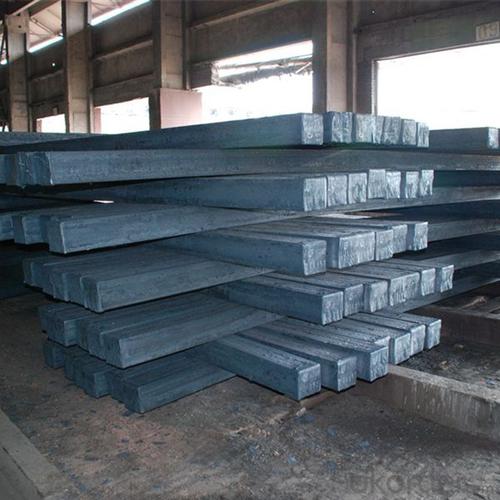

Hot Rolled steel products material Square Bar Steel Billet For Sale 60*60,90*90,100*100,120*120mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Hebei, China (Mainland) | Model Number: | Hot Rolled Square Bar Steel Billet For Sale 60*60,90*90,100*100,120*12 | Grade: | 3SP,5SP,Q195,Q235,20MnSi |

| Chemical Composition: | C,Mn,Ni,Si,P,S,Cr,Cu | Shape: | Square | Length: | 6m,9m,12m |

| Standard: | ASTM | Technique: | Hot Rolled | Dimensions: | 60*60,90*90,100*100,120*120mm |

| Alloy Or Not: | Is Alloy | Secondary Or Not: | Non-secondary | process: | hot rolled |

| material: | Q195,Q235,3SP,5SP | specification: | 60*60,90*90,100*100,120*120mm | length: | 6m,12m |

| type: | low carbon,high carbon | supply ability: | 200,000mts/month | Alloy or not: | Alloy |

| application: | the steel products material | shape: | square | MOQ: | 100mts/each size |

Packaging & Delivery

| Packaging Details: | bude bundle packing |

| Delivery Detail: | within 15-25 days after the prepayment or L/C we received |

Specifications

A.mateiral:Q235B,3/5SP,20MnSi

B.length:6m,9m,12m

C.size:60*60,90*90,100*100,120*120mm

D.supply ability:200,000mts/month

Product Description

Chemical Composition: Carbon

Shape: Square

Length: 6M 9M 12M

Standard: GB

Technique: Hot Rolled

Dimensions: 60*60-130*130mm

Alloy Or Not: Non-alloy

Secondary Or Not: Non-secondary

Packaging & Delivery:

Packaging Detail: In standard packing

Delivery Detail: In 25-30 days

Our advantage:

Guaranteed quality

All specifications available

Goods in stock

Customizable according to order

Credit sales acceptable

Customizing service:

Sizes, length, width, thickness, surface, all of these can be customized according to order.

After service

- Q: Are steel billets used in the production of household appliances?

- Indeed, steel billets find application in the manufacturing of household appliances. Serving as intermediate steel products, steel billets are employed as primary materials across various industries, encompassing the production of household appliances. Following the process of heating, these billets are either rolled or forged into diverse forms and dimensions, thereby fabricating essential components such as sheets, plates, rods, and bars, pivotal in the creation of appliances. Steel, due to its robustness, longevity, and ability to resist corrosion, becomes a favored choice in the realm of household appliances. Consequently, steel is extensively utilized in the production of a wide array of household appliances, including refrigerators, washing machines, dishwashers, ovens, and several others.

- Q: How are steel billets used in the production of wind turbine components?

- Steel billets are an essential raw material used in the production of wind turbine components. These billets are large, semi-finished blocks of steel that serve as the starting point for various manufacturing processes. One of the primary applications of steel billets in wind turbine production is for the fabrication of tower sections. The tower is a crucial component that supports the entire turbine structure, and it needs to withstand strong winds and other environmental conditions. Steel billets are first heated and then rolled or forged into the desired shape and size to create the tower sections. These sections are then welded together to form the complete tower structure. Additionally, steel billets are also used for manufacturing other wind turbine components such as the hub, nacelle, and main shaft. The hub is the central part of the turbine that holds the rotor blades, while the nacelle houses the generator and other critical components. Both these parts require high-strength steel, which can be obtained by processing steel billets. Similarly, the main shaft, which connects the rotor hub to the gearbox, needs to be extremely durable and able to withstand the torque generated by the blades. The choice of using steel billets in wind turbine production is driven by the material's exceptional mechanical properties. Steel exhibits high strength, allowing the turbine components to withstand the extreme forces they experience during operation. Moreover, steel also possesses excellent fatigue resistance, which is crucial considering the continuous rotation and cyclic loading of wind turbines. Overall, steel billets play a vital role in the production of wind turbine components, ensuring the structural integrity and reliability of these renewable energy systems. By using steel billets, manufacturers can fabricate strong and durable components that contribute to the efficient and sustainable generation of wind power.

- Q: How can steel billets be customized for specific applications?

- Steel billets can be customized for specific applications through a variety of processes and techniques. One common method is heat treatment, where the billets are subjected to controlled heating and cooling cycles to alter their mechanical properties. This can include processes such as annealing, quenching, tempering, or normalizing, which help to achieve desired levels of hardness, toughness, or ductility. Another way to customize steel billets is through alloying. By adding specific elements to the steel composition, such as chromium, nickel, or molybdenum, the properties of the billets can be enhanced to meet the requirements of different applications. For example, adding chromium can improve corrosion resistance, while nickel can enhance strength and toughness. Furthermore, the shape and size of steel billets can also be customized. Depending on the application, billets can be cast into various shapes, such as round, square, or rectangular, to better suit the intended use. Additionally, the dimensions of the billets can be tailored to specific requirements, allowing for more efficient processing and minimizing material waste. In addition to these methods, surface treatments can be applied to steel billets to further customize them for specific applications. This can include processes like shot blasting, pickling, or coating, which improve the surface finish, remove impurities, and provide protection against corrosion. Overall, steel billets can be customized for specific applications through a combination of heat treatment, alloying, shaping, and surface treatments. These processes allow for the fine-tuning of the mechanical properties, composition, shape, and surface characteristics of the billets to meet the specific requirements of different industries and applications.

- Q: What is the global production and consumption of steel billets?

- The global production and consumption of steel billets vary each year based on market demand and economic factors. However, steel billets are a crucial raw material in the steel industry, used for further processing into various steel products. The production and consumption of steel billets are significant in countries with a robust steel industry, such as China, India, the United States, and Russia. Accurate figures for global production and consumption can be obtained from industry reports and statistical data provided by organizations like the World Steel Association.

- Q: What are the main factors that determine the sustainability of steel billets production?

- Several key factors determine the sustainability of steel billets production. Firstly, the choice of raw material source plays a crucial role. Utilizing recycled scrap metal as the primary raw material reduces the need for new mining and extraction of iron ore, thus minimizing the environmental impact associated with resource extraction. Secondly, sustainability is influenced by energy consumption during the production process. Given that steel production is energy-intensive, the type of energy sources utilized greatly impacts sustainability. The adoption of renewable energy, such as solar or wind power, can significantly reduce the carbon footprint of steel billets production. Thirdly, the efficiency of production processes and technologies employed is vital for sustainability. Modern technologies, like electric arc furnaces, offer higher energy efficiency and emit fewer greenhouse gases compared to traditional blast furnaces. Additionally, implementing waste heat recovery systems and optimizing material usage further enhances the sustainability of steel billets production. Proper management of by-products and waste generated during production is another crucial factor. Ensuring appropriate handling, treatment, and disposal of by-products and waste materials, such as slag and dust, is essential to minimize environmental pollution and ensure sustainability. Furthermore, the overall sustainability of steel billets production is influenced by the adoption of responsible and ethical practices throughout the supply chain. This includes upholding labor rights, maintaining health and safety standards, and engaging with the community. Lastly, regulatory frameworks and government policies have a significant impact on sustainability. Stringent environmental regulations, support for clean technologies, and incentives for sustainable practices can encourage the industry to adopt more environmentally friendly production methods. In conclusion, the sustainability of steel billets production is determined by factors such as the raw material source, energy consumption, production processes, waste management, ethical practices, and regulatory frameworks. By addressing these factors, the steel industry can strive towards more sustainable and environmentally friendly production practices.

- Q: What are the main properties of steel billets?

- Steel billets serve as the initial material for various steel products and possess several important properties that make them suitable for further shaping and processing. To begin with, steel billets demonstrate a high level of strength and durability. This is primarily attributed to the composition of steel, which consists mainly of iron with small amounts of carbon and other elements. This composition provides steel billets with exceptional mechanical properties, including high tensile strength and resistance to deformation. Moreover, steel billets exhibit favorable heat transfer properties. Steel is renowned for its efficient heat conductivity, making it an ideal material for applications requiring thermal conductivity, such as the production of automotive parts or construction materials. Furthermore, steel billets possess excellent machinability. Machinability refers to the ease with which a material can be shaped or formed using various machining processes. Steel billets can be easily cut, drilled, and shaped into desired forms, enabling efficient processing and fabrication. Additionally, steel billets display superb weldability. Steel is known for its compatibility with welding processes, enabling the joining of different steel components or the repair of damaged steel structures. This property is crucial in numerous industries, including construction, automotive, and shipbuilding. Lastly, steel billets have a high level of recyclability. Steel is one of the most widely recycled materials globally, with a significant portion of steel production derived from recycled steel. This environmentally friendly aspect makes steel billets an excellent choice as they can be recycled and repurposed multiple times without losing their properties. In conclusion, steel billets possess high strength and durability, favorable heat transfer properties, excellent machinability and weldability, and a high level of recyclability. These properties establish steel billets as a versatile and extensively used material in various industries, spanning from construction and manufacturing to automotive and aerospace.

- Q: How do steel billets contribute to the manufacturing of construction products?

- Steel billets are an essential raw material in the manufacturing of construction products because they serve as the starting point for various steel products. These billets are transformed into different shapes and sizes through processes like rolling, forging, or extrusion, allowing them to be used in the construction of structures such as beams, columns, bars, and rods. The high strength and durability of steel billets make them ideal for withstanding heavy loads and adverse weather conditions, ensuring the safety and longevity of construction projects.

- Q: What are the different types of rolling processes used for shaping steel billets?

- There are several different types of rolling processes used for shaping steel billets. Some of the commonly used processes include hot rolling, cold rolling, ring rolling, and skew rolling. Each process has its own advantages and is suitable for specific applications. Hot rolling involves heating the steel billet to a high temperature and then passing it through a series of rollers to shape it. Cold rolling, on the other hand, is performed at room temperature and is used to achieve tighter tolerances and improved surface finish. Ring rolling is used to produce seamless rings by gradually shaping the billet using a combination of axial and radial forces. Skew rolling is a specialized process used for producing balls or cylindrical shapes by rotating the billet at an angle to the rolling direction. Overall, these rolling processes offer various techniques to shape steel billets according to specific requirements.

- Q: What are the main factors affecting the thermal expansion of steel billets?

- The main factors affecting the thermal expansion of steel billets include temperature, composition of the steel, and the grain structure of the material.

- Q: How do steel billets contribute to the overall safety of a structure?

- Steel billets play a significant role in contributing to the overall safety of a structure in several ways. Firstly, steel billets serve as the raw material for manufacturing steel bars, beams, columns, and other structural components. These components are widely used in construction due to their high strength and durability. By using steel billets as the starting material, the resulting steel products exhibit excellent load-bearing capacity, which enhances the structural integrity of the building. Moreover, steel billets undergo a rigorous manufacturing process that includes various quality control checks. These checks ensure that the billets possess consistent and reliable mechanical properties, such as high tensile strength and impact resistance. As a result, when these billets are used in the construction of a structure, they contribute to its overall safety by providing a reliable and robust framework that can withstand external forces, such as wind, earthquakes, or heavy loads. Additionally, steel billets are often produced using advanced metallurgical techniques, such as controlled cooling or heat treatment, to achieve specific properties required for structural applications. These processes help in improving the microstructure of the steel, reducing internal defects, and enhancing its resistance to corrosion, fatigue, and other forms of degradation. This, in turn, increases the lifespan of the structure and minimizes the risk of structural failure, thus ensuring the safety of the occupants. Furthermore, steel billets can be manufactured with precise dimensions and tolerances, allowing for accurate and efficient construction. This precision in fabrication ensures that structural components fit together seamlessly, reducing the likelihood of gaps, misalignments, or weak points that could compromise the safety of the structure. Lastly, steel billets are highly recyclable, making them an environmentally friendly choice for construction. By opting for steel billets, the construction industry can reduce its carbon footprint and contribute to sustainable development. This focus on sustainability aligns with the overall safety of a structure, as a sustainable approach ensures the long-term stability and resilience of the built environment. In conclusion, steel billets contribute to the overall safety of a structure by providing high-strength, durable, and reliable materials for construction. Their consistent mechanical properties, resistance to external forces, improved microstructure, and precise fabrication ensure a strong and secure framework. Moreover, their recyclability promotes sustainability, further enhancing the long-term safety and integrity of the structure.

Send your message to us

Hot Rolled steel products material Square Bar Steel Billet For Sale 60*60,90*90,100*100,120*120mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords