120mm Steel Billets Q235 Q275 Q345 Professional Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

120mm Steel Billets Q235 Q275 Q345 Professional Steel

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

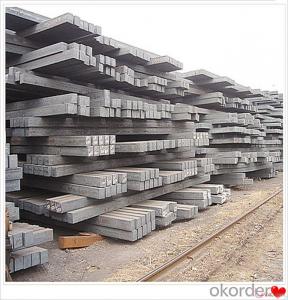

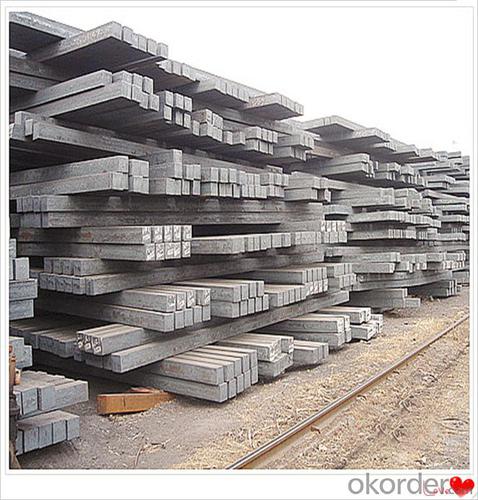

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: What are the common defects found in steel billets?

- Some common defects found in steel billets include surface cracks, internal voids or inclusions, improper segregation of alloying elements, and uneven grain structure. Other defects may include surface pitting, surface decarburization, or dimensional inconsistencies. These defects can affect the quality and strength of the steel billet, and may require further processing or corrective measures before the billet can be used for manufacturing purposes.

- Q: What are the different types of steel billet rolling processes?

- There are several types of steel billet rolling processes, including hot rolling, cold rolling, and warm rolling. Hot rolling involves heating the billet to a high temperature and then passing it through a series of rollers to shape it into the desired form. Cold rolling, on the other hand, is performed at room temperature and involves passing the billet through rollers to achieve a desired thickness or shape. Warm rolling is a combination of hot and cold rolling, where the billet is heated to a lower temperature compared to hot rolling but higher than room temperature. Each of these processes has its own advantages and is used for different applications in the steel industry.

- Q: How do steel billets contribute to the manufacturing of water and wastewater treatment equipment?

- Steel billets play a crucial role in the manufacturing of water and wastewater treatment equipment. These billets are essentially semi-finished steel products that are used as raw materials for various industrial applications. When it comes to the water and wastewater treatment industry, steel billets are utilized in the production of key components such as tanks, pipes, valves, and pumps. One of the primary reasons steel billets are favored in this industry is due to their excellent strength and durability. Water and wastewater treatment equipment are subjected to harsh operating conditions, including exposure to corrosive chemicals, high pressure, and extreme temperatures. Steel billets, made from high-quality materials such as carbon steel or stainless steel, offer the necessary strength and resistance to withstand these demanding environments. Furthermore, steel billets can be easily fabricated and formed into different shapes and sizes, making them highly versatile for manufacturing water and wastewater treatment equipment. These billets can be forged, rolled, or extruded to create components with precise specifications, ensuring a perfect fit and optimal functionality. The corrosion resistance of stainless steel billets is particularly valuable in water and wastewater treatment equipment. These billets are highly resistant to rust and corrosion, preventing contamination of the water supply and ensuring the longevity of the equipment. Stainless steel billets are also hygienic, making them suitable for applications where maintaining water quality and cleanliness is of utmost importance. Additionally, steel billets offer cost-effectiveness in the manufacturing process. The abundance of steel as a material and its recyclability make it a cost-efficient choice for producing water and wastewater treatment equipment. The long lifespan of steel components also reduces the need for frequent replacements, resulting in lower maintenance and operational costs. In summary, steel billets are essential in the manufacturing of water and wastewater treatment equipment due to their strength, durability, versatility, corrosion resistance, and cost-effectiveness. These billets provide the necessary raw materials to create robust and reliable components that can withstand the challenging conditions of the water treatment industry.

- Q: What is the role of steel billets in the construction of bridges and tunnels?

- The construction of bridges and tunnels heavily relies on steel billets, which are semi-finished steel products that undergo further processing to create various structural components for the construction industry. For bridges, steel billets are utilized to manufacture steel beams, girders, and columns, forming the core structure of the bridge. These components are essential for providing the required strength and stability to support the bridge's weight and the traffic it carries. Steel billets are chosen due to their high strength-to-weight ratio, making them ideal for constructing long-span and heavy-load bridges. Similarly, in tunnel construction, steel billets are used to create reinforcement bars or rebars. These rebars are embedded within the concrete walls and floors of tunnels, offering additional strength and support to withstand the immense pressure and weight of the surrounding soil or rock. Additionally, steel billets are also employed in fabricating tunnel linings, which protect the tunnel walls from erosion, corrosion, and other forms of deterioration. The utilization of steel billets in bridge and tunnel construction provides several advantages. Firstly, steel is a highly durable and resilient material, capable of withstanding extreme forces, temperature variations, and environmental conditions. This durability ensures the long-lasting nature and structural integrity of bridges and tunnels, reducing maintenance and repair costs over time. Secondly, steel billets can be easily shaped, molded, and welded into various intricate shapes and sizes, allowing for flexibility in design and construction. This versatility enables engineers to create innovative and efficient bridge and tunnel structures, accommodating different architectural and engineering requirements. Lastly, steel billets are renowned for their excellent load-bearing capacity, making them suitable for high-traffic areas such as bridges and tunnels. They can withstand heavy loads and distribute the weight evenly, minimizing the risk of structural failure or collapse. In conclusion, steel billets play a crucial role in the construction of bridges and tunnels by providing the necessary strength, durability, and flexibility. They form the core structure of these constructions, ensuring their stability, longevity, and ability to withstand various environmental and operational challenges.

- Q: How are steel billets used in the manufacturing of pipes?

- Pipes cannot be manufactured without steel billets, which are indispensable in this process. These semi-finished products made of steel act as the raw material for pipe production. The initial step involves selecting top-notch steel and melting it in a furnace to form molten steel alloy. After the steel has melted, it is poured into molds of specific sizes and shapes to create billets. These billets then undergo a cooling and solidification process. By solidifying, the steel achieves the desired structural properties, including strength and durability. Once the steel billets have cooled down, they undergo further processing to become seamless or welded pipes. In the case of seamless pipes, the billets are heated and pierced to form a hollow tube-like structure. These pierced billets are then elongated and stretched to achieve the desired diameter and thickness of the pipe. This technique, known as hot-rolling, results in seamless pipes with consistent dimensions and improved mechanical properties. On the other hand, welded pipes are manufactured using different methods. One common method is the electric resistance welding (ERW) process. It involves heating the billets and passing them through a series of rollers to shape them into a cylindrical form. The edges of the billets are then fused together using an electric current, creating a continuous weld. Other welding techniques, such as submerged arc welding (SAW) and high-frequency induction welding (HFIW), can also be employed to manufacture welded pipes from steel billets. In both seamless and welded pipe manufacturing, the quality of the steel billets is of utmost importance. It directly impacts the integrity and performance of the final product. The appropriate selection of steel grades and strict adherence to manufacturing standards are vital to produce pipes that can withstand high pressure, extreme temperatures, and corrosive environments. To sum up, steel billets are essential in the pipe manufacturing process. They act as the starting material for pipes, whether through the hot-rolling technique for seamless pipes or various welding methods for welded pipes. Utilizing high-quality steel billets and employing precise manufacturing processes allow for the production of pipes with the necessary strength, durability, and dimensional accuracy required for a wide range of industrial and commercial applications.

- Q: What are the main differences between carbon steel and alloy steel billets?

- Both carbon steel and alloy steel billets are utilized in various industries, but they differ in several key aspects. The primary discrepancy between carbon steel and alloy steel billets lies in their composition. Carbon steel billets consist primarily of iron and carbon, with carbon content typically ranging from 0.05% to 2.1%. This renders carbon steel comparatively more cost-effective and easier to manufacture than alloy steel. Conversely, alloy steel billets incorporate additional elements like manganese, nickel, chromium, and molybdenum, which are added to enhance specific steel properties. These alloying elements confer upon alloy steel superior strength, hardness, and resistance to corrosion compared to carbon steel. Another significant distinction between carbon steel and alloy steel billets pertains to their mechanical properties. Carbon steel billets are widely recognized for their high ductility and ease of shaping or forming, making them suitable for applications requiring flexibility and effortless machinability. Conversely, alloy steel billets possess higher tensile strength, toughness, and wear resistance due to the presence of alloying elements. This renders alloy steel billets ideal for applications necessitating high strength and wear resistance, such as in the construction, automotive, and aerospace industries. Moreover, the heat treatment processes for carbon steel and alloy steel billets also vary. Carbon steel billets are frequently subjected to heat treatment to enhance their hardness and strength, with common treatments encompassing quenching and tempering. Conversely, alloy steel billets can undergo a broader range of heat treatment processes, including annealing, normalizing, and precipitation hardening. These heat treatments serve to optimize the properties of alloy steel billets for specific applications, such as increasing strength or improving machinability. In conclusion, the primary disparities between carbon steel and alloy steel billets lie in their composition, mechanical properties, and heat treatment processes. Carbon steel predominantly comprises iron and carbon, while alloy steel incorporates additional alloying elements. Carbon steel possesses high ductility and is easily shaped, whereas alloy steel boasts superior strength, hardness, and resistance to corrosion. The heat treatment processes for these two steel types also differ, with alloy steel affording a wider array of treatment options.

- Q: What are the different types of machining processes used for shaping steel billets?

- There are several types of machining processes used for shaping steel billets, including turning, milling, drilling, and grinding. Turning involves rotating the billet against a cutting tool to remove excess material and create a desired shape. Milling uses rotary cutters to remove material from the billet, while drilling creates holes using a rotating cutting tool. Grinding involves using an abrasive wheel to remove material and achieve a smooth surface finish. These processes can be performed individually or in combination to achieve the desired shape and dimensions of the steel billet.

- Q: What are the potential applications of steel billets in the transportation aftermarket?

- Steel billets have various potential applications in the transportation aftermarket. They can be used for manufacturing various components such as engine parts, suspension systems, chassis, and body structures. Steel billets offer excellent strength, durability, and reliability, making them suitable for heavy-duty applications in the transportation industry. Additionally, their versatility allows for customization and adaptability to meet specific requirements. Overall, steel billets play a crucial role in enhancing the performance, safety, and efficiency of vehicles in the transportation aftermarket.

- Q: What is the role of steel billets in the manufacturing of automotive body panels?

- The manufacturing of automotive body panels heavily relies on steel billets, which are essential semi-finished metal products. These billets serve as the initial material for creating various components that compose a car's body. The primary rationale behind using steel billets in this process lies in their exceptional strength and durability. Automotive body panels need to endure different external forces and impacts, such as collisions, extreme weather conditions, and everyday wear and tear. Steel, being a robust and inflexible material, provides the necessary structural integrity to ensure the vehicle's safety and longevity. Furthermore, steel billets offer versatility in terms of design and customization. They can be effortlessly molded and shaped into different forms and sizes, enabling manufacturers to produce body panels with precise specifications. This adaptability allows for the creation of diverse car models with unique designs that meet the varied demands of consumers. Additionally, steel billets are favored for their cost-effectiveness. Steel is a widely available and relatively inexpensive material, making it a practical option for large-scale production. Moreover, its recyclability further reduces production costs and lessens environmental impact. In conclusion, the role of steel billets in the manufacturing of automotive body panels is of utmost importance. They provide the necessary strength, durability, versatility, and cost-effectiveness required for producing high-quality and dependable car bodies.

- Q: How do steel billets contribute to the mining industry?

- Steel billets are an important component of the mining industry as they play a crucial role in the production of various mining equipment and infrastructure. These billets, which are semi-finished steel products, are used to manufacture a wide range of tools and machinery required for mining activities. One of the primary applications of steel billets in the mining industry is in the production of mining machinery and equipment. These billets are used to create the structural components of heavy machinery such as excavators, bulldozers, and drilling rigs. The strength and durability of steel make it an ideal material choice for these applications, as it can withstand the harsh conditions and heavy loads encountered in mining operations. Steel billets are also utilized in the construction of mining infrastructure. Mining operations require the construction of various structures such as conveyor systems, processing plants, and storage facilities. Steel billets are used to fabricate the structural elements of these buildings, providing the necessary strength and stability to support the mining operations. In addition, steel billets are essential for manufacturing mining tools and equipment. Tools such as drills, hammers, and picks are made from steel billets due to their strength and hardness. These tools are used in various mining processes, including exploration, extraction, and processing of minerals. Furthermore, steel billets contribute to the mining industry by enabling the transportation of extracted minerals. Steel billets are used to manufacture rail tracks and wagons, which are essential for the transportation of minerals from the mining site to processing facilities or ports for export. Overall, steel billets are a vital component of the mining industry, supporting the production of machinery, infrastructure, tools, and transportation systems. Their strength, durability, and versatility make them an indispensable material in the mining sector, helping to drive its growth and efficiency.

Send your message to us

120mm Steel Billets Q235 Q275 Q345 Professional Steel

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords