Steel Frame SF-140 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

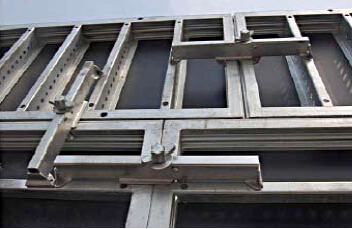

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

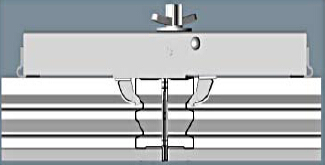

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q: Can steel formwork be used for projects with limited formwork assembly time?

- Projects with limited formwork assembly time can indeed utilize steel formwork. Renowned for its durability and strength, steel formwork proves to be an apt choice for projects necessitating swift assembly and demobilization. In contrast to conventional timber formwork, steel formwork offers effortless assembly and disassembly, thereby reducing overall construction duration. Furthermore, steel formwork's reusability facilitates cost savings and heightened efficiency for subsequent projects. In summary, steel formwork emerges as a dependable resolution for projects with restricted formwork assembly time.

- Q: How do steel formwork systems differ from one another?

- Steel formwork systems can differ from one another in several ways. Firstly, they can vary in terms of their design and construction. Some steel formwork systems are modular, meaning they consist of pre-assembled panels that can be easily connected and adjusted to form different shapes and sizes. Others may be custom-made for specific projects, offering more flexibility in terms of formwork design. Secondly, steel formwork systems can differ in terms of their strength and durability. Some systems are designed to withstand heavy loads and extreme conditions, making them suitable for large-scale construction projects. Others may be lighter and more portable, making them ideal for smaller projects or areas with limited access. Another factor that distinguishes steel formwork systems is their ease of use. Some systems are designed to be user-friendly, with features such as built-in handles, adjustable brackets, and easy-to-use locking mechanisms. These systems allow for quick and efficient installation and dismantling, saving time and effort on the construction site. Additionally, steel formwork systems can differ in terms of their finishing options. Some systems offer smooth and precise finishes, ideal for projects that require a high-quality surface. Others may have textured or patterned finishes, providing a decorative element to the concrete structure. Lastly, steel formwork systems can differ in terms of their cost and availability. Some systems may be more affordable and readily available, making them a popular choice for smaller projects or budget-conscious contractors. Other systems may be more expensive or require longer lead times for fabrication, but offer advanced features or customization options. Overall, the differences between steel formwork systems lie in their design, strength, ease of use, finishing options, and cost. Contractors and construction professionals should carefully evaluate these factors to select the most suitable steel formwork system for their specific project requirements.

- Q: Can steel formwork be used for both residential and infrastructure projects?

- Yes, steel formwork can be used for both residential and infrastructure projects. Steel formwork offers numerous advantages such as high strength, durability, and reusability, making it suitable for a wide range of construction applications. In residential projects, steel formwork can be utilized for building foundations, walls, slabs, and columns, providing a robust and efficient solution. Similarly, in infrastructure projects, steel formwork can be employed for constructing bridges, tunnels, highways, and other large-scale structures. Its versatility allows for customization to meet specific project requirements and can withstand heavy loads and adverse weather conditions. Furthermore, steel formwork's ability to be easily assembled, disassembled, and reused makes it a cost-effective option for both types of projects. Overall, steel formwork is a highly adaptable and practical choice for various construction purposes, making it suitable for both residential and infrastructure projects.

- Q: How does steel formwork compare to aluminum formwork in terms of performance?

- Steel and aluminum formwork are commonly used materials in the construction industry to create temporary molds or structures that hold concrete in place until it becomes solid. When comparing these materials, it is important to consider their performance aspects. In terms of performance, steel formwork is known for its strength and durability. It can withstand heavy loads and rough handling, making it suitable for heavy-duty applications. Steel formwork also maintains its shape during the concrete pouring process, resulting in accurate finishes. It can be easily customized to meet project requirements. On the other hand, aluminum formwork is preferred for its lightweight nature. It is easy to handle, transport, and assemble, reducing labor costs and construction time. It also has excellent corrosion resistance, making it suitable for coastal areas or humid environments. Additionally, aluminum formwork provides a smooth surface finish on the concrete, requiring minimal treatment. The choice between steel and aluminum formwork depends on the specific project requirements. Steel formwork is ideal for projects with heavy loads or high reuse needs due to its strength and durability. On the other hand, aluminum formwork is a better choice for projects that require quick assembly, easy handling, and a smooth surface finish. Ultimately, the selection of formwork should be based on a careful evaluation of the project's needs, budget, timeline, and other factors such as cost, maintenance, and environmental impact.

- Q: What are the considerations when designing steel formwork for water tanks?

- When designing steel formwork for water tanks, there are several important considerations that need to be taken into account. These considerations include structural integrity, corrosion resistance, water tightness, and ease of construction. Firstly, structural integrity is crucial when designing steel formwork for water tanks. The formwork needs to be able to withstand the weight of the water and any additional loads such as surcharge or seismic forces. It is important to calculate the required thickness and reinforcement of the steel plates to ensure that they can safely support the weight of the water and prevent any structural failure. Secondly, corrosion resistance is another key consideration. Water tanks are constantly exposed to moisture, which can lead to the formation of rust and corrosion on the steel formwork. To mitigate this, it is important to use corrosion-resistant steel or apply protective coatings to the formwork. These coatings should be able to withstand the constant exposure to water and prevent any degradation of the steel. Water tightness is another crucial consideration when designing steel formwork for water tanks. The formwork needs to be able to retain the water without any leakage. This requires careful design and construction techniques such as proper sealing joints, welding, and the use of waterproofing materials. It is essential to ensure that there are no gaps or weak points in the formwork that could lead to water leakage. Lastly, ease of construction is an important consideration when designing steel formwork for water tanks. The formwork should be designed in such a way that it can be easily assembled and disassembled, allowing for efficient construction and maintenance. It is important to consider factors such as modular construction, ease of access for workers, and the use of appropriate lifting equipment. In conclusion, when designing steel formwork for water tanks, it is important to consider factors such as structural integrity, corrosion resistance, water tightness, and ease of construction. By carefully considering these factors, one can ensure the durability, functionality, and longevity of the water tank.

- Q: How does steel formwork handle different concrete shrinkage characteristics?

- Steel formwork is a versatile and durable option for concrete construction projects, and it is designed to handle different concrete shrinkage characteristics effectively. Concrete shrinkage refers to the reduction in volume of the concrete as it dries and hardens. One of the main advantages of steel formwork is its strength and rigidity. Steel is a highly robust material that can withstand the pressure and forces exerted by the shrinking concrete. This ensures that the formwork remains intact and stable during the entire curing process, regardless of the concrete's shrinkage characteristics. Additionally, steel formwork is highly adjustable and can be easily modified to accommodate different concrete shrinkage rates. This flexibility allows contractors to adapt the formwork system to the specific needs of the project, ensuring that any potential issues related to shrinkage are effectively addressed. Moreover, steel formwork provides excellent support for the concrete during the curing process, minimizing the risk of cracking or deformation caused by shrinkage. Its smooth and non-absorbent surface helps to prevent excessive moisture loss from the concrete, which can contribute to increased shrinkage. By maintaining a controlled environment, steel formwork helps to regulate the drying process and reduce the overall shrinkage of the concrete. In summary, steel formwork is well-suited to handle different concrete shrinkage characteristics due to its strength, adjustability, and ability to provide optimal support and moisture control. This makes it a reliable and efficient choice for concrete construction projects, ensuring the integrity and longevity of the structure.

- Q: What are the different types of tie systems used in steel formwork?

- There are several types of tie systems used in steel formwork, including through ties, external ties, and snap ties. Through ties are typically used for large wall formwork, where steel rods are inserted through the formwork and secured with nuts and plates on both sides. External ties are used for smaller wall panels, where steel rods are attached to the exterior of the formwork and anchored to the ground or surrounding structures. Snap ties are commonly used for column formwork, where metal or plastic cones are inserted into the formwork and secured with a metal snap tie. These tie systems provide stability and strength to the steel formwork during concrete pouring and curing.

- Q: What are the factors to consider when selecting steel formwork?

- When selecting steel formwork, there are several factors to consider. 1. Strength and durability: Steel formwork should be strong enough to withstand the weight of the concrete and the forces applied during the pouring and curing process. It should also be able to withstand multiple uses without losing its structural integrity. 2. Flexibility and adaptability: The formwork should be able to be easily adjusted and modified to accommodate different shapes and sizes of concrete elements. This is particularly important in construction projects that involve complex or irregular structures. 3. Ease of assembly and dismantling: The formwork system should be quick and easy to assemble and dismantle, as this can significantly impact the overall construction timeline. The use of standardized components and a simple connection system can contribute to faster assembly and dismantling. 4. Surface finish: The quality of the surface finish of the concrete is important, especially for architectural projects. Steel formwork should provide a smooth and even surface, without any visible marks or imperfections, to ensure a high-quality end result. 5. Cost-effectiveness: The overall cost of the formwork system, including the initial investment, maintenance, and reusability, should be considered. While steel formwork may have a higher upfront cost compared to other materials, its durability and reusability can make it a cost-effective choice in the long run. 6. Safety: The safety of workers during the construction process is paramount. Steel formwork should be designed and manufactured with safety features such as non-slip surfaces, secure connections, and adequate bracing to prevent accidents or collapses. 7. Environmental impact: The environmental impact of the formwork material should also be taken into account. Steel formwork is often considered more environmentally friendly compared to traditional timber formwork due to its reusability and recyclability. By considering these factors, construction professionals can make an informed decision when selecting steel formwork that meets their project requirements and delivers optimal results.

- Q: Types of building templates? What is the clear water template

- 2 steel template: in addition to the combination of steel templates, has developed a wide steel template, all steel large formwork, light large steel mold, steel frame, such as 63 steel template. The high cost of steel mold, in addition to large projects such as bridges or other buildings, nuclear power plants, reservoirs and other construction sites, has been replaced by building wooden template.

- Q: What are the common maintenance practices for steel formwork?

- To ensure the steel formwork's optimal performance, various maintenance practices should be followed. These include regular cleaning and inspection, lubrication of movable parts, repair of any damage or wear, and appropriate storage when not in use. To maintain cleanliness, it is crucial to remove any concrete residue, dirt, or debris that may accumulate on the formwork. This can be achieved by using water, a mild detergent, and a stiff brush. Caution should be exercised to avoid abrasive materials or chemicals that may harm the steel. It is necessary to conduct routine inspections to identify signs of wear, damage, or corrosion. This should be done both before and after each use of the formwork. Any cracks, deformations, or loose parts should be promptly repaired or replaced to ensure the formwork remains safe and functional. Lubricating moving parts, such as hinges, locks, and adjustable components, is of utmost importance to guarantee smooth operation. Applying a suitable lubricant to these parts helps prevent rust, corrosion, and sticking. This practice helps maintain the formwork's functionality and ease of use. Repairing any damage or wear is vital to uphold the structural integrity of the formwork. Swift action should be taken to repair any cracks or deformations using appropriate methods like welding or reinforcing. Damaged parts must be replaced with new ones to uphold the formwork's strength and stability. Proper storage is essential to prolong the lifespan of steel formwork and prevent damage. It should be stored in a dry and well-ventilated area to avoid corrosion. Additionally, formwork should be stacked or stored in a manner that prevents distortion or bending of the steel components. Furthermore, protecting the formwork from moisture and excessive heat is crucial to avoid potential damage. By adhering to these common maintenance practices, the steel formwork can be preserved in excellent condition, ensuring its durability and reliability for future use.

Send your message to us

Steel Frame SF-140 for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords