Steel Billets Q235 Q235 Q275 Q345 for Fire Door Billet Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

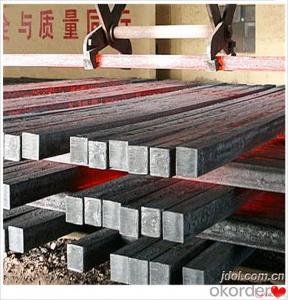

Steel Billets Q235 Q235 Q275 Q345 for Fire Door Billet Steel

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

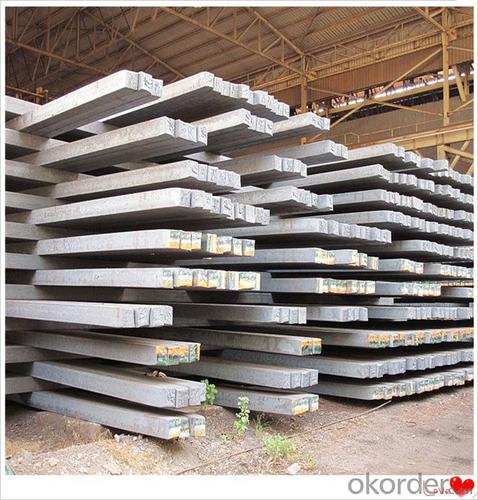

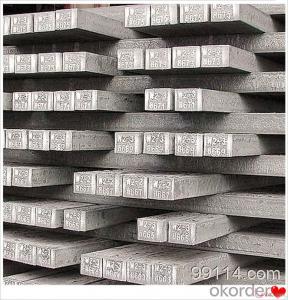

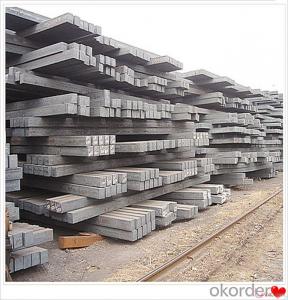

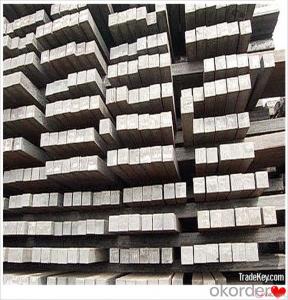

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: How are steel billets used in the manufacturing of automotive engine components?

- Steel billets are used in the manufacturing of automotive engine components as they serve as the raw material from which various engine parts are forged or machined. These billets are heated and shaped into different forms such as crankshafts, connecting rods, camshafts, and valves, which are integral to the functioning of an engine. By using steel billets, manufacturers can ensure the strength, durability, and reliability of these components, resulting in high-performance engines.

- Q: How are steel billets used in the manufacturing of food processing machinery?

- Steel billets are used in the manufacturing of food processing machinery as they provide the raw material for shaping and forming various components of the machinery, such as gears, shafts, and frames. The high strength and durability of steel billets ensure that the machinery can withstand the rigorous demands of food processing operations and maintain its functionality and longevity.

- Q: How are steel billets used in the production of automotive exhaust systems?

- Automotive exhaust systems rely heavily on steel billets as a vital element. These solid blocks of steel serve as the primary material for manufacturing various parts and components of the exhaust system. To begin the process, the steel billets are heated in a furnace to a specific temperature, which softens the steel and makes it malleable. Once heated, the billets are then molded and shaped into different components of the exhaust system, such as pipes, mufflers, and catalytic converters. The shaping process can be accomplished through hot rolling, cold rolling, or extrusion, depending on the desired shape and properties of the component. Following the shaping process, further treatment is carried out to enhance the strength and durability of the steel billets. This treatment may involve heat processes like quenching and tempering, which improve the steel's hardness, toughness, and resistance to corrosion. These treatments ensure that the exhaust system components can endure the harsh conditions they will encounter, including high temperatures and corrosive gases. Once the steel billets have been shaped and treated, they are assembled and welded together to form the final exhaust system. This involves joining the various components, such as pipes and mufflers, using welding techniques like arc welding or laser welding. These welding processes guarantee secure connections between the components, preventing any leaks or failures in the exhaust system. In summary, steel billets are of utmost importance in the production of automotive exhaust systems as they provide the necessary raw material for shaping and forming the various components. Their exceptional strength, durability, and resistance to high temperatures and corrosion make them an ideal choice for manufacturing exhaust systems capable of withstanding the demanding conditions associated with automotive use.

- Q: the ear has burrs, is it the billet problem or the rolling mill problem, will it be caused by the blowhole of the billet?

- Do not worry, you can go to the hospital to check

- Q: What are the potential applications of steel billets in the automotive industry?

- Due to their exceptional strength and durability, steel billets offer a wide range of potential applications in the automotive industry. One notable use is in the manufacturing of automotive components such as engine blocks, crankshafts, and transmission parts. These components necessitate a material that can endure high temperatures, heavy loads, and repetitive stress, which steel billets can provide. Another significant application is in the production of chassis and body panels. Steel billets are frequently employed to construct the structural framework of a vehicle, ensuring safety and stability by delivering the necessary strength and rigidity. Additionally, steel billets can be shaped and sized in various ways, permitting the customization of chassis components to meet the specific requirements of different vehicle models. Steel billets are also utilized in the production of suspension systems and steering mechanisms. These parts require a material capable of absorbing vibrations, damping shocks, and providing precise control. Steel billets possess these properties, making them an ideal choice for these essential automotive components. Furthermore, steel billets find applications in the production of exhaust systems due to their ability to withstand high temperatures and corrosive environments. The resistance of steel to rust and corrosion guarantees the longevity of the exhaust system, contributing to the overall performance and efficiency of the vehicle. In conclusion, the potential applications of steel billets in the automotive industry are extensive. From engine components to chassis parts, suspension systems to exhaust systems, steel billets offer the required strength, durability, and versatility to meet the demanding needs of the automotive sector.

- Q: What is the average price of steel billets?

- The average price of steel billets can vary depending on various factors such as the current market conditions, supply and demand dynamics, and the specific grade and quality of the steel billets. It is important to note that steel billet prices are influenced by global economic factors, including raw material costs, energy prices, and trade policies, which can lead to fluctuations in the average price. To get an accurate understanding of the average price of steel billets, it is recommended to refer to industry reports, trade publications, and market analysis platforms that provide up-to-date information on steel prices. Additionally, consulting with steel suppliers and manufacturers or engaging in negotiations with multiple sources can help determine the prevailing average price in a specific region or market.

- Q: How are steel billets used in the production of automotive steering systems?

- Steel billets are used in the production of automotive steering systems as they serve as the raw material for forging steering components such as the steering arm, tie rod ends, and steering knuckles. These billets are heated and shaped through forging processes to create strong and durable steering components that ensure the reliable performance and safety of the steering system in vehicles.

- Q: Is the reaction of carbon and carbon dioxide a redox reaction?

- According to the increase or decrease of the oxidation number, the redox reaction can be split into 2.5 reactions: the half reaction of increasing oxidation number is called the oxidation reaction, and the reaction of reducing the oxidation number is called the reduction reaction.In the reaction, the oxidizing substance, called the reducing agent, forms the oxidation product. The reducing reaction substance is called the oxidant, and the reduced product is produced. The oxidation product is oxidized but weaker than the oxidant; the reducing product is reductive but weaker than the reducing agent.Whether a chemical reaction belongs to an oxidation-reduction reaction depends on whether the reaction has an increase in the number of oxidation, or whether there is an electronic gain or loss.Turn left and turn right |In this reaction, carbon dioxide carbon has a valence of +4 price, after the reaction of carbon monoxide in the carbon price is +2, the carbon dioxide is reduced to carbon monoxide; elemental carbon has a valence of 0 by the price to rise to +2 price, is oxidized to carbon monoxide; carbon is oxidized to carbon dioxide reduction.

- Q: What are the potential applications of steel billets in the transportation sector?

- Steel billets have several potential applications in the transportation sector, including the production of various components such as engine parts, chassis, and body frames. They offer excellent strength-to-weight ratio, durability, and resistance to corrosion, making them ideal for manufacturing vehicles that can withstand harsh conditions. Additionally, steel billets can be easily formed into different shapes, allowing for the creation of complex and lightweight designs. Overall, their versatility and reliability make steel billets a valuable material in the transportation industry.

- Q: What does the billet of the steel plant refer to?And steel what is the difference?

- Many species, usually by chemical composition, production process, rolling shape, supply form, diameter, and use in the structure the classification of steel bars for concrete reinforcement refers to straight or strip steel plate reinforced concrete reinforcement steel, its shape is divided into round steel bar and deformed steel two. Steel bars in concrete under tensile stress.

Send your message to us

Steel Billets Q235 Q235 Q275 Q345 for Fire Door Billet Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords