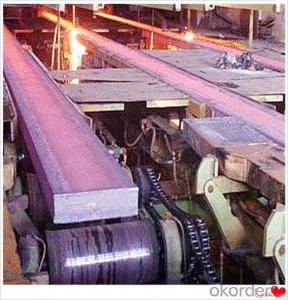

Carbon Steel Billets Square Billets 5sp 3sp& Q235

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Tianjin, China (Mainland) | Brand Name: | cnbm | Grade: | 3SP,5SP,Q235,20MnSi. |

| Shape: | Square | Length: | 5.8-12m or as per request | Standard: | GB |

| Technique: | Hot Rolled | Dimensions: | 100*100-150*150mm | Alloy Or Not: | Non-alloy |

| Secondary Or Not: | Non-secondary | place of origin: | Tianjin | MOQ: | 1O tons at least one container |

| trade term: | FOB, CIF, CFR | packing: | in bundles,seaworthy packing | delivery date: | 15-20 days after receiving the down payment or LC. |

| payment term: | Down payment 30% T/T and balance 70% T/T or L/C. | Carbon Steel Billets with Max Carbon: | 0.30% |

Packaging & Delivery

| Packaging Details: | in bundles |

| Delivery Detail: | within 25 days after we received your advanced payment |

| PRODUCT NAME | Carbon Steel Billets Square Billets |

| material | 3SP,5SP,Q235,20MnSi. |

| size | 100*100MM

120*120MM

130*130MM

150*150MM

|

| length | 6M,9M,12M or as per request |

| capability | 20000MT PER MONTH |

| technique | hot rolled |

| certification | GB |

| delivery time | within 25 days after we received your advanced payment |

| packing | in bundles |

Thanks for your interest on our product carbon square steel billets. If you have any special requirments , please feel free to contanct us.

We would reply you in the first time.

Best regards.

- Q: How are steel billets used in the manufacturing of power plant equipment?

- Due to their exceptional strength and durability, steel billets play a vital role in the production of power plant equipment. These billets serve as the primary material from which various parts and components necessary for power plant machinery are shaped and formed. One significant application of steel billets in power plant equipment manufacturing is the fabrication of turbine blades. These blades are exposed to high temperatures, immense pressures, and rotational forces. Steel billets are carefully chosen for their mechanical properties, such as high tensile strength and resistance to corrosion and fatigue, to ensure the blades can withstand the demanding operating conditions. Additionally, steel billets are employed in the production of generator rotors and stators. These components convert mechanical energy into electrical energy. The strength and stability of steel billets enable them to endure the intense magnetic fields and rotational forces generated by the generator, guaranteeing reliable and efficient power generation. Furthermore, steel billets are used in the manufacturing of boilers and pressure vessels, which are vital for the power generation process. These vessels endure high pressures and temperatures, and steel billets with outstanding heat resistance and pressure containment properties are utilized to ensure the safety and dependability of the power plant equipment. In conclusion, the superior strength, durability, and resistance to extreme conditions make steel billets indispensable in the manufacturing of power plant equipment. Whether it be for turbine blades, generator components, or pressure vessels, steel billets play a critical role in ensuring the reliable and efficient operation of power plants.

- Q: How are steel billets used in the manufacturing of food processing machinery?

- Steel billets are used in the manufacturing of food processing machinery as they provide the raw material for shaping and forming various components of the machinery, such as gears, shafts, and frames. The high strength and durability of steel billets ensure that the machinery can withstand the rigorous demands of food processing operations and maintain its functionality and longevity.

- Q: What are the potential applications of steel billets in the textile industry?

- Steel billets can be used in the textile industry for various applications such as in the manufacturing of textile machinery, equipment, and components. They can be used to produce durable and sturdy parts like spindles, rollers, frames, and looms, which are essential for efficient textile production. Additionally, steel billets can be used in the construction of textile factories and warehouses, providing strength and stability to the infrastructure.

- Q: Can steel billets be used in the production of electrical components?

- Yes, steel billets can be used in the production of electrical components. Steel billets can be shaped and processed into various forms such as bars, rods, or sheets, which are commonly utilized in the manufacturing of electrical components like connectors, terminals, or conductive parts. The steel's high strength, durability, and electrical conductivity make it suitable for these applications.

- Q: How are steel billets reheated before rolling or forging?

- Steel billets are reheated before rolling or forging through a process known as billet heating. This process involves subjecting the billets to high temperatures to make them more malleable and easier to shape. There are several methods commonly used for billet heating, including: 1. Furnaces: The most common method of reheating steel billets is through the use of furnaces. These furnaces are typically gas-fired and can reach temperatures of up to 1,200 degrees Celsius. The billets are loaded into the furnace and heated for a specific period of time to achieve the desired temperature. The furnace provides a controlled environment, allowing for even heating and uniformity. 2. Induction heating: Another method used for reheating steel billets is induction heating. This process utilizes electromagnetic induction to heat the billets. An alternating current is passed through a copper coil, creating a magnetic field. The billets are then placed inside the coil, and the magnetic field induces eddy currents within the billets, generating heat. Induction heating offers precise temperature control and rapid heating rates, making it suitable for high-speed production. 3. Electric resistance heating: Electric resistance heating is another technique employed for reheating steel billets. This method involves passing an electric current through the billets, causing them to heat up due to the resistance encountered. Electric resistance heating can be achieved using various types of heating elements, such as graphite electrodes or resistance heating wires. This method offers precise temperature control and is commonly used for smaller-scale operations. Regardless of the heating method used, it is essential to carefully control the temperature and heating time to ensure the billets reach the optimal temperature for rolling or forging. The reheating process allows the steel to become more pliable, reducing its hardness and increasing its ductility, making it easier to shape and form into the desired end product.

- Q: What are the applications of steel billets?

- Steel billets are primarily used as raw material in the production of various steel products such as bars, rods, wire, and seamless tubes. They are also used in the manufacturing of components for automotive, construction, and machinery industries. Additionally, steel billets can be further processed to produce forgings, which are used in heavy machinery and equipment.

- Q: Is the reaction of carbon and carbon dioxide a redox reaction?

- According to the increase or decrease of the oxidation number, the redox reaction can be split into 2.5 reactions: the half reaction of increasing oxidation number is called the oxidation reaction, and the reaction of reducing the oxidation number is called the reduction reaction.In the reaction, the oxidizing substance, called the reducing agent, forms the oxidation product. The reducing reaction substance is called the oxidant, and the reduced product is produced. The oxidation product is oxidized but weaker than the oxidant; the reducing product is reductive but weaker than the reducing agent.Whether a chemical reaction belongs to an oxidation-reduction reaction depends on whether the reaction has an increase in the number of oxidation, or whether there is an electronic gain or loss.Turn left and turn right |In this reaction, carbon dioxide carbon has a valence of +4 price, after the reaction of carbon monoxide in the carbon price is +2, the carbon dioxide is reduced to carbon monoxide; elemental carbon has a valence of 0 by the price to rise to +2 price, is oxidized to carbon monoxide; carbon is oxidized to carbon dioxide reduction.

- Q: What industries rely heavily on steel billets?

- The industries that heavily rely on steel billets include construction, automotive, aerospace, and manufacturing.

- Q: How do steel billets contribute to the manufacturing of telecommunications devices?

- Steel billets are used in the manufacturing of telecommunications devices as they provide the necessary raw material for various components such as brackets, frames, and chassis. These billets are shaped and processed into specific forms to create the structural support and durability required for these devices. Additionally, steel billets allow for efficient heat dissipation, electromagnetic shielding, and overall product stability, making them essential in the manufacturing process of telecommunications devices.

- Q: What is the difference between steel billets and steel bars?

- Steel billets and steel bars are both raw forms of steel, but they differ in terms of their shapes and sizes. Steel billets are larger, rectangular-shaped semi-finished products that are typically used as input material for further processing, such as rolling or forging. On the other hand, steel bars are smaller, cylindrical-shaped finished products that have undergone additional processing, such as hot or cold rolling, to achieve a desired shape and size. In summary, steel billets are the starting point in the steel production process, while steel bars are the end products ready for use in various applications.

Send your message to us

Carbon Steel Billets Square Billets 5sp 3sp& Q235

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords