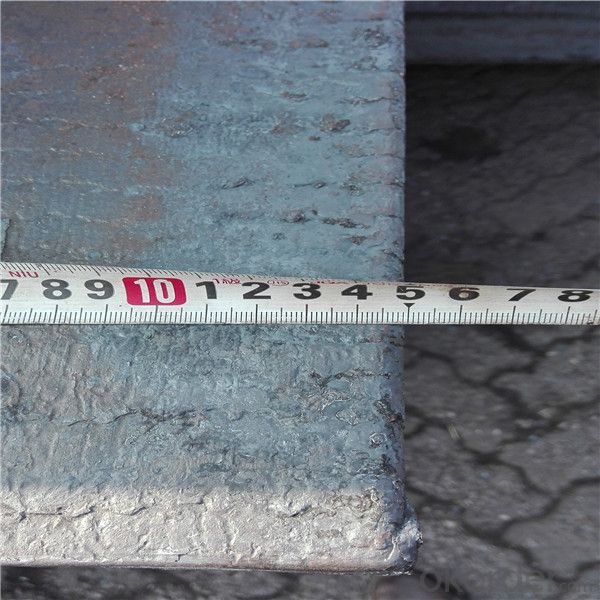

China newly Square Steel Billets Size 60-150mm 3sp/ 5sp for sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15597 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into

more functional shapes and sizes. While they have already been put in the furnace, they still require a series

of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in

hardware stores, or used for different applications. The unformed billets, however, can be used in striking

currency such as coins and as reserves, similar to gold bars.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Payment terms: 100%Irrevercable L/C at sight or T/T

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q:What are the different types of steel billet manipulation equipment?

- In the steel industry, there exists a variety of steel billet manipulation equipment. These machines serve the purpose of handling and manipulating semi-finished steel billets, which later undergo further processing to acquire different shapes and forms. The types of steel billet manipulation equipment are as follows: 1. Billet grabbers: Equipped with either hydraulic or mechanical arms, these machines possess the ability to securely grip and lift steel billets. They are commonly utilized for the loading and unloading of billets from storage areas, trucks, or trains. 2. Billet pushers: These machines find their utility in pushing steel billets along a conveyor system or into a furnace for additional processing. They are generally equipped with hydraulic systems that provide the necessary force to move the billets. 3. Billet transfer cars: Specialized vehicles, known as billet transfer cars, are employed for transporting steel billets within a steel plant. These vehicles feature a flat surface on which billets can be placed and moved from one location to another. 4. Billet cutting machines: These machines are dedicated to cutting steel billets into smaller pieces or removing excess material. They come in various configurations, such as circular saws, shearing machines, or abrasive cutting machines, and can be operated either manually or automatically. 5. Billet heating equipment: This category encompasses induction heating systems or furnaces used to heat steel billets to a specific temperature for further processing. These machines are indispensable in numerous heat treatment processes, including annealing or quenching. 6. Billet straightening machines: These machines are responsible for rectifying any deformations or bends that may occur during the billet manufacturing process. By applying controlled pressure and tension, they ensure that the billets are perfectly straight before proceeding to further processing. 7. Billet inspection equipment: These machines serve the purpose of inspecting the quality and dimensions of steel billets. They employ various techniques, such as ultrasonic testing, magnetic particle testing, or visual inspection, to identify any defects or flaws in the billets. Each type of steel billet manipulation equipment plays a vital role in the steel manufacturing process, guaranteeing the efficient handling, processing, and quality control of steel billets before they undergo transformation into finished products.

- Q:Are steel billets used in the production of musical instruments?

- Yes, steel billets are commonly used in the production of musical instruments. They are often used to create various components such as keys, valves, and rods, which are essential parts of instruments like saxophones, trumpets, and trombones.

- Q:What are the main factors that influence the strength of steel billets?

- The main factors that influence the strength of steel billets are the chemical composition, heat treatment, and microstructure of the steel. The chemical composition of steel billets plays a significant role in determining their strength. The presence of alloying elements such as carbon, manganese, silicon, and chromium can enhance the strength of steel by forming solid solutions or precipitates that increase the hardness and tensile strength of the material. Additionally, controlling the impurity levels and ensuring the desired balance of alloying elements is crucial in achieving the desired strength properties. Heat treatment is another crucial factor that influences the strength of steel billets. The heat treatment process involves heating the steel to a specific temperature, followed by cooling at a controlled rate. This process can significantly affect the microstructure of the steel, which in turn impacts its strength. For instance, quenching and tempering can result in the formation of a desired microstructure, such as martensite or bainite, which enhances the strength and toughness of the steel. The microstructure of steel billets is a key factor in determining their strength. The arrangement of the crystal grains and the presence of various phases within the steel can greatly influence its mechanical properties. Fine-grained structures generally exhibit higher strength due to a greater number of grain boundaries, which inhibit dislocation movement and enhance strength. Additionally, the presence of specific microstructural features, such as precipitates or second-phase particles, can also contribute to the strength of steel billets. Furthermore, factors such as the manufacturing process, cooling rate during solidification, and mechanical working (such as rolling or extrusion) can affect the strength of steel billets. These factors influence the grain size, grain boundary density, and defect concentration, all of which impact the mechanical properties of the steel. In summary, the strength of steel billets is influenced by the chemical composition, heat treatment, and microstructure of the steel. These factors can be carefully controlled and optimized to achieve the desired strength properties for various applications.

- Q:How do steel billets contribute to the manufacturing of HVAC systems?

- The role of steel billets in the manufacturing of HVAC systems is crucial. These systems rely on strong and durable components to ensure efficient operation and longevity, and steel billets serve as the foundation for such components. To begin with, steel billets are utilized to construct the primary structural framework of HVAC systems. This framework, also known as the casing or housing, offers support and protection for the internal components including heat exchangers, fans, and coils. Steel billets possess high strength and rigidity, making them an ideal choice for creating a sturdy and dependable framework that can withstand the various stresses and strains encountered during system operation. Furthermore, steel billets are employed in the production of various internal components of HVAC systems. For instance, steel billets are commonly used to manufacture heat exchangers, which play a crucial role in transferring heat between the air and the refrigerant. Steel's high thermal conductivity and corrosion resistance make it an excellent material for these critical components, ensuring efficient heat transfer and long-term performance. Moreover, steel billets are utilized in the manufacturing of ductwork. Ductwork consists of a network of pipes or channels that distribute conditioned air throughout a building. Steel billets are often rolled and formed into the necessary shapes to create the ducts. The strength and durability of steel guarantee that the ductwork can withstand the pressure differentials and mechanical stresses associated with air movement, thereby maintaining the integrity of the system and preventing leaks. Additionally, steel billets are essential for the production of HVAC system supports and brackets. These components are responsible for securely mounting various equipment, such as air handling units or condensing units. Steel's strength and load-bearing capacity make it an ideal material for ensuring the stability and proper installation of these crucial elements. In conclusion, steel billets are vital in the manufacturing of HVAC systems as they provide the necessary strength, durability, and thermal properties for the structural framework, internal components, ductwork, and supports. Without steel billets, it would be extremely challenging to produce HVAC systems that deliver efficient heating, ventilation, and air conditioning to buildings.

- Q:How are steel billets recycled or reused?

- Steel billets can be recycled or reused in several ways. One common method is through the process of melting and casting, where the billets are melted down and formed into new steel products. They can also be used as raw material in the production of other steel products, such as bars, rods, or pipes. Additionally, steel billets can be further processed and shaped into various components for construction, automotive, or manufacturing industries. This recycling and reusing of steel billets helps to conserve resources, reduce waste, and lower the environmental impact of steel production.

- Q:How do steel billets contribute to the overall cost-effectiveness of a project?

- Steel billets contribute to the overall cost-effectiveness of a project in several ways. Firstly, steel billets are the starting material for various steel products, such as beams, bars, and sheets. By using steel billets, manufacturers can produce these products in a cost-effective manner, as billets are usually cheaper than finished steel products. Moreover, steel billets allow for efficient use of resources. They can be easily melted down and molded into different shapes and sizes, minimizing waste during the production process. This flexibility reduces the amount of raw material required, leading to cost savings. Furthermore, steel billets have excellent strength and durability properties. By using steel billets in construction projects, engineers can ensure that the structures are sturdy and long-lasting. This helps to reduce maintenance and repair costs over time, making the project more cost-effective in the long run. Additionally, steel billets are readily available in the market, making them a cost-effective choice for projects with tight timelines. Manufacturers can easily source steel billets from various suppliers, ensuring a steady supply of material for the project. Lastly, steel billets contribute to cost-effectiveness through their recyclability. Steel is one of the most recycled materials globally, and using recycled steel billets can significantly reduce the cost of production. Recycling steel billets also helps to minimize the environmental impact of a project, making it a more sustainable and cost-effective option. Overall, steel billets play a vital role in the cost-effectiveness of a project by providing a cost-effective starting material, minimizing waste, ensuring durability, offering availability, and promoting recycling.

- Q:How are steel billets used in the manufacturing of industrial pumps?

- Steel billets are used in the manufacturing of industrial pumps as a starting material for the production of various pump components. These billets are typically made of high-quality steel and serve as the raw material for forging or casting processes. Firstly, steel billets are used in the production of pump casings. The billets are shaped into the desired form, either by forging or casting, to create the outer shell of the pump. This casing provides structural integrity and contains the fluid being pumped. Additionally, steel billets are utilized in the manufacturing of impellers, which are vital components of industrial pumps. Impellers are responsible for generating the necessary force to move the fluid through the pump. The billets are machined, shaped, and polished to form the intricate design of the impeller, ensuring optimal fluid flow and efficiency. Furthermore, steel billets are used for manufacturing shafts and other critical components of the pump. These components require high strength and durability to withstand the demanding conditions of industrial applications. By using steel billets, manufacturers can ensure the necessary mechanical properties are met, such as resistance to corrosion, wear, and high temperatures. In summary, steel billets play a crucial role in the manufacturing of industrial pumps. They serve as the starting material for various pump components, including casings, impellers, shafts, and more. By using high-quality steel billets, manufacturers can produce durable and efficient pumps that meet the demanding requirements of industrial applications.

- Q:What shape is the billet?

- Material standardThickness range: 150-240mm +/-5mm, width range: 880-1530mm +/-20mmLength range: 3700-10000mm +/-500mmCross section size: 64*64; 82*82; 98*98; 124*124; 152*170mm; 120*150; 152*164;Length: 9000mmSection tolerance: square billet: +1.0/-2.0----+3.0/-1.0mm slab: width: +/-2.0MM thickness: +/-3.0MMLength tolerance: +/-200MMDiagonal tolerance of section: 3.5-8.0MMBillet cross section dimension requirements: <1242MM, not allowed; =1242MM, <=2MM, >1242MM, <=3MMBreaking (shear) expansion deformation: <1242MM square billet: no control; slab: <=15MMSurface inclination: no more than 0.1 of the bloomBending length: not more than 10MM per 1MTwist: length <=5M, <=11. Length <=7.5M, <=5.Material 3SP/PS, chemical composition,%:C, Mn, Si, S, P

- Q:How can the quality of steel billets be improved?

- The quality of steel billets can be improved through various methods such as enhancing the raw material selection, refining the manufacturing process, implementing stringent quality control measures, and adopting advanced technologies. These measures can include using high-quality iron ore and scrap metal as raw materials, employing advanced refining techniques like vacuum degassing and ladle furnace treatment, optimizing the casting and rolling processes, and implementing non-destructive testing methods to detect any defects. Additionally, continuous monitoring of the production parameters and implementing a robust quality management system can contribute to further improving the quality of steel billets.

- Q:Are steel billets used in the production of electrical transmission towers?

- The utilization of steel billets is widespread in the manufacturing of electrical transmission towers. At the onset of the production process, steel billets serve as the primary form of steel. They are typically shaped and sized through hot rolling, resulting in various sections and components required for constructing transmission towers. Due to its remarkable strength and durability, steel emerges as the perfect material for such structures, which must endure harsh environmental conditions and uphold heavy electrical conductors. Additionally, steel possesses exceptional electrical conductivity properties, a vital characteristic for ensuring the efficient transmission of electricity through the towers. In summary, steel billets assume a pivotal role in the creation of electrical transmission towers, guaranteeing their strength, durability, and efficiency.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

China newly Square Steel Billets Size 60-150mm 3sp/ 5sp for sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15597 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords