lifespan of the billet. 4. Surface coating: Various types of coatings, such as Teflon or other polymer-based coatings, can be applied to steel billets. These coatings create a low-friction surface, preventing sticking or galling during processing. 5. Shot peening: Shot peening is a mechanical surface treatment that involves bombarding the steel surface with small, high-velocity metal shots. This process induces compressive stress in the surface layer, increasing its resistance to wear and reducing friction. 6. Case hardening: Case hardening is a heat treatment process that involves the diffusion of carbon or other alloying elements into the steel surface. This treatment forms a hardened outer layer, which enhances lubrication properties and reduces friction during processing. Overall, these surface treatments for improved surface lubrication in steel billets offer various advantages, such as reduced wear, improved efficiency, and extended tool life. The choice of treatment depends on the specific application requirements and the desired properties of the billet.

- Q: What are the main uses of steel billets in the automotive industry?

- Various applications in the automotive industry make steel billets widely used. One of their primary uses involves the production of forged components, such as crankshafts, connecting rods, and camshafts. These components demand high strength and durability, qualities that steel billets possess and meet these requirements. Gears, axles, and transmission shafts also rely on steel billets for their manufacturing. These parts must withstand heavy loads and ensure smooth and efficient power transmission within the vehicle. Steel billets possess excellent mechanical properties, including high tensile strength and toughness, which make them the ideal choice for such applications. Furthermore, suspension components like control arms, steering knuckles, and suspension links depend on steel billets. These components play a crucial role in maintaining vehicle stability, control, and comfort. Steel billets are preferred for these parts due to their exceptional strength, stiffness, and impact resistance. Moreover, body and chassis components, such as pillars, beams, frames, and reinforcements, benefit from the use of steel billets. These components provide structural integrity and crash protection to the vehicle. Steel billets offer a superior strength-to-weight ratio, corrosion resistance, and formability, making them a popular choice for these safety-critical components. In conclusion, steel billets find applications in the automotive industry for forged components, gears and transmission parts, suspension components, and body and chassis components. Their exceptional mechanical properties are indispensable for building durable, reliable, and safe vehicles.

- Q: What are the different shapes and forms of steel billets?

- Depending on their intended use and manufacturing process, steel billets are available in a variety of shapes and forms. Casting is the typical process used to achieve the most common shapes, which include square, rectangular, round, and hexagonal. Square billets are widely used and are often rolled into long products such as bars, rods, and wire. Rectangular billets, with longer sides compared to their width, are also rolled into long products but are typically used for applications that require a larger cross-sectional area. Round billets, as their name suggests, are cylindrical and primarily used for producing seamless tubes, pipes, and other tubular products. The round shape is preferred in these applications as it allows for a more uniform distribution of stresses during manufacturing. Hexagonal billets, with their six sides, are commonly used for forging and machining. Their unique shape provides greater strength and stability, making them suitable for producing high-quality components like bolts, nuts, and other fasteners. In addition to these common shapes, steel billets can also be customized to meet specific requirements in terms of shape and size. Specialized molds or further processing techniques like extrusion or hot rolling can be used to achieve these custom shapes. Overall, the various shapes and forms of steel billets enable the production of a wide range of steel products, each tailored to its specific application and manufacturing process.

- Q: How are steel billets used in the manufacturing of machinery?

- Steel billets are used in the manufacturing of machinery as a primary raw material. They are heated and shaped into various components, such as gears, shafts, and structural frames, which are then assembled to create the machinery. The high strength and durability of steel billets make them ideal for withstanding heavy loads and harsh working conditions, ensuring the reliability and longevity of the machinery.

- Q: How are steel billets used in the manufacturing of pipes?

- Steel billets are an essential component in the manufacturing of pipes. These billets, which are semi-finished products made of steel, serve as the raw material for pipe production. The process begins with the selection of high-quality steel and melting it in a furnace to create a molten steel alloy. Once the steel is molten, it is poured into molds to form billets of specific sizes and shapes. The billets are then allowed to cool and solidify. This solidification process ensures that the steel attains its desired structural properties, such as strength and durability. After the steel billets have cooled, they undergo further processing to transform them into seamless or welded pipes. For the production of seamless pipes, the billets are heated and pierced to create a hollow tube-like structure. The pierced billets are then elongated and stretched to obtain the desired pipe diameter and thickness. This process, known as the hot-rolling technique, results in seamless pipes with consistent dimensions and enhanced mechanical properties. Welded pipes, on the other hand, are manufactured using different methods. One common method is the electric resistance welding (ERW) process, where the billets are first heated and then passed through a series of rollers to shape them into a cylindrical form. The edges of the billets are then fused together using an electric current, creating a continuous weld. Other welding techniques, such as submerged arc welding (SAW) and high-frequency induction welding (HFIW), can also be used to manufacture welded pipes from steel billets. In both seamless and welded pipe manufacturing, the quality of the steel billets is crucial for ensuring the integrity and performance of the final product. The selection of appropriate steel grades and the adherence to strict manufacturing standards are vital to produce pipes that can withstand high pressure, extreme temperatures, and corrosive environments. In conclusion, steel billets play a vital role in the manufacturing of pipes. They serve as the starting material from which pipes are formed, whether through the hot-rolling technique for seamless pipes or various welding methods for welded pipes. By utilizing high-quality steel billets and employing precise manufacturing processes, pipes can be produced with the necessary strength, durability, and dimensional accuracy to meet a wide range of industrial and commercial applications.

- Q: How are steel billets used in the production of transmission components?

- In the production of transmission components, steel billets are indispensable raw materials. These semi-finished products are typically obtained through the casting process and have a rectangular or square shape with a larger cross-sectional area compared to the final product. To shape the steel billets into the desired forms, a series of processes such as forging, rolling, or extrusion are employed. Each of these processes aims to transform the steel billets into specific shapes and sizes required for transmission components like gears, shafts, bearings, and housings. Forging is a widely used method for shaping steel billets. It involves heating the billet and using mechanical force to deform it into the desired shape, thereby enhancing the strength and durability of the transmission components. Rolling, on the other hand, gradually reduces the cross-sectional area of the steel billets by passing them through a series of rollers. This process helps achieve the desired shape and dimensions of the components. In certain cases, extrusion is employed to produce complex shapes. This process involves forcing the steel billets through a die to obtain the desired form, allowing for the production of intricate transmission components like splined shafts or valves. After shaping the steel billets into the required forms, further machining processes such as cutting, drilling, and grinding are carried out to achieve the final specifications. These components are then heat-treated and coated to enhance their strength, durability, and resistance to corrosion. In summary, steel billets play a crucial role in the production of transmission components as they provide a versatile and reliable raw material that can be shaped into various forms. They ensure that the transmission components possess the necessary strength, durability, and precision required for efficient and reliable operation in vehicles and machinery.

- Q: Are steel billets susceptible to corrosion?

- Steel billets can be affected by corrosion. Steel, which is mostly made up of iron and carbon, is prone to corrosion because of the presence of iron. When exposed to moisture and oxygen, a chemical reaction occurs on the surface of the steel, resulting in the formation of rust, also known as iron oxide. This corrosion weakens the structure of the steel and can eventually cause it to fail. To prevent corrosion, protective layers are often applied or anti-corrosion agents are used on steel billets. Common methods include galvanizing, where a layer of zinc is added, or coating the steel with paint or epoxy. Additionally, storing steel billets in dry environments and ensuring proper ventilation can help reduce the risk of corrosion. It's worth noting that the susceptibility to corrosion can also depend on the specific composition and grade of the steel used in the billets. Certain types of stainless steel, for example, contain additional elements such as chromium and nickel, which offer improved resistance to corrosion. However, even stainless steel can corrode under certain conditions, although at a slower rate compared to regular carbon steel. Regular inspection, maintenance, and appropriate corrosion prevention measures are essential in ensuring the long-lasting durability of steel billets.

- Q: What are the challenges faced in the distribution and supply chain of steel billets?

- The distribution and supply chain of steel billets encounter several challenges. Firstly, transportation poses a major obstacle due to the heavy and bulky nature of steel billets. Specialized equipment and infrastructure are necessary, which can result in higher logistics costs and difficulties in finding suitable transport options, particularly for international shipments. Secondly, the storage and inventory management of steel billets present challenges. Proper storage facilities are required to prevent corrosion and damage. Moreover, managing inventory levels and ensuring timely deliveries become complex as steel billets are sourced from multiple suppliers and delivered to various locations. Thirdly, maintaining quality control is a significant challenge. Consistent quality throughout the supply chain demands strict adherence to quality standards and effective quality control measures. Regular inspections, testing, and certification processes are necessary to ensure the integrity and suitability of the steel billets. Another challenge stems from fluctuating demand and market conditions. The steel industry is highly cyclical, with demand and prices influenced by economic fluctuations and global market trends. Consequently, forecasting demand, managing production capacity, and optimizing inventory levels to meet customer requirements while minimizing costs become difficult. Furthermore, global trade regulations and customs procedures create challenges. Compliance with various import and export regulations, including trade restrictions and tariffs, can affect the flow of steel billets across different countries, leading to delays and additional costs. Lastly, ensuring sustainable and responsible sourcing practices is increasingly important. Meeting environmental and social standards, such as responsible sourcing of raw materials and reducing carbon emissions, poses challenges for steel billet manufacturers and distributors. Implementing sustainable practices throughout the supply chain may involve additional costs and complexities. In conclusion, the distribution and supply chain of steel billets face challenges related to transportation, storage, quality control, demand fluctuations, trade regulations, and sustainable sourcing. Overcoming these challenges necessitates effective planning, strong partnerships, and the implementation of efficient processes to ensure a smooth and reliable supply of steel billets to customers.

- Q: How are steel billets used in the construction of bridges?

- Due to their exceptional strength and durability, steel billets play a crucial role in bridge construction. These cylindrical pieces of raw steel are heated and shaped into various structural components, such as beams, columns, and girders, which serve as the foundation of bridge structures. The initial step in utilizing steel billets for bridge construction involves heating them in a furnace to make them malleable. Once the desired temperature is reached, the billets are passed through a series of rollers to shape them into the required sections. This process, referred to as hot rolling, guarantees that the steel achieves the necessary strength and structural integrity. Following this, the shaped steel billets undergo further processing and fabrication to form different bridge components. For example, beams are created by cutting and welding steel billets together to form long, horizontal members that bear the weight of the bridge deck. These beams are designed to withstand heavy loads and provide stability to the entire structure. On the other hand, columns are vertical members that transfer the load from the bridge deck to the foundations. Steel billets are shaped and joined together to construct these load-bearing columns, ensuring they possess the required strength to endure compression forces. Girders also play a vital role in bridge construction, serving as horizontal supports that span across the width of the bridge. Steel billets are shaped into girders, which are then fabricated and connected to the bridge's piers or abutments. These girders provide the necessary strength to evenly distribute the weight of the bridge deck. Aside from their strength, steel billets offer several advantages in bridge construction. They possess a high resistance to corrosion, guaranteeing the durability and longevity of the bridge structure. Additionally, steel billets are highly versatile, allowing engineers to create various shapes and sizes, enabling the design of bridges that meet specific project requirements. Overall, steel billets are extensively utilized in bridge construction due to their strength, durability, and versatility. They form the foundation of bridge structures, providing the necessary support and stability to ensure the safe and efficient transportation of people and goods.

Send your message to us

China steel billets good price Q195 Q215 Q235 Q275

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17142 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords