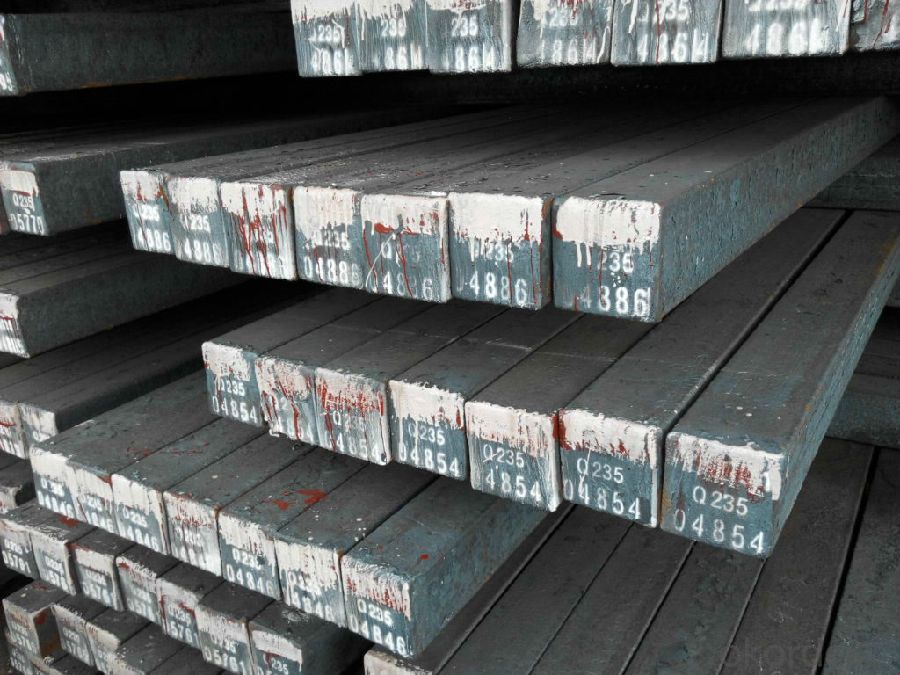

Steel Billets CarbonQ275/3SP in China Square Billets for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

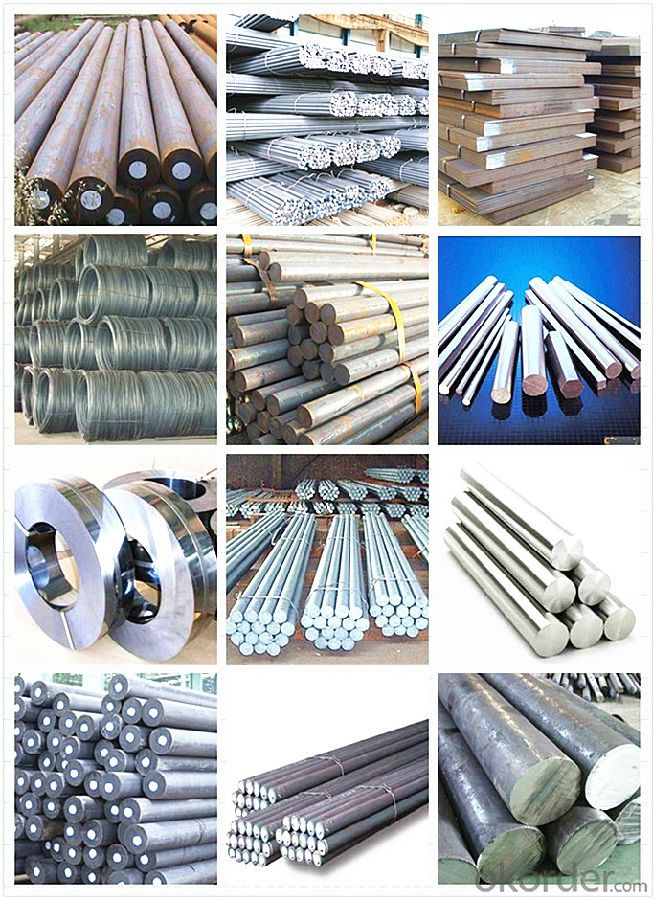

You Might Also Like

Description of Steel Billets CarbonQ275/3SP in China Square Billets for Construction

We procure world class quality steel billets which meets the specific requirements of the clients

The Billets produced by the company can be broadly divided into three main types i.e.

Festures of Steel Billets CarbonQ275/3SP in China Square Billets for Construction

Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products. Billets are used fro rolling of CRS TMT Re-Bars..

Product Size of Steel Billets CarbonQ275/3SP in China Square Billets for Construction

| GRADE | SIZE | APPLICATION |

Q195/ 215 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon of Steel Billets CarbonQ275/3SP in China Square Billets for Construction

Q195/ 215 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.06-0.12 | 0.15-0.30 | 0.35-0.50 | 0.045% Max | 0.045Max |

Technology process of Steel Billets CarbonQ275/3SP in China Square Billets for Construction

1.Heat the EVA film

2.Cover the heated EVA film on the mould(can be made from wood or aluminum)

3.Spray a coating in a certain baume degree

4.Put on the empty blask

5.Sand-up the flask and vibrate to compaction

Packaging & Delivery of Steel Billets CarbonQ275/3SP in China Square Billets for Construction

Packaging Details:containers

Delivery Detail:Complete one set of equipment needs for three months

The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

Products Show

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Can steel billets be coated for improved aesthetic appearance?

- Improving the aesthetic appearance of steel billets is possible by applying coatings. These coatings, including paints, powder coatings, and plating, can enhance the visual appeal of the steel billets. They serve multiple purposes such as providing a decorative finish, protecting against corrosion, and increasing the overall durability of the steel billets. Moreover, these coatings can be tailored to meet specific aesthetic demands, allowing for increased design flexibility in terms of colors, textures, and patterns. Consequently, coating steel billets is a widely adopted practice across various industries such as construction, automotive, and consumer goods, to achieve a better aesthetic appearance.

- Q: What is the role of steel billets in the manufacturing of construction cranes?

- In the manufacturing process of construction cranes, steel billets play a vital role as they are the raw materials used to produce various crane components. These billets are essentially partially finished steel products that are shaped and sized into rectangles or squares. A primary purpose of steel billets in crane manufacturing is the production of structural members like beams, columns, and braces. These components provide the necessary strength and stability to support the crane's weight and the loads it carries. Steel billets are chosen for their high strength and durability, enabling the crane to withstand heavy loads and adverse working conditions. Furthermore, steel billets are utilized to manufacture the crane's boom, jib, and lifting mechanisms. These parts experience significant stress and forces during crane operation, and the superior mechanical properties of steel billets make them ideal for ensuring the crane's structural integrity and longevity. Additionally, steel billets are used in the fabrication of counterweights for the crane. Counterweights are crucial for balancing the load being lifted and preventing the crane from tipping over. By using steel billets, manufacturers can create counterweights that are sufficiently heavy to counterbalance the loads without compromising the overall stability and safety of the crane. Moreover, steel billets are often employed in the production of other crane components such as pins, bolts, and connectors. These small yet essential parts contribute to the overall performance and functionality of the crane, ensuring smooth operation and structural integrity. In summary, steel billets act as the fundamental building blocks for the manufacturing of construction cranes, providing the necessary strength, durability, and stability required for these robust machines. Without steel billets, it would be nearly impossible to produce cranes capable of lifting heavy loads and withstanding the demanding conditions of construction sites.

- Q: What are the potential applications of steel billets in the chemical aftermarket?

- Steel billets have a wide range of potential applications in the chemical aftermarket. One of the key uses of steel billets is in the production of various chemical processing equipment. These billets can be used to manufacture reactors, heat exchangers, columns, and other critical components that are used in chemical plants. Furthermore, steel billets are also utilized in the construction of storage tanks for storing chemicals. These tanks need to be strong, durable, and resistant to corrosion, and steel billets provide the necessary properties to meet these requirements. In addition, steel billets find applications in the fabrication of pipelines and piping systems used for transporting chemicals. The high strength and resistance to temperature and pressure make steel billets an ideal choice for constructing pipelines that can handle corrosive and hazardous chemicals. Moreover, steel billets can be shaped and formed into various fittings and flanges that are essential components in chemical systems. These fittings and flanges are used to connect different sections of piping, valves, and other equipment, ensuring a secure and leak-free operation. Overall, the potential applications of steel billets in the chemical aftermarket are vast and diverse. From manufacturing chemical processing equipment to constructing storage tanks, pipelines, and fittings, steel billets play a crucial role in ensuring the safe and efficient operation of chemical facilities.

- Q: How are steel billets used in the manufacturing of construction machinery parts?

- Steel billets are used in the manufacturing of construction machinery parts as the starting material for forging, casting, or machining processes. They are heated and shaped into various components such as gears, shafts, frames, and structural elements, providing the necessary strength, durability, and precision required for construction machinery.

- Q: What is the role of steel billets in the manufacturing of structural steel bridges?

- Structural steel bridges heavily rely on steel billets, which are essential semi-finished products utilized as the raw material for manufacturing various steel products, including these bridges. The initial step involves heating the steel billets and passing them through a series of rolling mills to shape them accordingly. This rolling process ensures that the billets are converted into elongated, slender sections suitable for bridge construction. Once the steel billets have been rolled into the desired forms, they undergo further processing and fabrication to create the necessary components for structural steel bridges. These components encompass beams, columns, girders, and other vital elements that contribute to the bridge's strength, stability, and load-bearing capabilities. The utilization of steel billets in the production of structural steel bridges provides numerous advantages. Firstly, steel possesses an exceptional strength-to-weight ratio, rendering it an ideal material for constructing bridges capable of withstanding heavy loads while remaining relatively lightweight. Moreover, steel's versatility allows for the creation of intricate bridge designs that can accommodate diverse architectural and engineering requirements. Furthermore, steel billets exhibit high durability and resistance to environmental factors like corrosion, which is crucial for ensuring the long-term integrity and safety of the bridge structure. This durability ultimately contributes to the bridge's extended lifespan, leading to reduced maintenance and replacement costs over time. In conclusion, steel billets serve as the fundamental building blocks for the manufacturing of structural steel bridges. Through the rolling and fabrication processes, these billets are transformed into various components that collectively provide strength, stability, and durability to the bridge. The utilization of steel billets enables the construction of bridges capable of withstanding heavy loads, maintaining a lightweight nature, and enduring environmental factors, thereby ensuring the bridge's long-term integrity and safety.

- Q: How can the quality of steel billets be improved?

- There are several methods and techniques that can be employed to improve the quality of steel billets. Below are some approaches that can assist in enhancing the quality of steel billets: 1. Raw Material Selection: The quality of steel billets heavily relies on the selection of raw materials. Opting for high-quality raw materials, such as top-grade iron ore and scrap metal, can considerably enhance the quality of billets. 2. Melting and Refining: The melting and refining process play a pivotal role in enhancing steel billet quality. The utilization of advanced melting practices, like electric arc furnaces (EAF) or induction furnaces, can aid in achieving a more uniform and controlled melting process, reducing impurities, and achieving the desired chemical composition. 3. Deoxidation and Degassing: It is essential to employ appropriate deoxidation and degassing techniques to eliminate impurities and gases from the molten metal. This can be accomplished by incorporating suitable deoxidizers and utilizing vacuum degassing processes that efficiently remove unwanted gases, thus enhancing the quality of steel billets. 4. Continuous Casting Process: The implementation of a modern continuous casting process can significantly improve the quality of steel billets. Continuous casting ensures a more consistent structure, reduces segregation, and minimizes the formation of defects commonly associated with traditional ingot casting methods. 5. Heat Treatment: The application of suitable heat treatment processes, such as annealing, quenching, and tempering, can further enhance the mechanical properties and overall quality of steel billets. Heat treatment helps refine the microstructure, improving the strength, hardness, and other desired characteristics of the steel. 6. Quality Control: A robust quality control system is crucial to ensure the production of high-quality steel billets. Regular monitoring and testing should be conducted throughout the production process to promptly identify and rectify any deviations or quality issues. 7. Skilled Workforce: Employing a skilled and knowledgeable workforce is vital for improving the quality of steel billets. Well-trained technicians and operators can effectively implement various quality improvement techniques and address any production challenges that may arise. By incorporating these methods and techniques, steel manufacturers can enhance the quality of steel billets, resulting in improved mechanical properties, superior surface finish, and increased customer satisfaction.

- Q: What is the global production and consumption of steel billets?

- The global production and consumption of steel billets is significant and plays a crucial role in the construction and manufacturing sectors worldwide. Steel billets are semi-finished products that are used as raw material for the production of various steel products. In terms of production, several countries are major players in steel billet manufacturing. China, which is the largest producer of steel globally, accounts for a significant portion of the global steel billet production. Other prominent producers include India, Japan, Russia, the United States, and Turkey. These countries have well-established steel industries and infrastructure to support large-scale production. The consumption of steel billets is driven by the demand for steel products across various sectors. Construction and infrastructure development are the primary drivers of steel billet consumption, as steel is widely used in the construction of buildings, bridges, roads, and other structures. The automotive industry is another major consumer of steel billets, as they are used for manufacturing automobile parts and components. It is challenging to provide an exact figure for the global production and consumption of steel billets due to the constantly changing market dynamics and varying industry reports. However, it is estimated that global steel production exceeded 1.8 billion metric tons in 2020, with a substantial portion of this production being in the form of steel billets. The consumption of steel billets is closely linked to the overall steel demand, which is influenced by economic growth, infrastructure development, industrial activity, and construction projects worldwide. Overall, the global production and consumption of steel billets are significant, reflecting the importance of steel as a crucial material in various industries. The continuous growth in infrastructure development and industrialization across the globe is expected to further drive the production and consumption of steel billets in the coming years.

- Q: How do steel billets contribute to the overall aesthetics of a structure?

- Steel billets, which are essentially semi-finished steel products, play a significant role in enhancing the overall aesthetics of a structure. While their primary purpose is to provide strength and support, their visual appeal should not be underestimated. First and foremost, steel billets are responsible for the creation of various architectural elements, such as columns, beams, and decorative features. These elements not only serve structural purposes but also contribute to the overall aesthetics of the building. The clean lines and sleek appearance of steel billets can give a modern and contemporary feel to the structure, adding a touch of sophistication and elegance. Moreover, steel billets can be manipulated and shaped into intricate designs and patterns, making them highly versatile in terms of aesthetics. Whether it is a grand entrance gate, a unique staircase railing, or an ornate decorative panel, steel billets can be molded and fabricated to create visually appealing and eye-catching features that enhance the overall charm of the structure. Furthermore, steel billets can be finished with various coatings, such as paint, powder coating, or galvanization, which not only provide protection against corrosion but also contribute to the aesthetic appeal. These finishes allow for customization, as they can be chosen to complement the overall design and color scheme of the structure, creating a cohesive and visually pleasing look. In addition, steel billets can be used in combination with other materials, such as glass or wood, to create stunning architectural features. The contrast between the strength and rigidity of steel and the transparency or warmth of other materials can create a visually striking effect, adding depth and interest to the structure's design. Lastly, steel billets offer a sense of durability and timelessness to the structure. The inherent strength and resilience of steel give the impression of solidity and longevity, which are essential factors in creating an aesthetically pleasing building. The sleek and modern appearance of steel billets can also evoke a sense of progress and innovation, enhancing the overall aesthetic appeal of the structure. In conclusion, steel billets contribute to the overall aesthetics of a structure by providing structural support, allowing for intricate designs, offering customization options, creating contrasts with other materials, and conveying a sense of durability and timelessness. Their visual appeal, along with their strength and versatility, makes steel billets an essential component in creating an aesthetically appealing and architecturally pleasing structure.

- Q: What are the common surface defects in steel billets during cooling?

- There are several surface defects that can occur during the cooling process of steel billets. These defects can be caused by factors such as improper handling, inadequate cooling techniques, or impurities in the material. Some of the most common surface defects observed in steel billets during cooling are as follows: 1. Scale Formation: When the steel is exposed to air during the cooling process, a thin layer of oxides called scale forms on its surface. This can result in a rough and uneven surface, which diminishes the overall quality of the billet. 2. Cracks: Thermal stresses induced in the steel during cooling can lead to the formation of cracks. These cracks can be longitudinal, transverse, or even intergranular, and they compromise the structural integrity of the billet. 3. Lamination: Insufficient bonding during the cooling process can cause layers or sheets of steel to separate, resulting in lamination defects. This weakens the billet and reduces its overall strength. 4. Shrinkage Cavities: As the steel solidifies and contracts during cooling, voids or cavities called shrinkage cavities can form on the surface of the billet. These cavities weaken the steel and affect its mechanical properties. 5. Surface Roughness: Inadequate cooling techniques can cause uneven cooling and rapid solidification, ultimately leading to a rough and uneven surface texture on the billet. This defect affects the surface finish of the billet and subsequent processing. 6. Decarburization: Exposure to high temperatures and oxygen during the cooling process can cause the surface of the billet to lose carbon content, resulting in decarburization. This reduces the hardness and strength of the affected areas. To minimize these surface defects, it is crucial to implement proper cooling techniques, including controlled cooling rates, the use of protective coatings, and appropriate handling practices. Regular inspection and quality control measures are also essential to identify and rectify any defects during the cooling process, ensuring the production of high-quality steel billets.

- Q: What is the difference between a steel billet and a steel bar?

- A steel billet and a steel bar are both raw materials used in the manufacturing industry, particularly in the production of metal products. However, there are certain differences between the two. 1. Shape and Size: A steel billet is typically a rectangular or square-shaped semi-finished product with a larger cross-section than a steel bar. It is usually produced through continuous casting or hot rolling processes and has a relatively rough and uneven surface. On the other hand, a steel bar is a long and cylindrical-shaped product that is often obtained by further processing the steel billet through processes like hot rolling, cold drawing, or machining. Steel bars have a smoother and more finished surface. 2. Manufacturing Process: Steel billets are generally produced directly from molten steel through continuous casting or by solidifying the liquid steel in molds. This results in a solid block of steel that is later processed into various shapes. Steel bars, however, are obtained from the steel billets through additional manufacturing processes, such as hot rolling, which involves passing the billet through a series of rolling mills to reduce its size and shape it into a bar. 3. Uses and Applications: Steel billets are primarily used as raw material for further processing, such as forging, extrusion, or rolling, to manufacture various end products like bars, rods, wire, pipes, or structural components. Steel bars, on the other hand, are widely used in construction, manufacturing, and engineering industries for applications that require strength, durability, and a consistent shape. They are used as reinforcement in concrete structures, as shafts or axles in machinery, or as components in the automotive industry. In summary, a steel billet is an intermediate product obtained through casting or hot rolling, while a steel bar is a finished product obtained by further processing the billet. The billet has a larger cross-section and rougher surface, while the bar is cylindrical with a smoother surface. Both billets and bars have distinct uses in the manufacturing industry, with billets serving as raw material for various products and bars being utilized in a wide range of applications that require strength and durability.

Send your message to us

Steel Billets CarbonQ275/3SP in China Square Billets for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords