Steel Square Billets for construction Q195 and Q235 Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

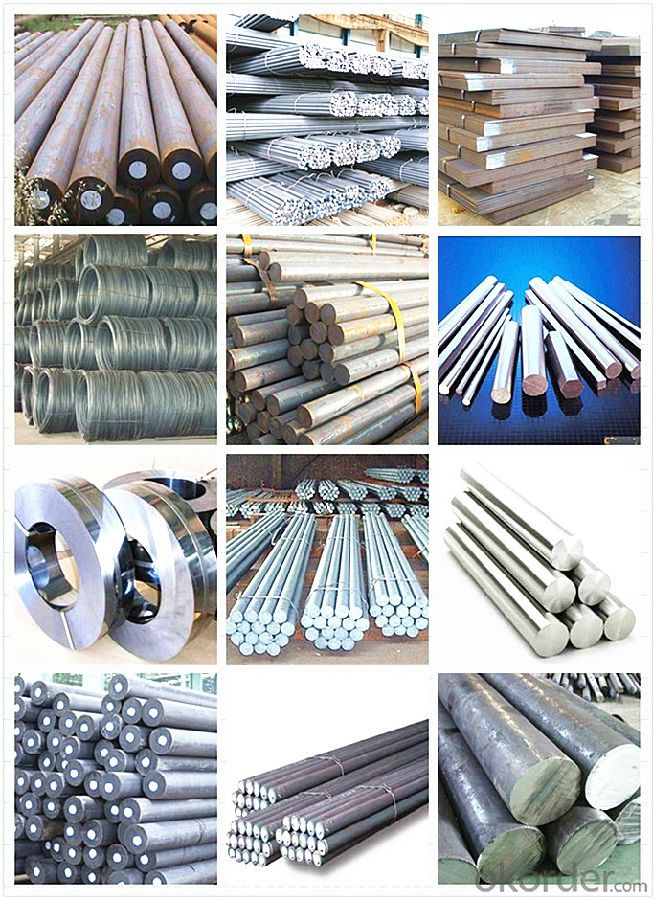

You Might Also Like

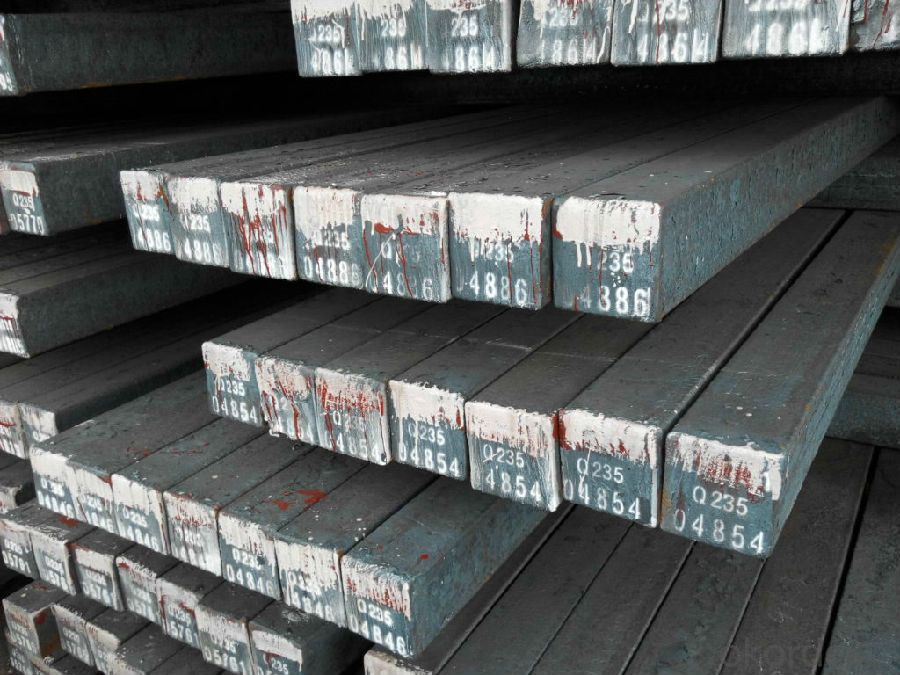

Product Description of Steel Square Billets for construction Q195 and Q235 Materials

| GRADE | SIZE | APPLICATION |

Q195/ 215 | 100mm*100mm*6m | REBAR |

| 120mm*120mm*6m | ||

| 130mm*130mm*6m/12m | ||

| 150mm*150mm*6m/12m |

Chemical Compositon of Steel Square Billets for construction Q195 and Q235 Materials

Q195/ 215 | C (%) | Si (%) | Mn (%) | P(%) | S(%) |

| 0.06-0.12 | 0.15-0.30 | 0.35-0.50 | 0.045% Max | 0.045Max |

Technology process of Steel Square Billets for construction Q195 and Q235 Materials

1.Heat the EVA film

2.Cover the heated EVA film on the mould(can be made from wood or aluminum)

3.Spray a coating in a certain baume degree

4.Put on the empty blask

5.Sand-up the flask and vibrate to compaction

Packaging & Delivery of Steel Square Billets for construction Q195 and Q235 Materials

Packaging Details:containers

Delivery Detail:Complete one set of equipment needs for three months

The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

Products Show

FAQ:

1.Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent

customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department

of these factories. Also CNBM is the holding company of many factories.

4. Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5. Trading Terms?

EXW, FOB, CIF, FFR, CNF

6. After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business

partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different types of defects found in steel billets?

- There are several types of defects that can be found in steel billets. Some common ones include surface defects like cracks, scars, and scale; internal defects like inclusions, segregations, and voids; and dimensional defects such as uneven size or shape. These defects can affect the quality and strength of the steel, so it is important to identify and address them during the manufacturing process.

- Q: What are the specifications for tool steel billets used in the tooling industry?

- The specifications for tool steel billets used in the tooling industry vary depending on the specific application. However, some common specifications include high hardness, excellent wear resistance, good toughness, and high thermal conductivity. Additionally, tool steel billets typically have specific chemical compositions and are often heat treated to achieve desired properties such as high strength and durability.

- Q: How are steel billets used in the manufacturing of furniture and fixtures?

- Steel billets are an essential component in the manufacturing of furniture and fixtures due to their versatility and durability. These billets, which are semi-finished metal products, serve as the raw material for creating various components of furniture and fixtures. One common use of steel billets in furniture manufacturing is for creating frames and structural supports. The billets are shaped and cut into specific dimensions to form the framework of chairs, tables, and other pieces of furniture. The strength and rigidity of steel make it a preferred choice for ensuring the stability and longevity of these products. In addition to frames, steel billets are used for producing hardware components of furniture and fixtures. This includes hinges, locks, drawer slides, and other mechanisms that require strength and precision. By using steel billets, manufacturers can ensure that these components can withstand the wear and tear associated with daily use. Steel billets are also utilized in the production of decorative elements in furniture and fixtures. They can be molded, bent, or welded into various shapes and designs to add aesthetic appeal to the final product. These decorative elements may include trimmings, accents, or ornamental details that enhance the overall appearance of furniture and fixtures. Furthermore, steel billets are often used in the manufacturing of fixtures such as shelving units, display racks, and storage systems. The durability and load-bearing capacity of steel make it an ideal material for constructing these items, ensuring that they can withstand heavy loads and provide long-term support. In summary, steel billets play a crucial role in the manufacturing of furniture and fixtures. They are used to create frames, hardware components, decorative elements, and various types of fixtures. Their strength, durability, and versatility make them an essential raw material for producing high-quality and long-lasting furniture and fixtures.

- Q: What are the main challenges in the recycling of steel billets?

- Several challenges arise when it comes to recycling steel billets, which are semi-finished steel products. The recycling process of steel billets includes several main challenges: 1. Contamination: Throughout their usage, steel billets can become contaminated with various materials such as oil, grease, paint, or other metals. Removing these contaminants and ensuring the purity of the recycled steel can be a complex and costly process. 2. Sorting and segregation: Steel billets come in different grades and sizes, requiring them to be sorted and segregated accordingly for effective recycling. This necessitates advanced sorting technologies and manual labor to ensure that the correct billets are recycled in the appropriate manner. 3. Energy consumption: The recycling of steel billets involves melting and reprocessing the steel, which demands a significant amount of energy. This energy consumption presents a challenge as it contributes to greenhouse gas emissions and increases the overall environmental impact of the recycling process. 4. Infrastructure and logistics: The collection, transportation, and processing of steel billets necessitate a well-established infrastructure and logistics network. Insufficient facilities or transportation can impede the efficient recycling of steel billets. 5. Economic viability: The economic viability of recycling steel billets can be challenging, especially when the cost of recycling exceeds the value of the recycled material. This can discourage recycling efforts and lead to a greater reliance on primary steel production. 6. Consumer awareness and participation: It is crucial to educate consumers about the importance of recycling steel billets and encourage their participation in recycling programs. Lack of awareness and indifference towards recycling can hinder the collection of steel billets for recycling purposes. 7. International trade barriers: In certain cases, trade barriers and import/export restrictions can affect the recycling of steel billets. These barriers can limit the flow of recycled steel billets across different countries, impacting the overall recycling capacity and market dynamics. To address these challenges, a collaborative effort between industries, governments, and consumers is necessary. Investments in research and development, technological advancements, and policy support can help overcome these challenges and promote the sustainable recycling of steel billets.

- Q: How can steel billets be customized for specific applications?

- Steel billets have the potential to be tailored to specific applications using a variety of techniques and processes. One commonly used method involves subjecting the billets to controlled heating and cooling cycles, known as heat treatment, in order to modify their mechanical properties. This can involve processes like annealing, quenching, tempering, or normalizing, which can help achieve desired levels of hardness, toughness, or ductility. Another way to customize steel billets is through alloying, which involves adding specific elements like chromium, nickel, or molybdenum to the steel composition. This enhances the properties of the billets to meet the requirements of different applications. For instance, adding chromium can improve corrosion resistance, while nickel can enhance strength and toughness. Moreover, the shape and size of steel billets can be customized. Depending on the intended use, billets can be cast into various shapes such as round, square, or rectangular, to better suit their purpose. Additionally, the dimensions of the billets can be adjusted to specific requirements, allowing for more efficient processing and minimizing material waste. Surface treatments can also be applied to steel billets to further customize them for specific applications. These treatments, including shot blasting, pickling, or coating, improve the surface finish, remove impurities, and provide protection against corrosion. Overall, the customization of steel billets for specific applications involves a combination of heat treatment, alloying, shaping, and surface treatments. Through these processes, the mechanical properties, composition, shape, and surface characteristics of the billets can be fine-tuned to meet the specific requirements of different industries and applications.

- Q: What are the main factors that influence the strength of steel billets?

- The main factors that influence the strength of steel billets are the chemical composition, heat treatment, and microstructure of the steel. The chemical composition of steel billets plays a significant role in determining their strength. The presence of alloying elements such as carbon, manganese, silicon, and chromium can enhance the strength of steel by forming solid solutions or precipitates that increase the hardness and tensile strength of the material. Additionally, controlling the impurity levels and ensuring the desired balance of alloying elements is crucial in achieving the desired strength properties. Heat treatment is another crucial factor that influences the strength of steel billets. The heat treatment process involves heating the steel to a specific temperature, followed by cooling at a controlled rate. This process can significantly affect the microstructure of the steel, which in turn impacts its strength. For instance, quenching and tempering can result in the formation of a desired microstructure, such as martensite or bainite, which enhances the strength and toughness of the steel. The microstructure of steel billets is a key factor in determining their strength. The arrangement of the crystal grains and the presence of various phases within the steel can greatly influence its mechanical properties. Fine-grained structures generally exhibit higher strength due to a greater number of grain boundaries, which inhibit dislocation movement and enhance strength. Additionally, the presence of specific microstructural features, such as precipitates or second-phase particles, can also contribute to the strength of steel billets. Furthermore, factors such as the manufacturing process, cooling rate during solidification, and mechanical working (such as rolling or extrusion) can affect the strength of steel billets. These factors influence the grain size, grain boundary density, and defect concentration, all of which impact the mechanical properties of the steel. In summary, the strength of steel billets is influenced by the chemical composition, heat treatment, and microstructure of the steel. These factors can be carefully controlled and optimized to achieve the desired strength properties for various applications.

- Q: Can steel billets be used in the production of jewelry?

- No, steel billets cannot be used in the production of jewelry. Jewelry is typically made from precious metals such as gold, silver, or platinum, which offer a higher level of aesthetic appeal and value. Steel, being an alloy primarily used in construction and manufacturing industries, lacks the desired characteristics and appearance required for jewelry production.

- Q: How are steel billets used in the manufacturing of structural components?

- The manufacturing of structural components heavily relies on steel billets, which are an essential raw material. These billets, usually square or round in shape, are produced through continuous casting, a process that solidifies molten steel into a semi-finished product. After the formation of steel billets, they undergo further processing using different techniques like hot rolling, forging, or extrusion. Hot rolling includes heating the billets and passing them through a sequence of rollers to shape them into desired profiles, such as beams, channels, or angles. This method is crucial for achieving the necessary dimensions, strength, and surface finish. Forging is another technique employed with steel billets, involving heating the billets and shaping them using compressive forces. It is primarily used for manufacturing components that require enhanced strength and durability, like crankshafts, connecting rods, or turbine blades. Extrusion, on the other hand, is a specialized process that utilizes heated billets to create complex shapes by forcing them through a die. This technique is commonly utilized in the production of tubular components, such as pipes, tubes, or hollow sections. These components are extensively used in the construction of structures like bridges, buildings, or infrastructure. Steel billets play a critical role in the manufacturing of structural components by providing the necessary raw material that can be shaped using various fabrication techniques. Their adaptability and versatility make them an indispensable component in the construction industry, ensuring that buildings and structures possess the required strength and durability to withstand different loads and environmental conditions.

- Q: How are steel billets inspected before they are used in production?

- Steel billets are inspected thoroughly before they are used in production to ensure their quality and adherence to the required specifications. The inspection process typically involves several key steps. Firstly, visual inspection is conducted to examine the surface of the billets for any surface defects such as cracks, seams, or deformities. Any irregularities can indicate potential weaknesses or problems in the billet that may affect its performance during production. Secondly, dimensional inspection is performed to verify the billet's size, length, width, and other critical dimensions. This is crucial to ensure that the billets meet the precise requirements of the production process and can be seamlessly integrated into the manufacturing operations. Thirdly, ultrasonic testing is often employed to detect any internal defects or discontinuities within the billets. Ultrasonic waves are passed through the billet, and any reflections or echoes are analyzed to identify any flaws such as voids, inclusions, or cracks that may compromise the structural integrity of the billets. Additionally, magnetic particle inspection may be carried out to identify surface or near-surface defects that may not be visible to the naked eye. This technique involves applying magnetic particles to the surface of the billet and detecting any magnetic leakage caused by defects through the use of magnetic fields. Furthermore, chemical analysis is frequently performed to ensure that the steel billets have the desired chemical composition. This involves taking samples from the billets and subjecting them to various tests to determine the percentages of different elements present. This analysis guarantees that the billets possess the necessary chemical properties for the intended application. Overall, steel billets undergo a comprehensive inspection process that encompasses visual examination, dimensional verification, ultrasonic testing, magnetic particle inspection, and chemical analysis. This multi-faceted approach ensures that the billets meet the required quality standards and are suitable for use in production, thus minimizing the risk of any performance issues or failures during manufacturing processes.

- Q: What are the main factors affecting the surface quality of steel billets?

- Several factors influence the surface quality of steel billets. Firstly, the cleanliness of the steel is crucial. Impurities like oxides, scale, and inclusions can negatively impact the surface, causing defects such as pits, cracks, and roughness. Secondly, the temperature during the steelmaking process is important. Overheating can result in excessive scaling and oxidation, leading to a poor surface finish. Insufficient heating, on the other hand, can cause a non-uniform surface and inconsistent mechanical properties. Residual stresses also affect the surface quality. Uneven cooling or improper heat treatment can result in surface cracks, warping, or distortion. Surface treatment processes and their effectiveness also impact the surface quality. Grinding, polishing, or shot blasting can improve the surface finish by eliminating defects and creating a smoother surface. The quality of equipment and tools used in steel production plays a significant role as well. Worn-out or poorly maintained machinery can cause surface defects, inadequate surface preparation, or improper handling, thus affecting the final surface quality. Lastly, the composition and microstructure of the steel itself influence the surface quality. Variations in alloying elements, grain size, and phase distribution can affect the surface finish, hardness, and overall quality of the billets. In conclusion, cleanliness, temperature control, residual stresses, surface treatment processes, equipment quality, and steel composition are the main factors that affect the surface quality of steel billets. Proper steelmaking practices, surface treatments, and quality control measures are crucial in achieving high-quality steel billets with superior surface finish.

Send your message to us

Steel Square Billets for construction Q195 and Q235 Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords