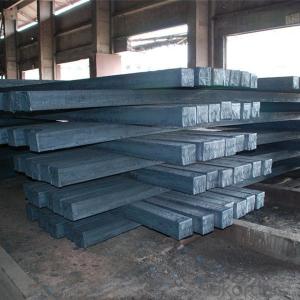

Square Steel Bar, Steel Billets Exporter (60X60-150X150)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Description:

| Product Name | Steel Billets |

| Size | 60×60mm, 100×100mm, 120×120mm, 130×130mm, 150×150mm |

| Length | 6M, 9M, 12M |

| Grade | Q195, Q235, Q275, 3SP, 5SP, 20MnSi, etc |

| Standard | ASTM, GB, JIS |

| Chemical Composition | Q235: C: 0.14-0.22% MN: 0.3-0.7% SI: 0.3% max P: 0.045%max S: 0.045%max |

| Q275 C: 0.27-0.38% MN: 0.5-0.8% SI: 0.3% max P: 0.045%max S: 0.045%max | |

| According to Customers Needs | |

| Delivery | 10-30 Days |

Detailed Image:  Production Process Image:

Production Process Image:  Shipment:

Shipment:

Logistic department established and serves for sales department. Cargo is delivered to the port by our own trucks. Both bulk and container service are available and cargo shipment is in hands of logistic staffs.

FAQ:

1: Do You Have Mills?

Yes, we have our own mills and had invested in other mills for advanced products. Besides this, we have our registered trading company for resources integration.

2: What Is Your Main Products?

We are the earliest company that researched and developed ASTM steel angles channels, and exported to USA and Canada in 2006. And we also developed JIS & En standard angles channels and I beams and exported to South Korea, South East Asia and Middle East market. Now, structural steel products, wire rod, steel plate and steel billets are all available in our company.

3: Have You Passed Global Quality System Management?

Yes, certificate was given in 2007.

4: Do You Have A Quality Check Team?

Yes, our quality check team could provide serious quality check services.

5: How About The Machine?

Continues Rolling Lines are supplied in our company. We could produce according to our guest's needs. And chemical elements and physical properties could be controlled to fit needs.

- Q: How is steel used in the production of tools and hardware?

- Steel is commonly used in the production of tools and hardware due to its strength, durability, and versatility. It can be forged, shaped, and tempered to create various types of tools such as wrenches, hammers, screwdrivers, and saw blades. Steel's hardness allows it to withstand heavy use and resist wear and tear, making it ideal for tools that require high strength and toughness. Additionally, steel can be easily machined and sharpened, enabling the production of precise cutting edges and intricate designs, further enhancing its utility in the manufacturing of tools and hardware.

- Q: How is steel wire rope inspected for fatigue and wear?

- Steel wire rope is inspected for fatigue and wear through visual examination and non-destructive tests. This includes inspecting the rope for signs of corrosion, broken wires, or distorted strands. Additionally, magnetic particle inspection and ultrasonic testing are often used to detect hidden defects and measure the rope's internal condition. Regular inspections and maintenance help ensure the integrity and safety of steel wire ropes.

- Q: How do steel products contribute to the construction of theaters and concert halls?

- Steel products contribute to the construction of theaters and concert halls in various ways. Firstly, steel is commonly used for the structural framework of these buildings, providing strength, stability, and the ability to span large distances. Additionally, steel is used for roofing, cladding, and facade systems, offering durability and aesthetic appeal. Steel is also utilized in the construction of balconies, stairs, and seating structures, ensuring safety and comfort for the audience. Overall, steel products play a crucial role in creating modern, functional, and visually appealing theaters and concert halls.

- Q: What are the different types of steel sheets and their applications?

- There are several different types of steel sheets, each with their own unique properties and applications. Some common types include hot rolled steel sheets, cold rolled steel sheets, galvanized steel sheets, and stainless steel sheets. Hot rolled steel sheets are typically used in construction and manufacturing industries due to their high strength and durability. They are commonly used for structural components, such as beams and columns, as well as for automotive and machinery parts. Cold rolled steel sheets are known for their smooth surface finish and tight dimensional tolerance. They are often used in applications that require precise shapes and sizes, such as appliances, furniture, and automotive body panels. Galvanized steel sheets are coated with a layer of zinc to prevent corrosion and rust. They are commonly used in outdoor structures, such as roofing and siding, as well as in automotive parts and electrical equipment. Stainless steel sheets are highly resistant to corrosion and staining, making them suitable for a wide range of applications. They are commonly used in kitchen appliances, food processing equipment, medical devices, and architectural structures. Overall, the choice of steel sheet depends on the specific requirements of the application, such as strength, finish, corrosion resistance, and cost.

- Q: What are the applications of steel gratings in industrial walkways?

- Steel gratings are widely used in industrial walkways due to their durability, strength, and versatility. These applications provide a safe and sturdy surface for workers to navigate through various industrial settings, such as factories, power plants, refineries, and construction sites. The open design of steel gratings allows for efficient drainage of liquids, preventing slip hazards and enhancing worker safety. Additionally, their robust construction can withstand heavy loads and provide excellent resistance to corrosion, making them ideal for long-term use in demanding environments.

- Q: How are steel products used in the construction of theme-based resorts and hotels?

- Steel products are widely used in the construction of theme-based resorts and hotels due to their durability, strength, and versatility. They can be used in various structural elements such as beams, columns, and trusses, ensuring the stability and safety of the building. Additionally, steel is often utilized for designing iconic features and architectural elements, such as unique facades, grand entrances, and intricate detailing. Its ability to withstand extreme weather conditions and support heavy loads makes it an ideal choice for constructing large, expansive spaces within resorts and hotels. Overall, steel products play a crucial role in creating visually appealing and structurally sound theme-based resorts and hotels.

- Q: How are steel gratings used in the construction of staircases and platforms?

- Steel gratings are commonly used in the construction of staircases and platforms to provide a sturdy and safe walking surface. These gratings are typically installed as treads or platforms, allowing for efficient drainage and ventilation while ensuring stability and strength. The open design of the gratings also offers enhanced visibility, making them a popular choice in industrial and commercial settings where safety is paramount.

- Q: How do steel products contribute to the food and beverage industry?

- Steel products contribute to the food and beverage industry in various ways. Steel is commonly used in the construction of commercial kitchens and food processing plants due to its durability, hygiene, and resistance to corrosion. Stainless steel equipment, such as work surfaces, sinks, and storage units, provide a clean and safe environment for food preparation and storage. Steel tanks and containers are used for transportation and storage of food and beverages, ensuring their freshness and preventing contamination. Additionally, steel packaging, such as cans and beverage containers, offers a secure and long-lasting solution for preserving and distributing food and drinks.

- Q: What are the factors to consider when selecting the right type of steel for a specific application?

- When selecting the right type of steel for a specific application, there are several factors to consider. These include the required strength and hardness, corrosion resistance, weldability, formability, and cost. Additionally, factors such as the environment in which the steel will be used, the load-bearing requirements, and any specific industry standards or regulations must also be taken into account. Overall, a thorough understanding of the application's requirements and careful consideration of these factors will ensure the selection of the most suitable type of steel.

- Q: How does steel pipe threading for fire sprinkler systems work?

- Steel pipe threading for fire sprinkler systems involves the process of cutting threads onto the ends of steel pipes to create a tight and secure connection between the pipes and fittings. This threading allows for the easy installation and assembly of the fire sprinkler system components, ensuring a reliable and leak-free system.

Send your message to us

Square Steel Bar, Steel Billets Exporter (60X60-150X150)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords