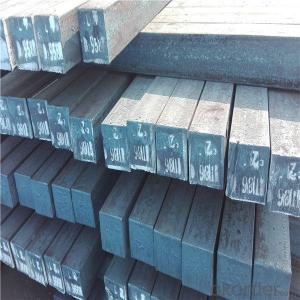

Hot Rolled Steel Square Steel Billet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Billet at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

.

Product Advantages:

OKorder's Steel Billet are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

We procure world class quality steel billets which meets the specific requirements of the clients

The Billets produced by the company can be broadly divided into three main types i.e.

M.S. Billets

CRS Billets

Special Alloy Billets

M.S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used fro rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

The following are the sizes of Billets available with Shyam Steel Industries Ltd.:

100 X 100

120x120

150 X 150

Physical Properties:

Description

As per IS 2830

Shyam Billets

Bend (max.) 5 mm per meter >= 5 mm per meter

Carbon (max.) 3mm per meter >= 3 mm per meter

Length 3 mt - 13 mt 3 mt - 9 mt

Chemical Properties:

Ladle Analysis:

Designation

Carbon

Manganese

C15 0.12-0.18 0.30-0.60

C18 0.15-0.21 0.30-0.60

C20 0.17-0.23 0.30-0.60

C15 MMn 0.12-0.18 0.60-1.00

C18 MMn 0.15-0.21 0.60-1.00

C20 MMn 0.17-0.23 0.60-1.00

C15 HMn 0.12-0.18 1.00-1.50

C18 HMn 0.15-0.21 1.00-1.50

C20 HMn

0.17-0.23 1.00-1.50

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: How is steel tubing used in manufacturing?

- Steel tubing is commonly used in manufacturing for various applications such as structural support, fluid transportation, and conveying materials. It is often used in the construction of buildings, bridges, and machinery due to its strength, durability, and resistance to corrosion. Additionally, steel tubing is used in the production of automobiles, appliances, and various industrial equipment, where it provides a reliable and efficient means of conveying fluids, gases, and materials. Overall, steel tubing plays a crucial role in the manufacturing industry by providing a versatile and cost-effective solution for numerous applications.

- Q: How do steel products contribute to the food and beverage industry?

- Steel products contribute to the food and beverage industry in various ways. Steel is commonly used in the construction of commercial kitchens and food processing plants due to its durability, hygiene, and resistance to corrosion. Stainless steel equipment, such as work surfaces, sinks, and storage units, provide a clean and safe environment for food preparation and storage. Steel tanks and containers are used for transportation and storage of food and beverages, ensuring their freshness and preventing contamination. Additionally, steel packaging, such as cans and beverage containers, offers a secure and long-lasting solution for preserving and distributing food and drinks.

- Q: What is the role of steel in the manufacturing of appliances?

- Steel plays a crucial role in the manufacturing of appliances as it provides strength, durability, and corrosion resistance. It is used to construct the framework, outer casing, and internal components of appliances such as refrigerators, ovens, and washing machines. Steel's high strength-to-weight ratio allows for sturdy and reliable appliances, while its corrosion resistance ensures longevity. Moreover, steel can be easily shaped and molded into complex forms, making it an ideal material for various appliance components.

- Q: What are the properties of high-strength low-alloy (HSLA) steel?

- High-strength low-alloy (HSLA) steel is characterized by its superior mechanical properties, including high strength, good toughness, and excellent corrosion resistance. It typically contains small amounts of alloying elements such as carbon, manganese, silicon, and phosphorus, which enhance its strength while maintaining good weldability and formability. HSLA steel is widely used in various industries, including automotive, construction, and manufacturing, where lightweight yet durable materials are required.

- Q: What are the common types of steel products used in the telecommunications industry?

- Some common types of steel products used in the telecommunications industry include steel poles, towers, and cabinets. These steel structures provide the necessary support and protection for telecommunication equipment and infrastructure.

- Q: How are steel products tested and certified for quality and performance?

- Steel products are tested and certified for quality and performance through a rigorous process that involves various tests and assessments. These include mechanical tests, such as tensile strength, hardness, and impact resistance tests, as well as chemical composition analysis to ensure the steel meets the required standards. Additionally, dimensional inspections and non-destructive testing methods, such as ultrasonic testing and visual inspections, are conducted to detect any defects or flaws. Once these tests are successfully passed, a certification is issued to guarantee the quality and performance of the steel product.

- Q: What are the different types of steel fasteners and connectors available?

- There are several types of steel fasteners and connectors available, including screws, bolts, nuts, washers, rivets, and nails. Each type serves a specific purpose and is designed to provide a secure and reliable connection in various applications.

- Q: What are the factors to consider while selecting steel products for a specific application?

- When selecting steel products for a specific application, there are several factors to consider. These include the required strength and durability, corrosion resistance, cost, availability, and the specific conditions and environment in which the steel will be used. Additionally, factors such as the required shape, size, and weight of the steel product, as well as any special properties or certifications needed for the application, should also be taken into account.

- Q: What are the different types of steel wire ropes and their uses in offshore drilling operations?

- There are several types of steel wire ropes commonly used in offshore drilling operations. These include drilling lines, sandline cables, and guy wires. Drilling lines are heavy-duty wire ropes designed to support the weight of the drill string and transport drilling fluids. They are used to lower and raise the drill bit, as well as to rotate the drill string during drilling operations. Sandline cables, on the other hand, are lighter wire ropes used for well servicing and workover operations. They are primarily used to lower and retrieve equipment, such as pumps and tools, into and out of the wellbore. Lastly, guy wires are steel wire ropes used to support and stabilize offshore drilling platforms or structures. They help to counterbalance the weight and forces acting on the structure, ensuring stability and safety. Overall, steel wire ropes play a crucial role in offshore drilling operations, providing strength, durability, and reliability necessary for various tasks and applications.

- Q: What are the different types of steel tanks and their applications in the food processing industry?

- There are several types of steel tanks used in the food processing industry, including stainless steel tanks, carbon steel tanks, and alloy steel tanks. Stainless steel tanks are the most common type, known for their corrosion resistance and hygienic properties. They are widely used for storing and processing various food products such as dairy, beverages, sauces, and oils. Carbon steel tanks, on the other hand, are less expensive but require additional measures to prevent corrosion. They are commonly used for bulk storage of dry food ingredients like grains, flour, and sugar. Alloy steel tanks are a specialized type that offers enhanced strength and durability. They are utilized in food processing applications that involve high-pressure processes or extreme temperature conditions, such as canning or sterilization. Overall, steel tanks play a crucial role in the food processing industry, ensuring proper storage, transportation, and processing of food products while maintaining hygiene and safety standards.

Send your message to us

Hot Rolled Steel Square Steel Billet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords