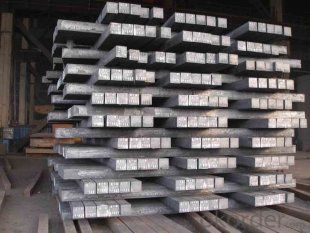

Steel Billet for Basic Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Description

Mainly from the shape is divided into two kinds:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod.,

2. Main Features

Billet was rolled steel, after processing can be used for mechanical parts, forging parts, processing all kinds of steel, steel Q345B channel steel, wire rod is the role of the billet.

3. Excellent Product Image

4. Application

Steel billet is used in the production of semi-finished products, generally cannot be used directly for the society.Steel billets and steel are strictly divided into standard, cannot decide to whether the business enterprise of the final product, and according to unified standards to perform the whole society.Typically, billet and the steel is relatively easy to distinguish, but for some steel billet, and have the same specification and same steel purposes (such as rolling tube billet), whether can be used for other industries, whether through steel processing process, whether through a finished product rolling mill processing to distinguish.

5. FAQ

1.Q: Do you have attended any exhibition?

A: We almost go to Canton Fair and Overseas Exhibitions every year.

2. Q: How to guarantee the quality of the products?

A: We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. Q: How long can we receive the product after purchase?

A: Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

Why choose us?

Pre-sale Service

1. Sample can be offered with sample charge and courier fee by buyer's side.

2. We have full stock,and can deliver within short time.Many styles for your choices.

3. OEM and ODM order are accepted, Any kind of logo printing or design are available.

4. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you

5. All of our products are produce by our professional workman and we have our high-work-effect foreign trust-worthy sales team.

6. We have 18 years' experience of design, manufacture and sell lingerie, we cherish every order from our honor.

After you choose

1. Count the most efficient shipping cost and make invoice to you at once.

2. Check quality again, then send out to you at 1-2 working day after your payment.

3. Email you the tracking no, and help to chase the parcels until it arrive you.

- Q: What's the difference between a cold plate and a hot plate?

- Hair straightenerrollhead, tail tongue shapeand thefishtail shape, thickness, width of poor accuracy, edgehaswavy, folding, tower and other defects. The coil weight is heavy, and the inner diameter of the steel coil is 760mm. (general management industry likes to use. Thestraightthroughcutting) cutting head, tail cutting, trimming and multipass straightening and leveling finishing line processing, cutting board or heavy volume, which becomes: hot rolled steel plate and flat steel coils, slittingstripand other products. Hot finishing rolling by pickling descaling and oil is made by pickling hot-rolled coils. This product has the tendency to replace the cold rolled plate locally, the price is moderate, and is well liked by the customers.

- Q: What are the standards for cold rolling and hot rolling of stainless steel? What's the difference?

- The free torsion rigidity of hot rolled steel is higher than that of cold rolled steel, so the torsion resistance of hot rolled steel is better than that of cold rolled steel.

- Q: Stamping process classification

- Is a kind of basic stamping process mould separation material, which can be directly made of flat parts or other stamping processes such as bending, drawing and forming are blank, also can be in the stamping forming has been carried on the incision, trimming etc.. Blanking is widely used in automotive, household appliances, electronics, instruments, meters, machinery, railways, communications, chemicals, light industry, textiles and aerospace industries. Blanking accounts for about 50% to 60% of the whole stamping process. Bending: bending of sheet metal, fittings, and profiles into a plastic forming method of angles, curvatures, and shapes. Bending is one of the main processes widely used in the production of stamping parts. The bending of metal material is essentially an elastic-plastic deformation process, after unloading, the workpiece will produce the direction of the elastic recovery, called rebound. Springback affects the accuracy of the workpiece, and it is the key technology that must be considered in the bending process.

- Q: What kind of steel is Q2351?

- Q stands for the yield limit of this material, and the latter 235 refers to the yield of this material, around 235MPa. With the increase of the thickness of the material, the yield value will be reduced. Due to the moderate carbon content and good comprehensive properties, the strength, plasticity and welding properties will be better matched and the most widely used.

- Q: Stainless steel composite process

- Rolling composite method is a method of producing metal stainless steel composite plate by using pressure process. There are two kinds of cold rolling composite and hot rolling composite. The basic principle is the need of two kinds of metal compound in certain proportion and requirements into the rolling mill, rolling mill in great pressure, or with thermal effect by combining the two kinds of metallic composite plate occurred in the whole cross section of plastic deformation, prompting to composite surface deformation, clean and activation. Along with the formation of planar metallurgical bonding. The basic requirement of rolling compound is the rolling equipment with great pressure and the professional technology of producing composite board. The stainless steel composite plate made by this method has the following advantages: (1) it can enlarge the dimension (length and width) of the composite panel. (2) the production cost is low, and the products are competitive in the market. (3) from raw materials to finished products can be continuously produced, suitable for mass production. (4) it is easy to set up a production line with higher automation. (5) the composite material is not easy to be contaminated by the base material, the combination property is good, and the product quality is stable.

- Q: What is a metal layered composite?

- Large plastic deformation methodLarge plastic deformation refers to the pressure of rolling mill under the powerful, or heat to combine, to be two metal compound within the metal composite on the surface of the plastic deformation, rupture, and metallurgical solid planar formation in the diffusion of the subsequent heat treatment in combination.The large plastic deformation is divided into two kinds: rolling, compounding and extrusion.

- Q: How to recognize the raw plate in the steel plate?

- With the continuous casting slab or as raw material for hot plate, after reheating furnace heating, descaling into the roughing mill of high pressure water, roughing material by cutting head, tail, and then enter the finishing mill, the implementation of the computer controlled rolling, after finishing through the laminar cooling (computer controlled cooling rate and coiling machine volume) take, become straight hair volume.

- Q: What's the difference between stainless steel strip 304 hot rolling and cold rolling?

- The cold rolled plate is mainly made of thin plate and rolled by plate at room temperature. Usually, subsequent surfaces are subjected to pickling, polishing, and passivation. The price at the factory level, of course, is expensive for cold rolling

- Q: What are the raw materials and production processes of steel?

- The hot metal from the torpedo car can be poured into the converter as the main burden after being treated by desulphurization and slag disposal, etc., with the addition of scrap steel below 10%. Then, burning into the converter oxygen blowing, excess carbon in molten iron by oxidation and release large amounts of heat, when the probe is measured to reach a predetermined low carbon content, namely stop blowing and tapping. In general, the ladle needs to be deoxidized and adjusted to operate the ingredients. Then, the carbonized rice hull is cast on the surface of the liquid steel to prevent the molten steel from being oxidized and sent to the continuous casting or die casting work area. For high requirement steel, increasing bottom blowing argon, RH vacuum treatment, spraying powder treatment (spraying SI - CA powder and denatured lime) can effectively reduce gas and inclusion in steel, and further reduce carbon and reduce sulfur. After these measures are refined, the ingredients can be adjusted to meet the demand of high quality steel.

Send your message to us

Steel Billet for Basic Building Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords