Steel Billets Q235 China Q235 Q275 Q345 Hot selling Billet Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

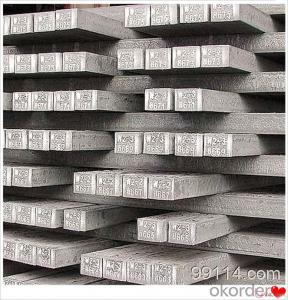

Steel Billets Q235 China Q235 Q275 Q345 Hot selling Billet Steel

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How are steel billets inspected for surface defects?

- Steel billets are inspected for surface defects using various methods and techniques to ensure the quality and integrity of the material. One common method is visual inspection, where trained inspectors carefully examine the surface of the billets for any visible defects such as cracks, scratches, pits, or uneven surfaces. They use proper lighting and magnification tools to thoroughly inspect the entire surface area. Another method used is dye penetrant testing. In this technique, a liquid dye is applied to the surface of the billets, which is then allowed to seep into any cracks or defects. After a specified time, excess dye is removed, and a developer is applied. The developer draws out the dye from any defects, making them clearly visible and easy to identify. Magnetic particle inspection is another widely used method. In this process, the billets are magnetized, and iron particles are applied to the surface. Any surface defects disrupt the magnetic field, causing the iron particles to gather around the defect, making them clearly visible upon inspection. This technique is particularly effective for detecting defects such as surface cracks. Ultrasonic testing is also commonly employed for inspecting steel billets. High-frequency sound waves are transmitted through the material, and any surface defects or internal flaws cause reflections or echoes. These reflections are detected and analyzed, providing information about the size, location, and type of defect present. Additionally, eddy current testing can be used to inspect steel billets for surface defects. This method involves passing an alternating current through a probe that is placed near the surface of the billet. Any defects or variations in the material's conductivity cause changes in the eddy currents, which can be detected and analyzed to identify surface defects. Overall, steel billets undergo meticulous inspection using a combination of visual, dye penetrant, magnetic particle, ultrasonic, and eddy current testing methods to ensure that any surface defects are identified and addressed, guaranteeing the quality and reliability of the final product.

- Q: How are steel billets used in the production of automotive chassis?

- Steel billets are used in the production of automotive chassis as they serve as the raw material for creating the main structural components of the chassis. These billets are heated and then shaped through processes like rolling or casting to form the desired chassis parts. The strength and durability of steel make it an ideal choice for chassis construction, ensuring the safety and stability of the vehicle.

- Q: What are the main factors affecting the heat resistance of steel billets?

- There are several main factors that can affect the heat resistance of steel billets. Firstly, the chemical composition of the steel plays a crucial role. Elements such as carbon, chromium, and nickel can enhance the heat resistance of steel by forming stable oxide layers on the surface that act as a protective barrier against high temperatures. Additionally, the presence of alloying elements like molybdenum and vanadium can also improve the heat resistance of steel by increasing its hardenability and reducing grain growth during heat treatment. Another important factor is the microstructure of the steel. Fine-grained structures tend to have higher heat resistance due to their increased strength and reduced susceptibility to thermal fatigue. Heat treatment processes like quenching and tempering can also alter the microstructure and improve the heat resistance of steel billets. The rate of heating and cooling also affects the heat resistance of steel. Rapid heating or cooling can lead to thermal shock and result in the formation of cracks or distortion in the billets. It is essential to control the heating and cooling rates to minimize these detrimental effects and maintain the desired heat resistance. Furthermore, the presence of impurities or defects within the steel can significantly impact its heat resistance. Inclusions, such as sulfur, phosphorus, and non-metallic oxides, can act as stress concentrators and reduce the heat resistance of steel. Similarly, internal defects like voids, cracks, or segregation regions can promote crack initiation and propagation during thermal cycles, thereby reducing the overall heat resistance of the steel billets. Lastly, the mechanical properties of the steel, such as its tensile strength, hardness, and ductility, can influence its heat resistance. Higher strength and hardness can generally enhance the heat resistance, while excessive ductility may lead to deformation or failure under high-temperature conditions. In summary, the main factors affecting the heat resistance of steel billets include the chemical composition, microstructure, rate of heating and cooling, presence of impurities or defects, and the mechanical properties of the steel. Understanding and optimizing these factors can help in producing steel billets with improved heat resistance for various applications.

- Q: How are steel billets used in the manufacturing of shafts?

- Steel billets are used in the manufacturing of shafts as the starting material. The billets are heated and then shaped and machined into the desired shape and size of the shaft. This process ensures that the shafts are strong, durable, and able to withstand the required loads and stresses in various applications.

- Q: How do steel billets contribute to the strength of a structure?

- Steel billets contribute to the strength of a structure by providing a high-strength, durable material that can withstand heavy loads and stress. Due to their composition and manufacturing process, steel billets offer superior strength and structural integrity, making them ideal for use in construction projects. They can be shaped and formed into various structural components, such as beams, columns, and reinforcement bars, which enhance the overall stability and load-bearing capacity of a structure. Additionally, the uniformity and consistency of steel billets ensure that the strength of the structure remains consistent throughout, further enhancing its overall strength and reliability.

- Q: What are the main factors that affect the international trade of steel billets?

- The international trade of steel billets is affected by various factors. These factors include the state of the global economy, government policies and regulations, currency exchange rates, technological advancements, environmental and sustainability considerations, and political stability and geopolitical factors. The global economy plays a vital role in determining the demand and supply of steel billets. Economic growth and stability in major importing and exporting countries impact the overall demand for steel products. A strong economy leads to increased construction and infrastructure projects, boosting the demand for steel billets. Government policies and regulations significantly impact the international trade of steel billets. Trade policies, import/export regulations, and tariffs imposed by governments can directly affect the competitiveness and cost of steel billets in the international market. Currency exchange rates influence the competitiveness of steel billets in international markets. Fluctuations in exchange rates can affect the demand and prices of steel billets. Technological advancements in steel production and manufacturing processes affect the international trade of steel billets. Improvements in production efficiency and the development of new steel grades can give certain countries a competitive advantage. Increasingly, environmental regulations and sustainability concerns are becoming important factors in international trade. Countries with stricter environmental regulations may require steel billet exporters to meet certain standards or obtain certifications, affecting their competitiveness. The demand for sustainable and low-carbon steel products also influences the trade of steel billets. Political stability and geopolitical factors can impact the international trade of steel billets. Political instability, conflicts, or trade disputes can disrupt supply chains and create uncertainties in the international trade of steel billets. In conclusion, the international trade of steel billets is influenced by economic, regulatory, technological, environmental, and geopolitical factors. Stakeholders in the steel industry need to understand and monitor these factors to make informed decisions in the global market.

- Q: How do steel billets contribute to the overall recyclability of a structure?

- Steel billets contribute to the overall recyclability of a structure because they can be easily melted down and reused in the production of new steel products. This reduces the need for raw materials and energy consumption, making the structure more environmentally sustainable. Additionally, the recycling process for steel billets is cost-effective, making it a viable option for manufacturers and builders.

- Q: What are the potential applications of steel billets in the chemical industry?

- Due to their unique properties and versatility, steel billets have numerous potential applications in the chemical industry. One primary use of steel billets in the chemical industry involves their utilization in the production of various types of equipment and machinery. Steel billets can be shaped and forged into different forms, such as pipes, tanks, valves, and fittings, which are crucial for the handling and storage of chemicals. These components need to withstand harsh conditions, including high temperatures, pressures, and corrosive environments, thereby making steel billets an ideal material choice. Additionally, steel billets can be employed in the construction of chemical plants and facilities. They provide exceptional structural support, ensuring the stability and integrity of the buildings. Steel billets are often used in fabricating beams, columns, and other load-bearing elements, providing strength and durability to withstand the chemical processes occurring within the plant. Another potential application of steel billets in the chemical industry pertains to the manufacturing of reaction vessels and reactors. These vessels are utilized for chemical reactions, such as synthesis, distillation, and purification processes. Steel billets can be machined and formed into the desired shape, allowing for the creation of robust and reliable vessels that can handle the high pressures and temperatures often required in chemical reactions. Furthermore, steel billets can be utilized in the production of catalysts used in various chemical processes. Catalysts are substances that expedite chemical reactions without being consumed in the process. Steel billets can serve as a base material for catalysts, providing a stable and durable support structure for the active catalytic components. Moreover, steel billets can be employed in the construction of storage tanks and containers for the transportation and storage of chemicals. Steel billets offer exceptional resistance to corrosion and can be easily welded and fabricated into large containers, ensuring the safe and secure storage of hazardous chemicals. In summary, steel billets possess vast potential applications in the chemical industry. Their strength, durability, and resistance to corrosion make them indispensable materials for various chemical processes and operations, encompassing equipment fabrication, construction projects, catalyst manufacturing, and storage solutions.

- Q: What are the common challenges in steel billet production?

- Some common challenges in steel billet production include ensuring consistent quality and composition, maintaining precise dimensions and tolerances, managing temperature control during the casting process, preventing defects and surface imperfections, and optimizing production efficiency and yield. Additionally, factors such as raw material quality, equipment maintenance, and skilled workforce are also critical in overcoming these challenges.

- Q: How are steel billets used in the production of pipes?

- Pipes rely heavily on steel billets as a vital raw material. To commence the manufacturing process, the billets undergo multiple transformations. To begin with, the steel billets are subjected to high temperatures, rendering them pliable. This procedure, known as hot rolling, enables the billets to be molded into lengthy cylindrical shapes. The heating process not only enhances the steel's internal structure but also eliminates any impurities. Once the billets have been heated, they are passed through a series of rolling mills. These mills gradually reduce the size of the billet, shaping it into a round bar called a "bloom." Subsequently, the bloom is further processed by traversing a piercing mill, which forms a hollow cavity in the center. Following the piercing process, the bloom is elongated and molded into a pipe through continuous rolling. The elongation is achieved by guiding the bloom through a sequence of sizing mills, gradually stretching and shaping it to the desired pipe dimensions. This continuous rolling process ensures uniform thickness and shape throughout the pipe's length. Moreover, steel billets can also be employed in the production of seamless pipes. In this scenario, the billets are heated and pierced in a manner similar to the aforementioned process. However, instead of elongation through rolling, the pierced billet is subjected to further processing known as extrusion, where it is elongated and reduced in diameter. This results in a seamless pipe devoid of welded joints, a preference in industries such as oil and gas. In summary, steel billets play an indispensable role in pipe manufacturing. Through processes involving heating, rolling, and shaping, the billets are transformed into pipes of various sizes and types. These pipes find applications in diverse industries, including construction, infrastructure, and energy, facilitating the transportation of fluids and gases.

Send your message to us

Steel Billets Q235 China Q235 Q275 Q345 Hot selling Billet Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords