Steel Billet from China Alibaba Q215 Q235 Q275

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17684 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets

have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also

known for their malleability and ductility, especially when exposed to varying temperatures during shaping and

molding.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support

foundation pile manufacturing.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Other Specifications

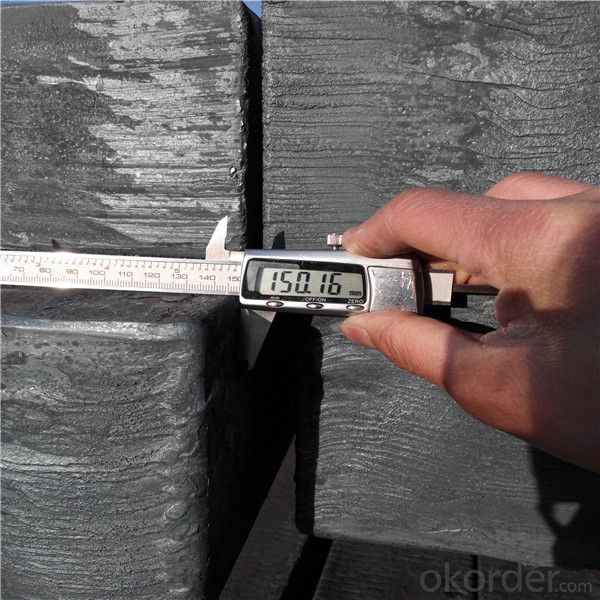

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What is the difference between continuous casting billet and cast billet?

- but with high-grade continuous casting line (full protection casting, electromagnetic stirring, liquid stopper control) compared both have a big difference in the crystal, oxidation, surface quality.

- Q: How are steel billets shaped into other forms?

- A process known as hot rolling is used to transform steel billets into different forms. This process involves feeding the steel billet through heated rollers, which compress and mold it into the desired shape. To begin, the steel billet is heated to a high temperature in a furnace. This heat treatment makes the steel more malleable and easier to shape. Once the billet has reached the desired temperature, it is then sent into a rolling mill. Within the rolling mill, the billet undergoes a series of passes through rollers that apply pressure and force to shape the steel. These rollers come in various shapes and sizes depending on the desired outcome. As the billet passes through the rollers, it gradually takes on the desired form, such as sheets, bars, or beams. The rolling process not only shapes the steel but also improves its mechanical properties. It refines the grain structure, enhances strength and toughness, and eliminates any internal defects. This makes the steel more suitable for a range of applications, including construction, automotive, and machinery. Following the hot rolling process, the steel often undergoes additional processing through cold rolling. This involves passing the steel through cold rollers to further refine its surface finish and dimensions. Additionally, secondary operations like cutting, bending, and welding may be carried out to further shape the steel into the desired end product. In conclusion, hot rolling plays a vital role in transforming steel billets into various forms. It enables the production of a wide range of steel products, each with its own unique shape, size, and mechanical properties. This helps meet the diverse needs of industries worldwide.

- Q: How are steel billets used in the production of marine components?

- Steel billets are used in the production of marine components as they serve as the raw material from which various marine parts are manufactured. These billets are heated, shaped, and machined to create components like ship hulls, propeller shafts, engine parts, and other structural elements. By using steel billets, marine manufacturers can ensure the strength, durability, and corrosion resistance required for reliable performance in the demanding marine environment.

- Q: Can steel billets be used for structural purposes?

- Structural purposes can indeed be served by steel billets. These particular steel products are considered semi-finished and are typically shaped through hot-rolling or forging techniques to create various structural components such as beams, columns, and more. Their utilization in construction and engineering projects is widespread due to their ability to provide strength, durability, and the capability to bear heavy loads. Before being incorporated into the construction process, these billets are often further processed and shaped according to specific design requirements. The construction industry heavily relies on steel billets for the construction of buildings, bridges, highways, and other infrastructure projects due to their exceptional mechanical properties and high strength-to-weight ratio. Moreover, their suitability for various structural applications is enhanced by their ease of welding.

- Q: What are the main safety precautions in handling steel billets?

- When handling steel billets, there are several important safety precautions that should be followed to minimize the risk of accidents and injuries. 1. Personal Protective Equipment (PPE): It is vital to wear appropriate PPE, such as steel-toed boots, protective gloves, safety glasses, and a hard hat. This gear provides essential protection against potential hazards such as falling objects, sharp edges, and splashes. 2. Lifting and Handling Techniques: Proper lifting techniques should be used to avoid strains and injuries. It is essential to bend the knees and lift with the legs, keeping the back straight. Using mechanical aids like cranes or forklifts can also help reduce the physical strain of lifting heavy steel billets. 3. Secure Storage and Stacking: Steel billets should be stored securely to prevent them from falling or rolling over. They should be stacked in a stable manner, ensuring that the bottom layer is strong enough to support the weight. Using racks, pallets, or other appropriate storage systems can help maintain stability. 4. Proper Machinery Operation: If machinery or equipment is used to transport or manipulate steel billets, it is crucial to follow the manufacturer's instructions and operate the machinery safely. This includes regular maintenance checks, ensuring that safety guards are in place, and using equipment within its specified capacity. 5. Hazard Communication: Clear signage and labels should be used to indicate the presence of steel billets or any potential hazards associated with their handling. Workers should be trained to recognize and understand these signs and be aware of the risks involved. 6. Fire Prevention: Steel billets can pose a fire hazard if they come into contact with flammable materials or are exposed to high temperatures. Therefore, it is important to keep the work area clean and free from combustible substances. Additionally, fire extinguishers should be readily available, and workers should be trained in their proper usage. 7. Training and Education: Proper training and education programs should be implemented to ensure that all workers are familiar with the potential hazards of handling steel billets and know how to mitigate them. This training should cover safety procedures, emergency response protocols, and the correct use of personal protective equipment. By following these safety precautions, the risk of accidents and injuries when handling steel billets can be significantly reduced, creating a safer working environment for all personnel involved.

- Q: What are the main factors affecting the wear resistance of steel billets?

- The wear resistance of steel billets can be influenced by several key factors. Firstly, the composition of the steel plays a crucial role. The presence of specific alloying elements, like chromium, manganese, and molybdenum, greatly enhances the steel's wear resistance. These elements form carbides and other compounds that create a durable and hard surface capable of withstanding abrasion. In addition, the microstructure of the steel is vital in determining its wear resistance. Fine-grained steels tend to have better wear resistance due to their smaller grain size, which provides a more uniform and dense structure, reducing the likelihood of cracks and wear. Heat treatment processes, such as quenching and tempering, can further refine the microstructure and enhance wear resistance. The surface finish also affects wear resistance. A smooth and well-polished surface reduces friction between the steel billet and its surroundings, minimizing wear. Various machining techniques, such as grinding and polishing, can be used to achieve the desired surface finish. Furthermore, the hardness of the steel billet is a significant factor in wear resistance. Hardness is commonly measured using the Rockwell or Brinell scales, and higher hardness values generally indicate improved wear resistance. Heat treatment, alloying, and the addition of hardening agents can all help increase the hardness of the steel billet. Lastly, environmental factors can impact wear resistance. The presence of corrosive substances, high temperatures, or abrasive particles in the working environment can accelerate wear and reduce the lifespan of the steel billet. Implementing appropriate coatings, like chromium plating or thermal spraying, can mitigate these environmental effects and enhance wear resistance.

- Q: What are the different types of steel billet rolling defects?

- Some of the different types of steel billet rolling defects include surface cracks, scale formation, edge cracks, internal cracks, surface defects (such as pits, scars, and scratches), shape defects (such as bowing, wavy edges, and center buckling), and size defects (such as undersized or oversized billets).

- Q: What is the role of steel billets in the manufacturing of hydraulic systems?

- The manufacturing of hydraulic systems heavily relies on steel billets, which have a crucial role to play. These billets serve as the raw material used for creating various components and structures within these systems. In order for hydraulic systems to function properly, it is imperative for their components to possess qualities such as strength, durability, and resistance to corrosion and pressure. Steel billets, due to their exceptional strength and toughness, are the perfect starting material for manufacturing hydraulic system components. Typically made from carbon steel, these billets offer excellent mechanical properties, including high tensile strength and hardness. These properties ensure that the components can endure the high pressures and forces encountered within hydraulic systems without deforming or failing. Furthermore, steel billets undergo several manufacturing processes such as forging, machining, and heat treatment in order to shape them into the desired components. These processes enable the creation of intricate designs and precise dimensions, guaranteeing a proper fit and functionality within the hydraulic system. Additionally, steel billets are renowned for their excellent resistance to corrosion, an essential quality in hydraulic systems due to the presence of fluids and potential exposure to moisture. Corrosion can lead to component failure, leaks, and a decrease in system performance. By utilizing steel billets, these issues can be prevented, ensuring the longevity and reliability of the hydraulic system. To sum up, steel billets are indispensable in the manufacturing of hydraulic systems as they provide the necessary strength, durability, and resistance to corrosion required for the components within these systems. Their versatility and ability to be shaped and processed make them an ideal material choice for creating reliable and efficient hydraulic systems.

- Q: How are steel billets used in the production of aerospace components?

- Steel billets play a crucial role in the aerospace industry by serving as the initial material for manufacturing aerospace components. These billets, which are semi-finished steel forms, are either hot-rolled or forged into specific shapes and sizes. Aerospace manufacturers commonly use steel billets to produce critical components like landing gear, engine parts, structural elements, and fasteners. These billets are chosen for their outstanding strength, durability, and resistance to high temperatures and corrosive environments, all of which are vital characteristics for aerospace applications. The production process of aerospace components using steel billets involves several steps. Initially, the billets are heated to a high temperature to make them malleable and easy to work with. Various forming techniques like forging, extrusion, or rolling then shape the billets into the desired forms. These processes guarantee precise shaping and dimensional accuracy, ensuring that the components meet the required specifications and tolerances. After the initial shaping, further processes such as heat treatment, machining, and surface finishing are applied to enhance the mechanical properties and surface quality of the aerospace components. Heat treatment methods like quenching and tempering strengthen the steel, improving its hardness, toughness, and resistance to wear and fatigue. Subsequently, machining processes are utilized to achieve the final shape, size, and surface finish of the components. Once the components are manufactured, they undergo rigorous quality control measures to ensure compliance with the strict standards and regulations of the aerospace industry. Thorough inspections, non-destructive testing, and material analysis are conducted to verify the integrity, performance, and safety of the components. In conclusion, steel billets are indispensable in the production of aerospace components, providing a reliable and robust starting material. The versatility and exceptional mechanical properties of steel make it the preferred choice in the aerospace industry, where reliability and safety are of utmost importance.

- Q: What is the cost of producing steel billets?

- The production cost of steel billets can vary depending on different factors, such as the quality of the raw materials used, the production process employed, and the market conditions. Typically, the cost of producing steel billets includes several components. Firstly, there is the cost of raw materials, which usually consist of iron ore, coal or coke, and other alloying elements. The prices of these materials can change due to global market dynamics and availability. Secondly, the cost of energy is a significant factor in steel billet production. This includes the cost of electricity and fuel needed for the manufacturing process, such as powering the blast furnaces or electric arc furnaces used to melt the raw materials. Thirdly, labor costs play a crucial role in the overall production cost. This includes wages for skilled and unskilled workers involved in operating the machinery, maintaining equipment, and overseeing the production process. In addition, there are indirect costs that need to be taken into account, such as expenses for machinery maintenance and repair, transportation costs for raw materials and finished products, and overhead costs related to administrative functions. It is important to note that external factors like government regulations, tariffs, and taxes can also influence the production cost of steel billets. Furthermore, market demand and competition can impact pricing strategies and ultimately affect production costs. Therefore, providing an exact cost figure for producing steel billets is challenging due to constant fluctuations. It is best to consult industry experts or steel manufacturers for the most accurate and up-to-date information on production costs.

Send your message to us

Steel Billet from China Alibaba Q215 Q235 Q275

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17684 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords