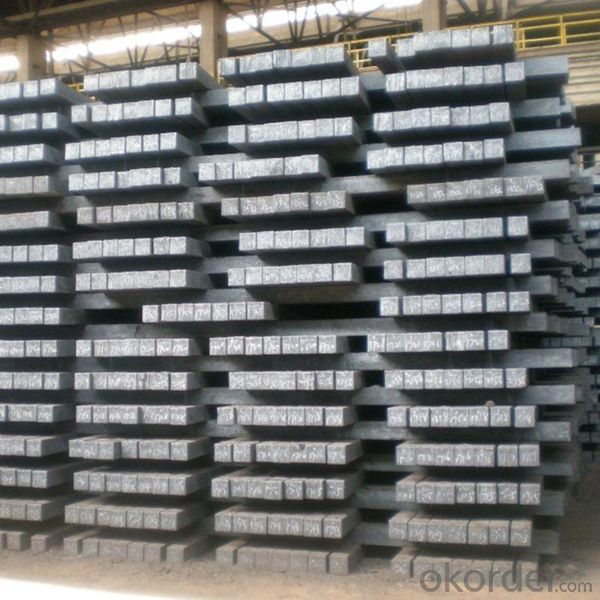

TK 440 superior hot rolled Carbon Steel Billets Square Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

TK 440 superior hot rolled Carbon Steel Billets Square Billets

Size:30*30mm-150*150mm

Standard: GB,BS,ASTM

Grade: Q195/215/235/345/45#/3SP/5SP,ect

Application: Carbon structural steel, alloy structural steel, gear steel, spring steel,

bearing steel, etc.

Packaging Detail: exporting standard packing in mill or as request

Delivery Detail: within 15-30 days after receiving deposits or original LC

The Billets produced by the company can be broadly divided into three main types i.e.

1. M.S. Billets

2. CRS Billets

3. Special Alloy Billets

M.S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used for rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Square steel billet

1.Chemical Analysis | |||

Grade | Carbon(%) | Manganese(%) | Silicon(%) |

A | 0.14~0.22 | 0.30~0.65 | Max0.30 |

B | 0.12~0.20 | 0.37~0.67 | Max0.30 |

C | Max0.18 | 0.35~0.80 | Max0.30 |

D | Max0.17 | 0.35~0.80 | Max0.35 |

2.Mechnical Properties | |||

Tensile Strength(σb/Mpa) | Elongation(δ5/%) | ||

375---500 | ≥26(a≤16mm) | ||

3.basic information | |||

length | Spectfication(mm) | Material quality | Executive standard |

6m | 120*120 | Q235 | GB700-88 |

4.Trade information | |||

Price terms | Payment terms | Delivery time | Packing |

FOB/ CIF | T/T, L/C | Within 30 days | bundles |

- Q: What are the main factors affecting the machinability of stainless steel billets?

- The main factors affecting the machinability of stainless steel billets include the composition and microstructure of the steel, the hardness and work hardening characteristics, the cutting tool material and geometry, the cutting parameters such as cutting speed, feed rate, and depth of cut, and the cooling and lubrication methods used during machining.

- Q: What are the different methods of surface treatment for steel billets?

- Various methods exist for surface treatment of steel billets, each serving a distinct purpose and offering unique advantages. Among the most commonly employed techniques are: 1. Pickling: This involves immersing the steel billets in an acid solution to eliminate surface impurities like rust or scale. Pickling enhances surface finish and readies the steel for subsequent treatment or processing. 2. Shot blasting: In this method, high-speed steel shots or grits are used to bombard the steel billets, eliminating surface contaminants and creating a uniform texture. Shot blasting is frequently employed to remove rust, scale, or paint, and it can enhance the adhesion of subsequent coatings or paints. 3. Galvanizing: This treatment entails coating the steel billets with a layer of zinc to provide corrosion resistance. Galvanizing can be accomplished through hot-dip galvanizing, where the steel is immersed in a molten zinc bath, or through electroplating, where a thin layer of zinc is deposited on the surface using an electric current. 4. Painting or powder coating: Steel billets can be painted or coated with powder to deliver both aesthetic appeal and protection against corrosion. Paints or powder coatings create a barrier between the steel surface and the environment, preventing moisture and other corrosive agents from reaching the metal. 5. Passivation: This method requires treating the steel billets with a chemical solution, typically an acid, to remove any free iron or iron oxide from the surface. Passivation enhances the corrosion resistance of stainless steel and other alloys by creating a passive oxide layer that safeguards against further oxidation or rusting. 6. Nitriding: Nitriding is a surface hardening treatment where the steel billets are exposed to an atmosphere rich in nitrogen at elevated temperatures. This process diffuses nitrogen into the steel's surface, forming a hardened layer that enhances wear resistance and improves fatigue strength. 7. Chrome plating: Steel billets can be coated with a layer of chromium through electroplating, providing enhanced corrosion resistance and a glossy appearance. Chrome plating is frequently utilized in applications where aesthetics and durability are crucial, such as automotive parts or decorative fixtures. These examples represent only a fraction of the available surface treatment methods for steel billets. The selection of a particular technique depends on factors such as the desired outcome, the specific properties required, and the intended application of the steel billets.

- Q: How do steel billets contribute to the overall corrosion protection of a structure?

- Steel billets, classified as semi-finished steel products, play a crucial role in safeguarding structures against corrosion. They contribute to corrosion protection through multiple means: 1. Superior steel composition: Steel billets are crafted from top-notch steel that comprises different alloying elements, like chromium, nickel, and molybdenum. These elements amplify the steel's resistance to rust and corrosion, making it less vulnerable. 2. Protective layering: Steel billets are often coated with protective layers, such as zinc or epoxy coatings. These coatings function as a barrier between the steel surface and the external environment, obstructing moisture, oxygen, and other corrosive substances from reaching the steel and causing corrosion. 3. Enduring strength: Steel billets are renowned for their remarkable strength and durability. When utilized in construction, they provide a robust foundation and structural support. This strength and durability minimize the likelihood of structural damage and corrosion, guaranteeing the stability and longevity of the structure. 4. Welding capability: Steel billets possess exceptional weldability, facilitating easy and efficient joining of steel components during construction. Proper welding techniques and materials can further augment the structure's corrosion resistance by preserving the integrity and continuity of the protective coatings. 5. Maintenance and repair: In the event of damage or corrosion on the structure, steel billets can be readily replaced or repaired. This ensures that the affected area can be rectified without compromising the overall integrity and corrosion protection of the structure. Regular maintenance and repair of steel billets contribute to the long-term corrosion protection of the entire structure. In conclusion, steel billets contribute significantly to the overall corrosion protection of structures through their high-quality composition, protective coatings, durability, weldability, and ease of maintenance and repair. By incorporating steel billets into construction projects, engineers and architects can ensure the longevity, safety, and corrosion resistance of structures in diverse environments.

- Q: What is the role of steel billets in the manufacturing of industrial boilers?

- The role of steel billets in the manufacturing process of industrial boilers is crucial. These billets act as the raw material from which the various components of the boiler are formed. Industrial boilers are complex structures that require durable materials of high quality to withstand the harsh operating conditions. Steel billets, typically made from carbon steel or alloy steel, possess excellent strength and corrosion resistance properties. They undergo a heating process before being shaped into different forms such as plates, tubes, or rods through rolling, extrusion, or forging. These formed components are then processed and assembled to create the boiler. During the manufacturing process, steel billets are used to fabricate important boiler components including the shell, tubes, and flues. The shell, made from steel plates, forms the main body of the boiler, while the tubes and flues allow for the passage of hot gases and water. Steel billets ensure the structural integrity of these components, enabling them to withstand high temperatures and pressures without deformation or failure. Additionally, steel billets are utilized in the creation of other auxiliary components of industrial boilers such as supports, brackets, and fittings. These components are vital for the proper functioning and installation of the boiler, ensuring stability, efficiency, and safety. In summary, steel billets are essential to the manufacturing of industrial boilers due to their ability to provide the necessary strength, durability, and versatility required to withstand demanding operating conditions. The utilization of high-quality steel billets guarantees that the boilers are reliable, long-lasting, and capable of meeting the rigorous performance standards expected in industrial applications.

- Q: How do steel billets contribute to the overall aesthetics of a structure?

- Steel billets, which are essentially semi-finished steel products, play a significant role in enhancing the overall aesthetics of a structure. While their primary purpose is to provide strength and support, their visual appeal should not be underestimated. First and foremost, steel billets are responsible for the creation of various architectural elements, such as columns, beams, and decorative features. These elements not only serve structural purposes but also contribute to the overall aesthetics of the building. The clean lines and sleek appearance of steel billets can give a modern and contemporary feel to the structure, adding a touch of sophistication and elegance. Moreover, steel billets can be manipulated and shaped into intricate designs and patterns, making them highly versatile in terms of aesthetics. Whether it is a grand entrance gate, a unique staircase railing, or an ornate decorative panel, steel billets can be molded and fabricated to create visually appealing and eye-catching features that enhance the overall charm of the structure. Furthermore, steel billets can be finished with various coatings, such as paint, powder coating, or galvanization, which not only provide protection against corrosion but also contribute to the aesthetic appeal. These finishes allow for customization, as they can be chosen to complement the overall design and color scheme of the structure, creating a cohesive and visually pleasing look. In addition, steel billets can be used in combination with other materials, such as glass or wood, to create stunning architectural features. The contrast between the strength and rigidity of steel and the transparency or warmth of other materials can create a visually striking effect, adding depth and interest to the structure's design. Lastly, steel billets offer a sense of durability and timelessness to the structure. The inherent strength and resilience of steel give the impression of solidity and longevity, which are essential factors in creating an aesthetically pleasing building. The sleek and modern appearance of steel billets can also evoke a sense of progress and innovation, enhancing the overall aesthetic appeal of the structure. In conclusion, steel billets contribute to the overall aesthetics of a structure by providing structural support, allowing for intricate designs, offering customization options, creating contrasts with other materials, and conveying a sense of durability and timelessness. Their visual appeal, along with their strength and versatility, makes steel billets an essential component in creating an aesthetically appealing and architecturally pleasing structure.

- Q: What are the different surface treatments for improved corrosion resistance in steel billets?

- Steel billets can undergo different surface treatments to enhance their resistance to corrosion. These treatments aim to establish a protective barrier on the steel's surface, preventing corrosive agents from reaching the metal beneath. Some commonly used surface treatments for improved corrosion resistance in steel billets include: 1. Hot-dip galvanizing: Immersing the steel billets in molten zinc creates a galvanized coating, which is a zinc-iron alloy. This coating offers excellent corrosion resistance and prolongs the lifespan of the steel billets. 2. Electroplating: Through electroplating, a thin layer of metal such as zinc or nickel is applied to the steel billets using an electric current. This layer acts as a protective barrier against corrosion and provides an attractive finish. 3. Powder coating: By applying a dry powder mixture of resin and pigment to the steel billets and heating it, a durable and corrosion-resistant layer is formed. Powder coating is available in various colors and finishes. 4. Paint coatings: Applying corrosion-resistant paint to steel billets creates a protective barrier that hinders moisture and corrosive agents from reaching the steel. Multiple layers of paint can be added for enhanced durability and longevity. 5. Passivation: Passivation is a chemical process that eliminates free iron and contaminants from the steel billets' surface. This process prevents corrosion and encourages the formation of a protective oxide layer. Passivation is often combined with other surface treatments like electroplating or powder coating to enhance corrosion resistance. It is important to consider factors such as the billets' operating environment, desired lifespan, and cost considerations when choosing a surface treatment for improved corrosion resistance. A thorough evaluation of specific requirements and professional consultation are crucial in determining the most suitable treatment option.

- Q: What are the specifications for steel billets used in the aerospace industry?

- The aerospace industry demands highly precise and stringent specifications for steel billets. These billets must adhere to specific standards to guarantee the safety and durability of aircraft components. Firstly, the steel utilized for aerospace billets must possess outstanding strength and toughness. It must exhibit a high tensile strength and the ability to withstand extreme forces and stresses encountered during flight. Additionally, the steel must demonstrate excellent fracture resistance to minimize the risk of catastrophic failure. Moreover, the steel billets must possess exceptional resistance to corrosion and oxidation. This is crucial as aircraft frequently operate in harsh environments, such as high altitudes and exposure to various chemicals. The steel should resist rust, pitting, and other forms of degradation that can compromise its structural integrity over time. Furthermore, the steel billets employed in aerospace applications must exhibit precise dimensional tolerances and uniformity. They should be manufactured according to exact specifications to ensure consistency in the production of aircraft components. This entails precise size, shape, and surface finish, which are vital for proper fitting and assembly. Regarding chemical composition, the steel used for aerospace billets may vary depending on the specific application and component being manufactured. However, it typically includes elements like carbon, manganese, chromium, nickel, and molybdenum. These alloying elements enhance the mechanical properties of the steel, such as hardness, toughness, and heat resistance. Additionally, the steel billets utilized in the aerospace industry undergo rigorous testing and quality control procedures. This includes non-destructive testing methods such as ultrasonic inspection, magnetic particle inspection, and dye penetrant inspection to identify any internal defects or discontinuities. In summary, the specifications for steel billets used in the aerospace industry encompass exceptional strength, toughness, corrosion resistance, dimensional accuracy, and precise chemical composition. These stringent requirements ensure the reliability and safety of aircraft components, enabling them to withstand the demanding conditions experienced during flight.

- Q: What are the potential applications of steel billets in the transportation sector?

- Steel billets have several potential applications in the transportation sector, including the production of various components such as engine parts, chassis, and body frames. They offer excellent strength-to-weight ratio, durability, and resistance to corrosion, making them ideal for manufacturing vehicles that can withstand harsh conditions. Additionally, steel billets can be easily formed into different shapes, allowing for the creation of complex and lightweight designs. Overall, their versatility and reliability make steel billets a valuable material in the transportation industry.

- Q: What is the role of steel billets in the production of valves and fittings?

- Valves and fittings, which are crucial in industries like oil and gas, petrochemical, and water treatment, rely heavily on steel billets. These billets, derived from molten steel, serve as the starting point for producing these components. To meet specific requirements, the billets are cast into shapes like round, square, or rectangular. The usage of steel billets enables manufacturers to maintain consistent quality and performance in valves and fittings. The selection process involves considering factors such as chemical composition, mechanical properties, and microstructure to guarantee the desired characteristics in the end product. After obtaining the steel billets, they undergo various manufacturing processes like forging, machining, and heat treatment. These processes further enhance the strength, integrity, and functionality of the final valve and fitting components. One of the advantages of steel billets is their versatility in customization. They can be easily cut, shaped, and formed to create valves and fittings with different sizes, configurations, and designs. This flexibility allows them to meet the specific requirements of different applications and industries. In summary, steel billets serve as the raw material for valves and fittings, playing a vital role in their production. Their strength, durability, and customization capabilities ensure the reliability and performance of these components in various industrial settings.

Send your message to us

TK 440 superior hot rolled Carbon Steel Billets Square Billets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords