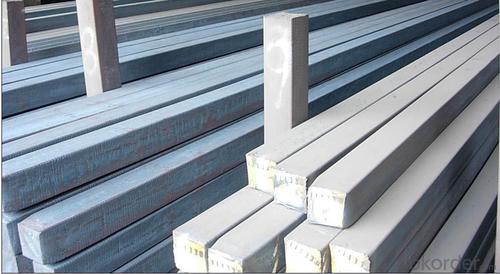

Square Steel Billet Q235 Grade Prime Quality 5#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Square Steel Billet Q235 Grade Prime Quality 5#

M. S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Main Feature Square Steel Billet Q235 Grade Prime Quality 5#

Raw elements(C,Fe,Ni,Mn,Cr,Cu.)---Smelted ingots by AOD finery---hot rolled into black suface---pickling in acid liquid---cold drawn----polished by automatically machine--- cutting into pieces---checking quanlity

Applications of Square Steel Billet Q235 Grade Prime Quality 5#

Widely Used in the areas such as Stainless Steel Fasteners, Chains, Kitchen and Sanitary wares, Furniture handles, Handrails, Electroplating and Electrolyzing pendants, Foods, Electron, Petroleum, Construction and Decoration, etc. Products have a high strength after cold-working. Electronic products parts, Medical appliance, Springs, Bus Inside and Outside packaging and building, Street Lamp Posts, etc. Decoration materials and Outdoor Publicity Billboard. Used for the products which have the Anti-Stress Corrosion requirement. Electron Products, Table-wares, Bolts, Nuts, Screen Meshes, Cumbustors and so on.

Specifications of Square Steel Billet Q235 Grade Prime Quality 5#

| Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

| Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

| Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

| Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

| 20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

| 3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

| 5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

FAQ of Square Steel Billet Q235 Grade Prime Quality 5#

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Can steel billets be used for making musical instruments?

- Yes, steel billets can be used for making musical instruments. While traditional musical instruments are often made from materials such as wood or brass, steel can also be used to create unique and modern instruments. Steel's strength and durability make it ideal for certain instruments, such as steel drums or steel guitars. Additionally, steel's versatility allows for the creation of intricate designs and shapes that can produce a wide range of sounds. However, it is important to note that the specific characteristics and properties of the steel used, such as its composition and thickness, will greatly impact the sound and quality of the instrument. Therefore, careful consideration and experimentation may be required to achieve the desired musical tones and effects when using steel billets for instrument making.

- Q: What are the different methods of hardness testing for steel billets?

- Steel billets can be tested for hardness using various methods, each with its own advantages and levels of accuracy. Some commonly used methods are: 1. Rockwell hardness testing: This method determines hardness by measuring the depth of indentation caused by a specific load on the surface of a steel billet. The hardness value is derived from the depth of penetration, making it a convenient and quick test. 2. Brinell hardness testing: In this method, a spherical indenter is used to create an impression on the surface of a steel billet under a specific load. The diameter of the resulting impression is measured to determine the hardness value. Brinell testing is particularly useful for large billets or materials with a coarse microstructure. 3. Vickers hardness testing: Vickers testing involves using a pyramidal diamond indenter to create an impression on the surface of a steel billet. The hardness value is calculated based on the diagonal length of the impression and the applied load. Vickers testing is suitable for various materials, including steel billets. 4. Knoop hardness testing: Similar to Vickers testing, Knoop hardness testing also uses a pyramidal diamond indenter. However, the indentation shape is elongated and narrower, allowing for measurements on smaller or thinner samples. This method is often used for precise and microhardness testing. 5. Leeb hardness testing: Leeb testing is a portable and non-destructive method that uses an impact device to measure the rebound hardness of a steel billet. The device strikes the surface with a small ball and measures the velocity of the rebound, which is then converted into a hardness value. This method is commonly used for on-site or in-field measurements. 6. Ultrasonic hardness testing: Ultrasonic testing measures the hardness of a steel billet by transmitting ultrasonic waves through the material and measuring the time taken for the waves to travel through the billet. This data is then converted into a hardness value. Ultrasonic testing is non-destructive and suitable for large or thick billets. It's important to consider that each hardness testing method has its own limitations and factors to consider. The choice of method will depend on factors such as the size, shape, and surface condition of the steel billet, as well as the desired accuracy and convenience of the testing process.

- Q: How are steel billets inspected for chemical composition?

- Steel billets are typically inspected for chemical composition through a process called spectroscopy. In this method, a small sample is taken from the billet and analyzed using specialized instruments such as optical emission spectroscopy or X-ray fluorescence spectroscopy. These instruments measure the emission or absorption of specific wavelengths of light to determine the concentration of different elements present in the steel. This allows for accurate assessment of the chemical composition of the billet, ensuring it meets the required specifications.

- Q: How do steel billets contribute to the manufacturing of renewable energy equipment?

- Steel billets are an essential component in the manufacturing of renewable energy equipment, such as wind turbines and solar panels. These billets are used to create sturdy and durable structures, including tower bases for wind turbines and frames for solar panels. Additionally, steel billets are crucial in the production of transmission and distribution infrastructure required for renewable energy systems. Their strength and versatility make them an indispensable material in the renewable energy industry, enabling the efficient and reliable generation of green energy.

- Q: What are the different methods of corrosion protection for steel billets?

- There exists a range of techniques for safeguarding steel billets against corrosion. Several commonly employed approaches include: 1. Coating: One highly effective means of corrosion protection involves applying a protective coating to the surface of steel billets. This can be accomplished through methods such as hot-dip galvanization, painting, or the application of a protective film. The coating acts as a barrier between the steel surface and corrosive elements in the surrounding environment, preventing direct contact and reducing the likelihood of corrosion. 2. Cathodic Protection: This method revolves around creating an electrochemical reaction to shield steel billets from corrosion. Cathodic protection can be achieved by utilizing sacrificial anodes or applying an impressed current. Sacrificial anodes, typically composed of zinc or magnesium, are connected to the steel billets and corrode sacrificially instead of the steel, thereby preserving it. Impressed current systems employ an external power source to supply the necessary current for steel protection. 3. VCI (Volatile Corrosion Inhibitors): VCI entails utilizing chemicals that emit vapors to establish a protective layer on the steel surface. These chemicals impede the corrosion process by neutralizing corrosive agents or forming a protective film on the steel surface. VCI can be implemented through various means, including coating, wrapping, or inserting VCI paper or packets into the packaging of steel billets. 4. Alloying: The introduction of alloying elements into the composition of steel billets can significantly enhance their corrosion resistance. For instance, the addition of chromium or nickel can augment the stainless properties of steel, rendering it more impervious to corrosion. Alloying can be performed during the initial production of steel billets or through post-treatment processes. 5. Environmental Control: The control of the environment in which steel billets are stored or utilized is of utmost importance in preventing corrosion. This encompasses measures such as maintaining appropriate humidity levels, avoiding exposure to corrosive chemicals or gases, and minimizing contact with water or moisture. By managing the environment, the likelihood of corrosion can be diminished, thereby safeguarding the steel billets. It is worth noting that the selection of a corrosion protection method hinges on various factors, including the expected extent of exposure to corrosive elements, the intended application of the steel billets, and cost considerations. Consequently, it is advisable to seek advice from corrosion experts or engineers to determine the most suitable method for a specific application.

- Q: What are the advantages of using steel billets in the manufacturing process?

- There are several advantages of using steel billets in the manufacturing process. Firstly, steel billets have a consistent composition and uniformity, which ensures better quality control during production. Secondly, steel billets can be easily molded into various shapes and sizes, allowing for flexibility in design and manufacturing. Additionally, steel billets possess high strength and durability, making them suitable for applications that require robust materials. Moreover, steel billets can be recycled and reused, making them an environmentally friendly choice. Overall, the use of steel billets enhances the efficiency, reliability, and sustainability of the manufacturing process.

- Q: How are steel billets used in the manufacturing of food processing equipment?

- Steel billets are an essential component in the manufacturing of food processing equipment. These billets, which are semi-finished steel products, serve as the raw material for the fabrication of various components and parts required in the construction of food processing machinery. Firstly, steel billets are used to create the main structural frame of the equipment. The strong and durable nature of steel makes it ideal for providing the necessary strength and stability to support the entire machinery. The billets are cut and shaped into the desired dimensions to form the framework, ensuring that it can withstand the rigorous demands of industrial food processing. Moreover, steel billets are also used to manufacture specific components within the equipment. For instance, they are utilized to create cutting blades, grinding discs, and mixing paddles that are crucial in the food processing process. These components need to be robust and resistant to wear and corrosion, and steel billets offer the ideal material to meet these requirements. In addition, steel billets are often used to construct food processing equipment that requires high levels of hygiene and cleanliness. Stainless steel billets, in particular, are favored in such applications due to their inherent resistance to rust and corrosion. These billets are used to fabricate parts that come into direct contact with food, such as storage tanks, conveyors, and mixing chambers, ensuring that the food processing equipment is safe and hygienic. Furthermore, steel billets are employed in the manufacturing of heat exchangers and boilers used in food processing. These billets are designed to withstand high temperatures and pressure, making them suitable for applications that involve cooking, sterilization, or pasteurization of food products. In conclusion, steel billets play a crucial role in the manufacturing of food processing equipment. From providing structural support to fabricating specific components, they contribute to creating robust, efficient, and hygienic machinery that is essential for the food industry.

- Q: How are steel billets used in the production of agricultural harvesting equipment?

- Steel billets are used as a raw material in the production of agricultural harvesting equipment. They are melted, cast, and then shaped into various components such as blades, teeth, and shafts that are essential for the efficient functioning of the equipment. The strength and durability of steel make it an ideal choice for withstanding the demanding conditions and heavy-duty operations involved in agriculture.

- Q: What is the role of steel billets in the construction of railway stations?

- Steel billets are essential in constructing railway stations, serving as semi-finished steel products that are typically rectangular or square in shape. They function as raw materials for various construction purposes. Within the realm of railway stations, steel billets are primarily utilized to fabricate structural components like beams, columns, and trusses. These components provide the necessary strength and stability to support the weight of the station building, platforms, and any associated structures. A key advantage of employing steel billets in railway station construction lies in their high strength-to-weight ratio. Steel is widely recognized for its exceptional strength, making it an ideal material for supporting heavy loads. By incorporating steel billets, engineers can design and construct railway stations capable of enduring the constant traffic and heavy footfall characteristic of these public spaces. Furthermore, steel billets offer exceptional durability, corrosion resistance, and fire resistance, all of which are vital factors in ensuring the long-term safety and structural integrity of railway stations. These properties establish steel billets as a reliable and cost-effective choice for construction projects prioritizing safety and longevity. Moreover, steel billets can be easily shaped and fabricated into various sizes and dimensions, allowing for flexibility in design and construction. This versatility enables architects and engineers to create aesthetically appealing and functional railway station structures tailored to the specific project requirements. In summary, steel billets play a crucial role in railway station construction by providing the necessary strength, durability, and versatility required for the structural components supporting these vital transportation hubs. By utilizing steel billets, railway station construction projects can be completed efficiently, guaranteeing the safety and comfort of passengers for years to come.

- Q: How are steel billets used in the production of crankshafts?

- Crankshafts rely on steel billets for their production, as these billets are essential in forming the foundation of this intricate component. Obtained through continuous casting or rolling of molten steel, steel billets are semi-finished products typically found in square or rectangular shapes. To create a crankshaft, the initial step involves heating the steel billet to a specific temperature, usually achieved through induction heating. This process enhances the billet's malleability, making it easier to shape. Once heated, the billet is placed into a forging machine, where it undergoes a series of compressive forces and plastic deformation. This gradual transformation results in the desired shape of the crankshaft. Throughout the forging process, the steel billet experiences immense pressure to ensure the metal grain structure aligns optimally. This alignment enhances the strength and durability of the crankshaft. Precise shaping of the crankshaft's main bearing journals, crankpin journals, and counterweights is achieved through carefully controlled forging techniques. Following the forging process, the partially finished crankshaft undergoes various machining operations, such as milling, turning, and grinding. These operations refine the crankshaft's dimensions and surface finish to meet the required specifications for smooth operation and efficient power transmission. In conclusion, steel billets are crucial raw materials in the production of crankshafts. Through the forging process, these billets are transformed into strong and resilient crankshafts capable of withstanding the demanding conditions of engines. The use of steel billets contributes to the production of crankshafts with superior strength, durability, and performance, making them vital components in the automotive and machinery industries.

Send your message to us

Square Steel Billet Q235 Grade Prime Quality 5#

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords