Stair Tower for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

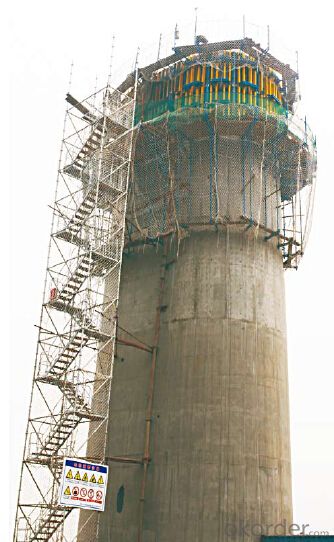

Stair Tower

The structure of ring-lock stair tower is the same as Φ60 ring lock scaffolding.

The dimension of cross section is 1500×3000mm.It is widely used in construction.

Bearing Capacity of Stair Tower:

The stair tower can be erected with the maximum height of 150m,

when attached to the wall every 4.5m.

- Q: What are the different types of reinforcement systems used with steel formwork?

- There are several types of reinforcement systems used with steel formwork, including tie rods, form ties, waler systems, and shoring systems.

- Q: How does steel formwork contribute to the overall structural integrity of a building?

- Steel formwork plays a crucial role in contributing to the overall structural integrity of a building. Firstly, steel formwork provides a robust framework for pouring and shaping concrete, ensuring that it maintains the desired shape and dimensions during the construction process. This is particularly important for complex or irregular structures, where the use of steel formwork allows for accurate and precise construction. Furthermore, steel formwork offers excellent strength and durability, which enhances the structural integrity of the building. Steel is inherently strong and can withstand heavy loads, making it suitable for supporting the weight of concrete and other construction materials. This strength ensures that the formwork remains stable and secure, preventing any potential collapse or deformation during the construction process. Additionally, steel formwork provides excellent dimensional stability, which is vital for maintaining the structural integrity of the building. Steel is resistant to warping, shrinking, or expanding due to changes in temperature or humidity, ensuring that the formwork retains its shape and does not compromise the structural stability of the building. Moreover, the use of steel formwork allows for efficient and speedy construction, which can also contribute to the overall structural integrity of the building. Steel formwork systems are reusable and can be easily assembled and disassembled, enabling faster construction cycles. This reduces the risk of errors or delays, ensuring that the building is constructed in a timely manner and minimizing potential structural issues that may arise from prolonged construction periods. In conclusion, steel formwork is essential for ensuring the overall structural integrity of a building. Its robustness, strength, dimensional stability, and efficiency contribute to the accurate construction and support of the building's structural components, ultimately ensuring its safety and durability.

- Q: How does steel formwork contribute to the overall durability of the structure?

- Steel formwork contributes to the overall durability of a structure in several ways. Firstly, steel is a strong and rigid material that provides excellent support and stability during the concrete pouring process. This ensures that the structure maintains its shape and form accurately, minimizing any potential deformations or cracks. Additionally, steel formwork is highly resistant to corrosion, which helps protect the concrete from moisture and other environmental factors that can weaken its integrity over time. Furthermore, steel formwork can be easily reused multiple times, reducing material waste and increasing cost-effectiveness. Overall, the use of steel formwork enhances the structural strength and longevity of the building, ensuring its durability for years to come.

- Q: What are the disadvantages of using steel formwork?

- One disadvantage of using steel formwork is its relatively high cost compared to other types of formwork materials. Additionally, steel formwork is heavy and requires special equipment for handling and installation, making it less convenient to transport and set up on construction sites. Moreover, steel formwork needs to be properly maintained to prevent rusting and corrosion, which adds to the overall maintenance cost. Lastly, steel formwork may not be suitable for complex and intricate architectural designs that require flexible formwork systems.

- Q: How does steel formwork contribute to the overall acoustics of the structure?

- Steel formwork does not directly contribute to the overall acoustics of a structure as its primary function is to provide support and shape during the construction process. The acoustics of a building are primarily influenced by the design and materials used for the walls, ceilings, and floors, which are usually installed after the steel formwork is removed.

- Q: How does steel formwork perform in earthquake-prone areas?

- Steel formwork performs well in earthquake-prone areas due to its high strength and durability. It can withstand the seismic forces and provide stability to the concrete structure during an earthquake. Its rigid construction helps prevent structural damage and ensures the safety of the building and its occupants.

- Q: What are the common design considerations for steel formwork in high-rise buildings?

- When designing steel formwork for high-rise buildings, there are several important factors to consider. These considerations are crucial for ensuring that the formwork system is structurally sound, safe, and efficient. 1. Load capacity is a key consideration. The formwork must be able to withstand the weight of the concrete, workers, equipment, and other loads without deforming or failing. 2. Stability is also important. High-rise buildings are exposed to external forces like wind and seismic loads, so the formwork system must be stable and resistant to these forces. Proper bracing, tie-downs, and anchorage systems should be included in the design. 3. Durability is essential due to the harsh conditions of construction sites. The steel formwork must be able to withstand moisture, chemicals, and physical impact. Material selection and protective coatings should be carefully chosen to prevent corrosion and ensure long-term durability. 4. Flexibility is necessary because high-rise buildings often have complex geometries. The formwork system should be able to accommodate different floor layouts, wall configurations, and column sizes. Modular formwork systems are commonly used for their flexibility and ease of adjustment. 5. Safety is of utmost importance in high-rise construction. The formwork system should include safety features like non-slip surfaces, guardrails, access platforms, and fall protection systems. Sufficient space for workers to move around and perform their tasks safely should also be considered. 6. Construction timeline is a critical factor. The formwork system should be designed for fast and efficient construction, minimizing downtime and delays. This could involve using pre-fabricated components, easy assembly and disassembly methods, and efficient material handling systems. 7. Cost-effectiveness is another consideration. The design should optimize cost-effectiveness without compromising quality and safety. This includes factors like material selection, formwork reuse, efficient labor usage, and waste reduction. In summary, the design considerations for steel formwork in high-rise buildings revolve around load capacity, stability, durability, flexibility, safety, construction timeline, and cost-effectiveness. By carefully addressing these considerations, designers can ensure a successful and efficient construction process for high-rise buildings.

- Q: How does steel formwork affect the overall safety of a construction project?

- The overall safety of a construction project can be significantly affected by steel formwork. To begin with, steel formwork guarantees that concrete pouring is done in a secure and stable manner, thereby containing and supporting the concrete during its curing process. This eliminates the danger of concrete collapsing or deforming, which could pose a risk to workers and the stability of the entire structure. Furthermore, steel formwork is well-known for its durability and ability to bear heavy loads. This reduces the likelihood of formwork failure or collapse, thus enhancing the safety of workers who are either working on the formwork or in close proximity to it, as they can trust in its stability. Additionally, the design of steel formwork incorporates safety features such as handrails, walkways, and ladder access points, making it easier and safer for workers to access during construction activities. These features minimize the risk of falls and accidents, thereby creating a safer work environment. Moreover, steel formwork allows for precise and accurate construction, resulting in a finished product of higher quality. This reduces the chances of structural defects or weaknesses that could compromise the safety of the building. Steel formwork also provides a smooth and even surface, reducing the risk of tripping hazards and enabling safer movement on the construction site. Lastly, steel formwork is reusable and can be easily dismantled and relocated, reducing waste and minimizing its environmental impact. This not only contributes to sustainability but also reduces the risks associated with handling and disposing of traditional formwork materials. In conclusion, steel formwork has a positive impact on the overall safety of a construction project by providing a strong structure, ensuring stability, offering safety features, enabling precise construction, reducing waste, and promoting a safer work environment.

- Q: How does steel formwork handle different concrete surface gloss levels?

- Steel formwork is a versatile and durable option for dealing with different levels of gloss on concrete surfaces. Its ability to create a consistent and even finish is due to its smooth and rigid nature. When it comes to achieving different levels of gloss on concrete surfaces, steel formwork has several advantages. Firstly, it offers a smooth and uniform surface, which is crucial for achieving a high gloss finish. The steel panels are meticulously constructed to create a seamless surface, minimizing any irregularities that could affect the desired gloss level. In addition, steel formwork is highly resistant to warping or bending under the weight of the concrete. This ensures that the surface remains level and consistent, which is particularly important when aiming for a glossy finish. Any inconsistencies in the formwork could lead to uneven concrete placement and variations in gloss. Moreover, steel formwork is reusable, making it cost-effective and environmentally friendly. With proper maintenance and care, it can be used for multiple projects, ensuring consistent results in terms of gloss levels. In conclusion, steel formwork is an excellent choice for handling different levels of gloss on concrete surfaces. Its smooth and rigid construction guarantees a uniform finish, while its durability ensures consistent results. Steel formwork provides an efficient and effective solution for achieving various gloss levels in concrete construction projects.

- Q: Can steel formwork be used in seismic zones?

- Steel formwork is indeed capable of being employed in seismic zones. Steel possesses formidable strength and durability, enabling it to endure the formidable forces unleashed during an earthquake. The material exhibits a remarkable ability to flex and absorb energy, rendering it highly suitable for deployment in seismic zones. Furthermore, steel formwork confers stability and rigidity upon the structure, guaranteeing its ability to withstand the quivering and shifting caused by seismic activity. Nonetheless, it is essential to take into account other factors such as design, construction techniques, and local building codes to ensure the correct installation and compliance of the steel formwork system with the specific requirements of the seismic zone.

Send your message to us

Stair Tower for formwork and scaffolding systems

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords